Scientists from Tokyo Tech, AIST and Yamagata University launch a novel strategy to reestablish the low electrical resistance of all-solid-state batteries, thereby pushing them a step closer to becoming the powerhouse of advanced electronics.

Image Credit: Shigeru Kobayashi and Taro Hitosugi of Tokyo Institute of Technology.

The scientists also analyze the fundamental reduction mechanism, opening the door for a more important understanding of the functioning of all-solid-state lithium batteries.

All-solid-state lithium batteries have become a new trend in materials science and engineering as conventional lithium-ion batteries are unable to meet the standards for advanced technologies, such as electric vehicles, which require rapid charging, high energy densities and long cycle lives.

All-solid-state batteries, which utilize a solid electrolyte rather than a liquid electrolyte present in traditional batteries, not only meet these criteria but are relatively safer and more convenient as they have the potential to charge in lesser time.

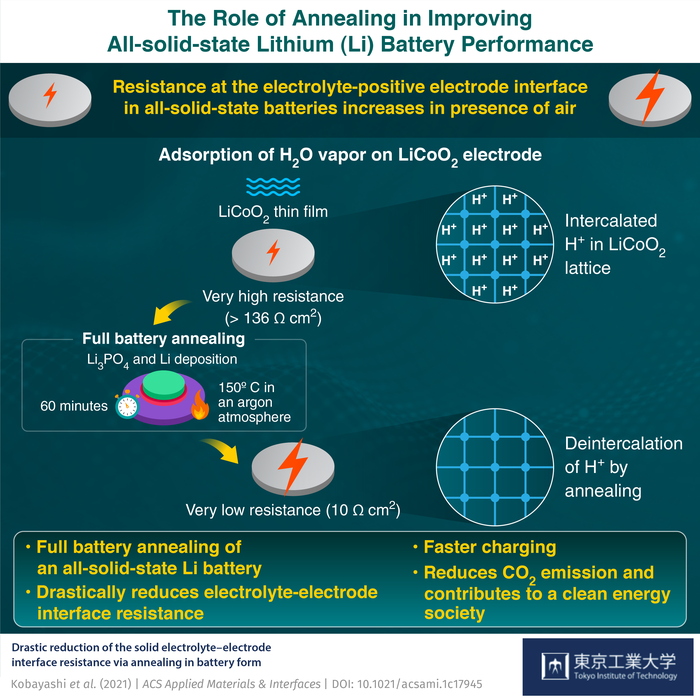

However, the solid electrolyte has its own challenge. The interface between the positive electrode and solid electrolyte exhibits a large electrical resistance whose source is not properly understood.

Additionally, the resistance grows when air touches the electrode surface, lowering the battery performance and capacity. While numerous attempts have been carried out to lower the resistance, none have succeeded in bringing it down to 10 Ω cm2, the stated interface resistance value when not exposed to air.

Currently, in a study published in the journal ACS Applied Materials & Interfaces, a research team guided by Prof. Taro Hitosugi from Tokyo Institute of Technology (Tokyo Tech), Japan, and Shigeru Kobayashi, a doctoral student at Tokyo Tech, may have finally found a solution to this problem.

By launching a strategy for reestablishing the low interface resistance as well as discovering the mechanism behind this reduction, the team has offered critical insights into the development of high-performance all-solid-state batteries.

The study was the outcome of collaborative research among Tokyo Tech, the National Institute of Advanced Industrial Science and Technology (AIST), and Yamagata University.

To begin, the team prepared thin-film batteries containing a LiCoO2 positive electrode, a lithium negative electrode and a Li3PO4 solid electrolyte. Before finishing the production of a battery, the researchers uncovered the LiCoO2 surface to air, hydrogen (H2), oxygen (O2), nitrogen (N2), carbon dioxide (CO2) and water vapor (H2O) for 30 minutes.

To their astonishment, they learned that exposure to O2, N2, CO2 and H2, did not lower the performance of the battery compared to a non-exposed battery.

Only H2O vapor strongly degrades the Li3PO4 – LiCoO2 interface and increases its resistance drastically to a value more than 10 times higher than that of the unexposed interface.

Prof. Taro Hitosugi, Study Lead, Tokyo Institute of Technology

Next, the team carried out a process known as “annealing”, wherein the sample endured a heat treatment at 150 °C for an hour in battery form i.e., with the negative electrode deposited. Remarkably, this decreased the resistance down to 10.3 Ω cm2, similar to that of the unexposed battery.

By carrying out numerical simulations and innovative measurements, the researchers then showed that the reduction could be linked to the spontaneous elimination of protons from within the LiCoO2 structure during the annealing process.

Our study shows that protons in the LiCoO2 structure play an important role in the recovery process. We hope that the elucidation of these interfacial microscopic processes would help widen the application potential of all-solid-state batteries.

Prof. Taro Hitosugi, Study Lead, Tokyo Institute of Technology

Journal Reference:

Kobayashi, S., et al. (2022) Drastic reduction of the solid electrolyte–electrode interface resistance via annealing in battery form. ACS Applied Materials & Interfaces. doi.org/10.1021/acsami.1c17945.