A novel study published in Diamond and Related Materials is focused on a novel technique that utilizes fast combustion to synthesize carbon nanostructures. A simple technique for the rapid and autothermal creation of several forms of nanocarbon, including a 3D graphene-like nanosystem, has been demonstrated using combustion formulation.

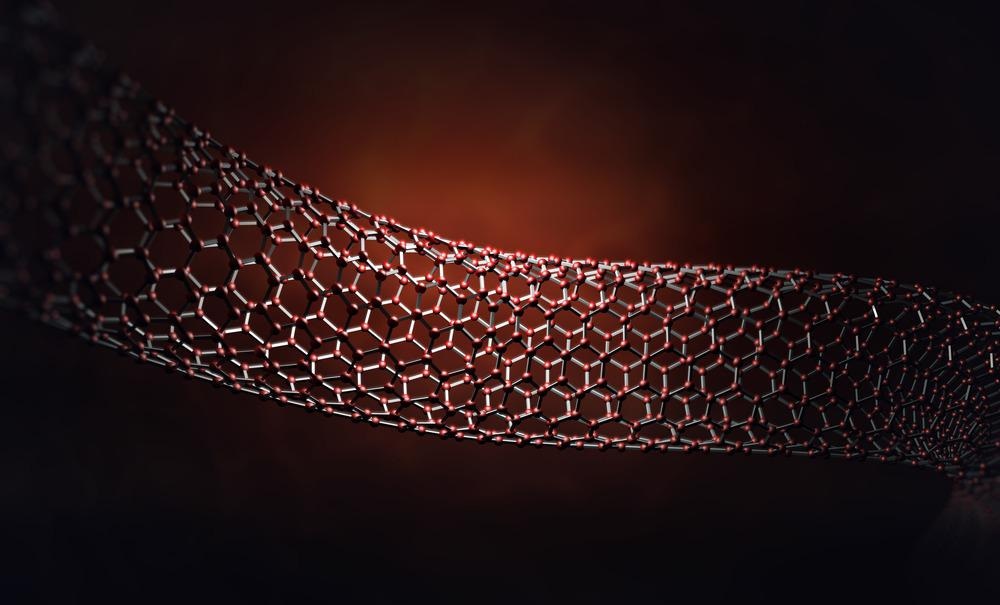

Study: Novel nanocarbons via facile one-pot combustion synthesis. Image Credit: Mopic/Shutterstock.com

Importance of Carbon Nanostructures

The research shows that advances in nanotechnologies have spurred the development of novel materials such as graphene, carbon nanotubes, and fullerenes in the last few years.

Carbon nanostructures have been hailed as one of the most intriguing reinforcing materials for improving the characteristics of polymeric substances due to their exceptional structural rigidity, high conductivity, and electromagnetic attributes.

Carbon nanostructures are a diverse range of materials with applications in biomedical and biotechnology, tissue engineering implants, biosensing, and enhanced functional genomics. Because of their unique characteristics and various prospective uses in the automobile, aerospace, architectural, and electrical sectors, carbon nanocomposites, and polymers have piqued attention.

Carbon Nanostructure Synthesis Processes and Limitations

Several synthesis techniques have been carefully explored in the fast-evolving subject of nanotechnology. Nanomaterials are presently produced in a variety of ways, all of which are regarded to be difficult and costly. This encourages individuals to look for new ways to synthesize them.

The 'bottom up' strategy, which is widely employed, involves self-assembling structural components to produce new nanoparticles. Thermal activation, ionized synthesis, gaseous phase condensation, blasting, and milling are just a few of the methods used. Due to labor-intensive, time-consuming, and energy-intensive protocols, many of these procedures are neither financially viable nor productive. As a result, different approaches should be explored to address the present flaws.

Combustion Synthesis

For the establishment of efficient energy and time-saving nanotechnological synthesis, solid combustion synthesis (CS) can be used. By appropriate choice of beginning reagents, the self-sustaining reaction between a powerful reduction agent and a robust oxidant can result in the creation of various nanostructures.

Further Reading: Rheology of Graphene and Carbon Nanotube-Enhanced PLA

It is ecologically friendly and beneficial from an energy standpoint because it is self-sustaining. Furthermore, the comparatively fast reaction time limits the creation of undesirable phases, allowing for time savings and financial gains. The major benefits of this approach are linked to its unique qualities. Excellent reaction temperatures (more than 3000 K) and pressure changes, which are hard to obtain with traditional procedures, and lead to a wide range of materials with high purity.

Limitations of Carbon Synthesis

The use of quick, self-sustaining exothermic processes, which make the combustion approach relatively easy, highly efficient, and time conserving, makes CS under controlled settings extremely challenging. It necessitates continuous and rapid assessment since even minor differences might render the output unusable.

A sustainable, clean strategy for the quick fabrication of carbon material nanostructures utilizing the CS approach is presented in the recently published research.

Effective Utilization of Reagents/Materials

Magnesium is a relatively inexpensive, powerful, and conveniently removable reactive. As a result, it was utilized as a reductant. As oxidizing agents, both carbon-bearing chemical reagents and everyday consumer items were utilized.

Novel Inexpensive Experimental Setup

The reaction took place in a stainless-steel highly pressurized tank. An agate crusher was used to homogenize a greenish stoichiometric combination of granular (below 40 m) reagents, which were then put into a silicon furnace and put inside a reactor vessel.

The vessel was sealed firmly, emptied, then filled with Ar at a precise pressure (1.0 and 0.1 MPa). The combustion process was started by a carbon fiber (used as an electrical igniter) that was immersed within the green sample.

Experimental Findings

Depending on the system, the overall reaction time ranged from 1.93 s to >2.3 s (>2.3 s, 2.03 s, 2.13 s, 1.93 s for A, B, C, and D, respectively). For A, B, C, and D, the greatest combustion intensity was recorded at 0.2 s, 0.066 s, 0.33 s, and 1.4 s, respectively.

The refined result of phthalic acid burning (runs A) was characterized by a perforated petal-like multi-layered graphene substance that resembled 3D graphene-based nanocarbon. Glucose combustion (runs B) resulted in the transformation of the inhomogeneous mixture into MgO nanocrystallites. The sucrose combustion results were nearly identical to glucose combustion and resulted in MgO nanoparticles as well as soot production.

Because certain MgO nanocrystallites were securely coated by graphene multi-layers during the sugar combustion, the oxide core could not be degraded during filtering.

In short, the carbon-based nanomaterials were efficiently and effectively synthesized by the utilization of the autothermal CS process resulting in the formation of layered nanomaterials with excellent properties. This process paves the way for various future perspectives and novel applications for the benefit of humans.

References

Huczk, A. et al., 2022. Novel nanocarbons via facile one-pot combustion synthesis. Diamond and Related Materials, Volume 121. 108746. Available at: https://www.sciencedirect.com/science/article/pii/S0925963521005094?via%3Dihub

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.