Mason Graphite reports that trials using Mason Graphite’s Lac Guéret spherical purified graphite (SPG) with silicon (Si) additions have produced very favorable results. This work program was initially stated in the Company’s press release (June 7th, 2021).

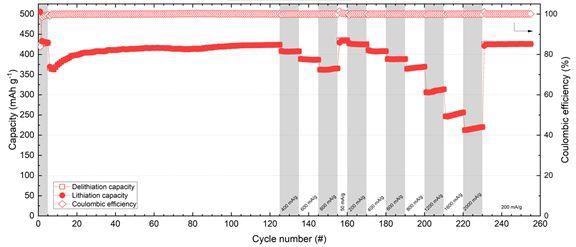

Cycling test results are presented in the graph. Image Credit: Mason Graphite

Cycling test results are presented in the graph. Image Credit: Mason Graphite

Sicona Battery Technologies, one of Mason Graphite’s strategic partners, carried out the work program using its patent-pending approach of integrating carbon, Si nanoparticles, SPG and/or synthetic graphite in creating an economical, high-performance advanced Li-ion battery anode material.

Significant Capacity Increase for Li-ion Batteries Through Si Additions

Si boosts the energy density of Li-ion batteries, enabling more electrical energy storage per unit of anode volume; this would, for instance, translate to a longer range for electric vehicles, while using a battery analogous in size.

Si excellently exhibits a much bigger capacity to store lithium ions, and therefore energy, compared to graphite, but unavoidably swells during charging, causing major mechanical challenges.

The solution presently looked at by the industry involves small additions of Si (usually in the form of silicon-oxide “SiOx”) to graphite-based anode materials upon manufacturing the electrode slurries which boosts the energy density while restricting the swelling to controllable levels. This method is, however, restricted by the high cost of SiOx materials as well as the real-world increases in energy density, rate capability and long-term cycling.

The objective for the first commercial item, established via deliberations by Sicona with numerous probable customers globally, is a composite anode material possessing a primary capacity of 450 milliamperes-hour per gram of material (“mAh/g”) (Sicona “SiG450TM”). This commercial grade is anticipated to be quickly accepted industrially as it can be simply applied in current battery manufacturing processes.

Mason Graphite’s SPG Testing in Si-Composites

These newest series of tests were based on Sicona’s exclusive formulation to create an engineered silicon-graphite-carbon active anode material that incorporates a few percent of Si, carbon and a mixture of Mason Graphite’s SPG and synthetic graphite. The composite anode material was then verified in prototype Li-ion batteries (half coin-cells) by Sicona in an 80:10:10 (AM:BM:CM) formulation.

The highlights include:

- 435 mAh/g capacity, an 19% increase compared to the usual capacity of 365 mAh/g for natural graphite and 22.5% increase above the usual capacity of 355 mAh/g for synthetic graphite;

- The 450 mAh/g commercial objective is projected to be easily realized by Sicona with Mason Graphite’s SPG via the improvement of some of the formulation’s key parameters in forthcoming tests;

- 100% coulombic efficiency after 250 cycles at different rates between 0.5C (2 hours for a complete charge) to 4.6C (13 minutes for a complete charge), which shows the possibility to realize excellent long-term cycling, even after exposing the cell to a series of faster charging rates of 1C, 2C, 3C and 4.6C;

- 100% capacity retention after >250 cycles, and this after finishing a series of charging/discharging rate tests (from 10 hours for a complete charge to 13 minutes for a complete charge);

- Up to 96% retention capability when increasing the cycling rate from 0.1C (10 hours for a complete charge) to 1C (1 hour for a full charge) — a usual target by Korean cell manufacturers is 90% minimum;

- 63% retention capacity when boosting the cycling rate from 1C to 3.7C (16 minutes for a complete charge) and 54% retention capacity when boosting the cycling rate further up to 4.6C (13 minutes for a complete charge). Significantly, when returning the cell to 0.5C cycling, 100% of its original capacity (435 mAh/g) is unchanged;

Cycling tests, such as rate variation tests, are still continuing on the same cells and optimization tests will be performed soon. Tests to accomplish greater capacities (such as 550 mAh/g and 650 mAh/g) and complete pouch cell testing are also scheduled to take place in the near future.