It has been predicted that the amount of lithium produced between 2015 and 2019 will need to double between 2025 and 2030 to meet electric vehicle demand. A new review presented in the Materials Proceedings journal has explored how these demands are being addressed in the Quebec area, thanks to a series of distinct factors and processes.

Study: Perspectives of Lithium Mining in Quebec, Potential and Advantages of Integration into a Local Battery Production Chain for Electric Vehicles. Image Credit: aanbetta/Shutterstock.com

The year 2020 saw the global number of electric cars on the road reach 10 million, representing a 43% increase over 2019’s figures. Battery electric vehicles were reported to account for two-thirds of new electric car registrations and two-thirds of the active stock in 2020.

As well as personal car use, electric vehicles have become increasingly viable options for applications in goods transportation, public transit, and even underground mining equipment.

The growing prevalence and popularity of electric vehicles have resulted in never-before-seen demand for the lithium carbonates used in lithium-ion batteries; a demand which continues to increase as the accessibility and applicability of electric vehicles continues to evolve and expand.

Lithium-ion batteries have long been considered to be ideal candidates for use in electric vehicle applications due to their high energy density, low self-discharge, low maintenance, and – more recently – their affordability.

One of the main challenges to the application and commercialization of lithium-ion batteries stems from the fact that lithium does not naturally exist in its metallic form. Rather, this is found in oxidized deposits including brines, seawater, minerals, and sedimentary rocks.

Commercial sources of lithium tend to be based on either brine deposits or pegmatites (hard-rock lithium minerals).

In order to access pegmatite ores, it is typically necessary to mine and process these using standard drilling and blasting approaches before transporting these to a central processing facility. Once at the processing facility, multiple stages of crushing and grinding are used to liberate the minerals from gangue, often via dense media separation.

In order to extract lithium from brine deposits, the naturally occurring solution must be pumped into ponds to allow solar evaporation to take place. This process concentrates the dissolved lithium salts by moving it through a series of ponds of increasing concentration before precipitating the product.

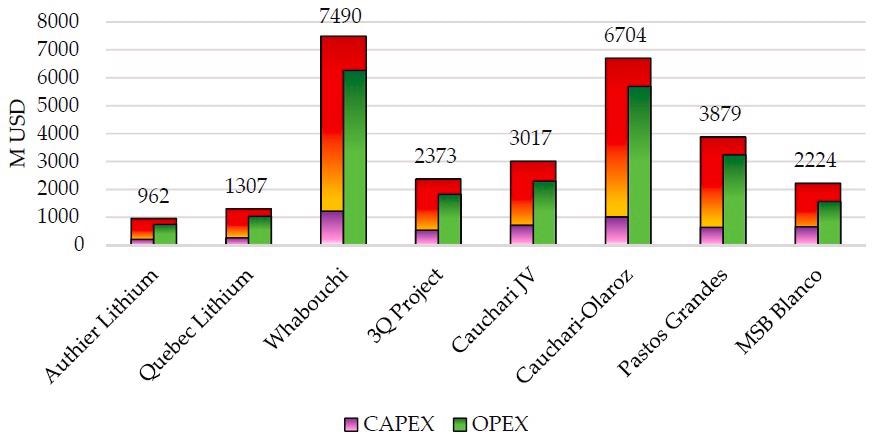

Figure 1. CAPEX and OPEX over the life of mine from the analyzed lithium mining projects (the red bar represents the sum of the CAPEX and OPEX).

More recently, conventional pegmatite projects have become considered to be economically viable alternatives to historically more cost-effective brine sourcing methods. This is particularly notable in the Canadian province of Quebec, which is home to some of the most important pegmatite-based lithium mineral reserves in the country.

Quebec’s existing mining ecosystem offers the potential to integrate lithium production into an entirely local added value chain, but this potential is currently hindered by technical and technological challenges.

In order to explore this potential and its related barriers, the paper’s authors opted to analyze the province’s battery production capacity and linked greenhouse gas emissions, comparing projected economic factors for local Quebec-based pegmatite projects with brine projects in other countries to evaluate whether or not these could be equally as viable.

The authors highlighted that their primary goal was to identify the economic potential and other advantages of lithium mining in Quebec, with a view to integrating the process’s final products into a local battery production chain aimed specifically at the electric vehicle market.

One of the first considerations identified was that current brine processing projects are typically much larger than Quebec’s hard-rock mining projects. This is the case in terms of their net present value, mine (or process) life, and capital costs involved in their operation. For example, four of the region’s five mines have a working life of over 30 years, while the brine-based operation investigated tended to operate for 14-15 years.

The authors’ comparison revealed that the net present value of the lithium mining projects from pegmatites in Quebec was far lower than the investigated lithium mining projects from brines. The Quebec-based projects also offered a consistent internal rate of return of between 30% and 34%, while the investigated brine projects revealed a greater variability between 24% and 61%.

It was noted that while the Quebec-based mining projects involved lower capital costs, these also offered a more moderate net present value. They were not the most competitive option of those investigated in terms of overall production costs, but optimizations and improvements around process control, unit metal recovery, and energy usage could help lower these costs.

Another key consideration in the advancement of any industrial or mining operation lies in its greenhouse gas emissions. The production of lithium-ion batteries in Quebec is expected to emit 1.9 metric tons of equivalent CO2 during the production stage, though this estimate only incorporates energy requirements for lithium extraction itself and not the surrounding processes.

It has been estimated that the production and assembly of 10 to 21 million lithium-ion batteries destined for use in electric vehicles would produce between 3.80 and 5.34 metric tons of equivalent CO2.

It should be noted that the entire fleet of personal internal combustion engine vehicles in Quebec emits around 17.1 metric tons of equivalent CO2 per year. The option to replace these with locally-sourced electric vehicles is, therefore, an appealing prospect.

A number of highly localized factors help to make this process more environmentally friendly, including the availability of affordable hydropower and the option to use established public infrastructures such as power lines, highways, and water supplies. There is also a qualified local workforce with considerable historic mining expertise available.

While market factors tend to remain the key drivers for projects such as the lithium mining projects outlined here, the authors believe that this project remains significantly appealing on an environmental basis. They hope to explore the project’s competitiveness and profitability as part of future work in order to present a more robust business case for this approach.

References

Ibarra-Gutiérrez, Sebastián, Jocelyn Bouchard, Marcel Laflamme, and Konstantinos Fytas. 2021. "Perspectives of Lithium Mining in Quebec, Potential and Advantages of Integration into a Local Battery Production Chain for Electric Vehicles" Materials Proceedings 5, no. 1: 33. https://www.mdpi.com/2673-4605/5/1/33

International Energy Agency (2021), Global EV Outlook 2021, IEA, Paris https://www.iea.org/reports/global-ev-outlook-2021

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.