.jpg) By Susha Cheriyedath, M.Sc.Reviewed by Skyla BailyNov 26 2021

By Susha Cheriyedath, M.Sc.Reviewed by Skyla BailyNov 26 2021An organic solar cell (OSCs) is a form of PV that uses organic electronics, a field of electronics that works with conducting biopolymers or tiny organic compounds, for light absorption and electrostatic interactions in order to generate energy via the photoelectric cell. OSCs make up the majority of natural solar cells, as stated in a new research paper posted to the chemRxiv* preprint server.

Study: Environmentally friendly and roll-processed flexible organic solar cells based on PM6:Y6. Image Credit: Thongsuk7824/Shutterstock.com

Organic Solar Cells (OSCs) are achieving higher efficiencies all the time, thanks to non-fullerene recipients that allow precise control of energy amounts and absorptivity with varied donor substances.

Photovoltaics with organic materials, when mixed with the adaptability of organic molecules, have the capability to be cost-effective for solar applications. Because organic compounds have a high optical absorption efficiency, great intensity of light may be collected with a small number of materials. In comparison to other (PV) innovations, OSCs offer appealing characteristics including low price, mechanical stability, light weight, and the ability to be semi-transparent.

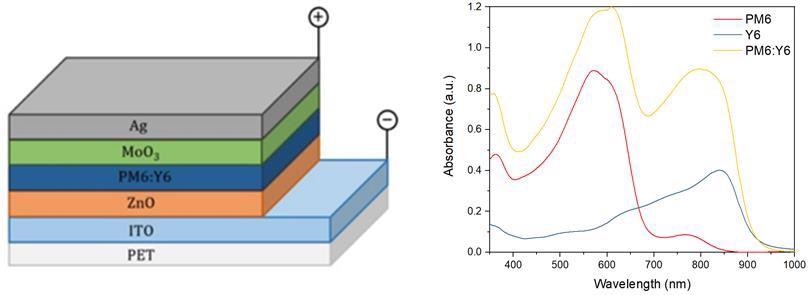

(left) Representation of the inverted OSC used for this study. (right) Absorbance of photoactive materials in O-XY (16 mg/mL) slot-die coated at 100 °C. Image Credit: Castro, M., et al, Chem Rxiv

All of this causes OSCs to be among the most attractive photovoltaic devices, attracting a huge amount of research interest in order to bring them to market. Furthermore, there is still a potential productivity difference between solar cells made with lab-scale procedures and those made with industry-compatible technologies.

Why Slot Die Coating with PM6:Y6?

Designed to be compatible with roll-to-roll production, slot-die coating, blade coating, or even aerosol coating are by far the most dependable adaptable manufacturing procedures for OSCs. Slot-die coating, on the other hand, is favored because it allows for a one-dimensional arrangement in the shape of one or even more bands with a very well-defined width and nearly no resource waste. As a result, slot die coating ought to be the preferred method for high-efficiency devices in order to help close the "lab-to-fab gap."

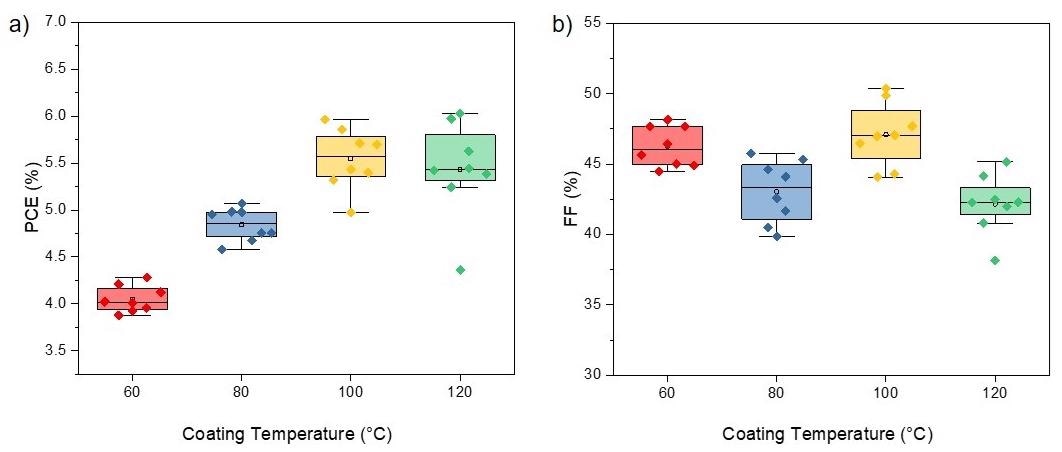

Statistic representation of the measured PV parameters of PM6:Y6 devices fabricated at different temperatures: a) Power Conversion Efficiency (PCE) and b) Fill Factor (FF). Image Credit: Castro, M., et al, Chem Rxiv

Dozens of new novel donors and acceptors, particularly PM6 donors with Y6 acceptor materials, have lately started popping up. When employing green solvents, researchers demonstrated remarkable efficiency of over 15% on stiff materials.

The absorbed PM6 accurately reflects the solar spectrum's greatest spectroscopic irradiation point, while Y6 complements this absorbance in the red section of the spectrum. As a result, the PM6:Y6 substance mixture is an excellent choice for bridging the efficiency differences between different production processes.

Manufacturing Methods

Transferring PM6:Y6 electronics to roll manufacturing on different substrates employing scalable manufacturing processes such as slot-die lamination is still required. Nevertheless, because PM6 displays temperature-dependent aggregation (TDA), it must be preheated during the slot-die coating technique to stay liquid. In this situation, the substrates, tubes, syringes, and slot-die heads are all heated throughout the coating process.

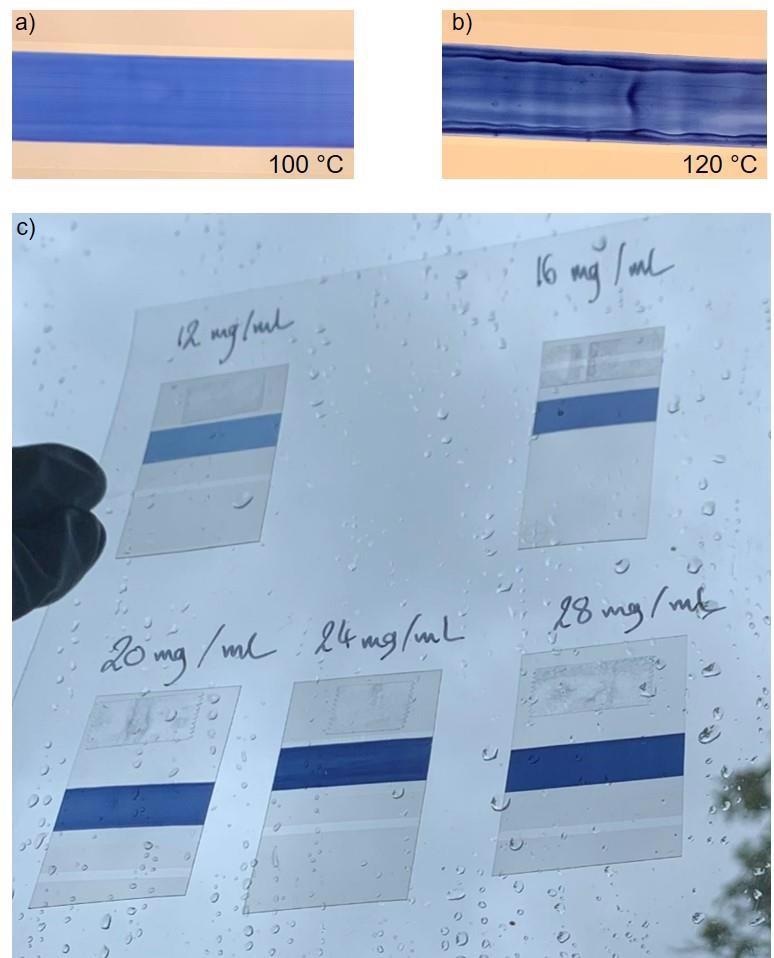

PM6:Y6 slot die coated at a) 100 °C and b) 120 °C. c) Effect of the AL thickness on the transparency of the ITO/ZnO/AL stack against a window light. Image Credit: Castro, M., et al, Chem Rxiv

The possibility of slot-die coating PM6:Y6 outdoors on composites based on a green solution without additives was proven. The improvement of coating variables is illustrated. Now, since significant efficiencies have been achieved utilizing lab-scale procedures, the results may readily be translated to a roll-to-roll platform; this is critical to boosting the profitability of this innovation.

It has recently been demonstrated that utilizing PM6:Y6 as active materials and a heated slot-die coating over an ITO-coated specimen at the same temperature as the solvent produces an efficiency of over 15%. These efficiencies were attained without using additives at a level of 16 mg/mL in the green solvents O-XY or trimethylbenzene (TMB).

At higher temperatures, the short-circuit current is increased. Whenever the temperature increased over 100 °C, the solvents dried quicker, causing substance agglomeration on both corners of the AL, horizontal to the coated direction.

The above effect causes inhomogeneities along with stripes, which has a direct effect on the finished product's efficiency. Charge transport recombination is important in determining the resulting PV characteristics because recombination implies that the electrons are lost before they reach the electrodes. The intensity of light dependency of current and open-circuit voltage may be used to analyze the degree and dominating type of recombination.

Researchers predict the recombination procedure at open-circuit voltages to gain distinct and complementary information upon recombination processes occurring in the OSCs coated at various temperatures. Increasing the thickness of the AL also has an impact on the device's efficiency.

A thick AL will boost light absorption while also making the finished product more durable, which is critical when using roll-to-roll because the process involves pressure, folding, and stretching. Thinner AL layers enable semi-transparent devices, which are appealing for a variety of applications, as well as reducing charge carrier paths, lowering the likelihood of recombination until being absorbed in the device electrodes.

Researchers applied the hot slot-die coating using a solution based on the blend's temperature aggregated behavior, determining that by synchronizing the flexible heating rate to the hot slot-die head at 100°C, they were able to achieve the desired results.

*Important Notice

ChemRxiv publishes preliminary scientific reports that are not peer-reviewed and, therefore, should not be regarded as conclusive or treated as established information.

References

Castro, M., et al. (2021). Environmentally friendly and roll-processed flexible organic solar cells based on PM6:Y6. Chem Rxiv. Nov 25, 2021 Version 3. https://chemrxiv.org/engage/chemrxiv/article-details/619f5d1b784805839a9a5940

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.