In a recent study published in the open-access journal Frontiers in Energy Research, researchers from China reviewed various factors affecting the practical applicability of lithium (Li) in the anode of a Li-ion battery (LIB).

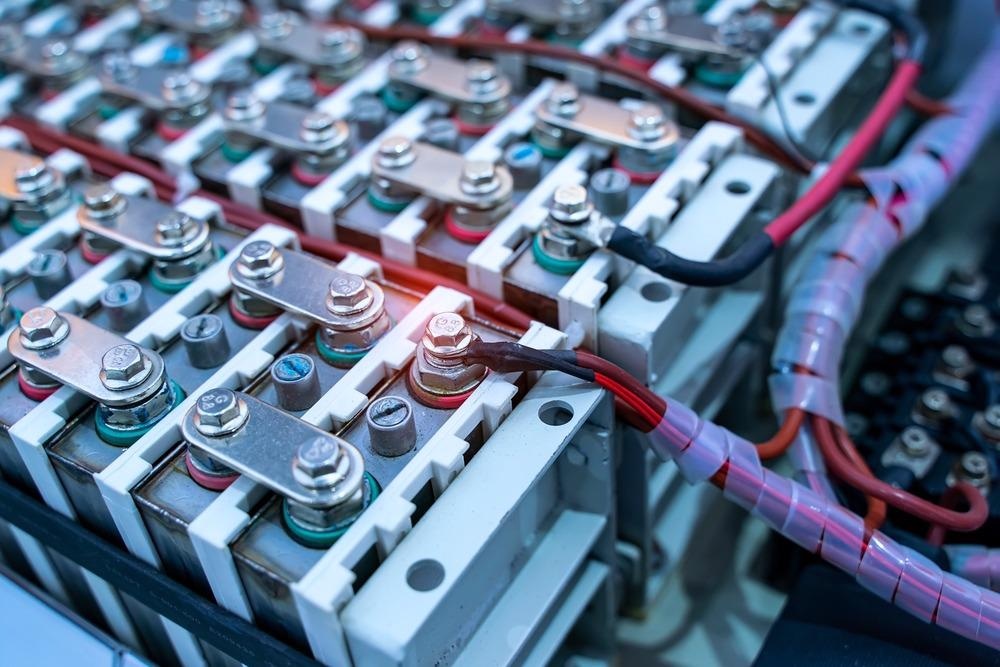

Study: Controlled Lithium Deposition. Image Credit: asharkyu/Shutterstock.com

This review primarily focuses on current advancements in the selection, structural design, and morphology of current collectors to suppress the uncontrolled growth of Li dendrites that causes short-circuit and accommodate large volume change of the electrodes during cyclic plating and striping.

The design of the current collector for controlled Li deposition had three aspects, namely deposition on micro-nano structures, lithium deposition in carbon nanotubes (CNT), and selective deposition promoted by alloys with high Li affinity (lithiophilic).

Use of Li in the Anode of LIBs

A typical LIB consists of four components: a cathode, electrolyte, anode, and separator. In the case of the most commonly used LIB configuration, the cathode is Li-based; however, as Li is highly volatile, the cathode is usually made up of Li cobalt oxide.

Similarly, the anode is usually based on graphite (C) or silicon (Si). Graphite acts as the host of Li-ion during intercalation /deintercalation, i.e. charging/discharging. However, Li-based anodes are also a viable option due to low redox potential and high theoretical capacity, especially for Li-sulfur (Li-S), Li-oxygen (O2) (Li-O2), and solid-state LIBs (i.e., no electrolytes).

The major issues with Li-based anodes are the uncontrolled growth of Li dendrites, which promotes side reactions and impales the separator to cause a short-circuit. The key aspects of a promising solution for this are to control the Li nucleation location, Li dendrite growth direction, and the surface morphology of the deposited Li. Moreover, the controlled deposition of Li metal can be realized by designing the current collectors (CCs), optimizing the electrolyte, using solid electrolytes, and creating artificial solid electrolyte interface (SEI) layers.

The conventional liquid electrolyte can be replaced with solid electrolytes with enhanced mechanical properties or gel electrolytes with high ion conductivity. Similarly, to inhibit Li dendrite growth and form a stable SEI layer, several additives can be added to the electrolyte viz. LiNO3 and vinylene carbonate (VC). To inhibit the side reaction, many organic and inorganic compounds can be incorporated into the anode. These are LiF, Li3N, Al2O3, and poly (vinylidene difluoride) (PVDF).

Current Advancements in the Designing of CCs

Porous CCs can inhibit the uncontrolled growth of the Li dendrites due to the following reasons. Their uneven surface morphology can be used to regulate the distribution of the electric field along with the interface of the CC and electrolyte, and the local current density can be regulated by controlling the Li-ion concentration gradient from the surface towards the depths of pores.

Hence, proper control over micro and nanopores on the CC is crucial. Additionally, Li itself can have a porous structure to facilitate controlled deposition. 3D porous CCs are also potential candidates. The protuberant tips of copper (Cu) nanofibers in a 3D Cu foil can serve as nucleation sites. In addition to Cu foils, titanium (Ti), nickel (Ni), C, and their composite shells have also shown promising results.

The lithiophilic materials reduce the nucleation barrier potential for the heterogeneous nucleation of lithium, which increases the energy conversion efficiency of the CC. They serve two purposes. Firstly, the polar functional groups on their surface attract Li-ion and secondly, the reactive substrates electrochemically react with Li enhancing the Li plating rate. The C-based reactive substrates form LixC6, whereas metal or nonmetal-based substrates form LiX on the metal compounds. Some of these reactive metal substrates are ZnO, CuO, CuF2, NiF2, Cu3P, and CuN.

Furthermore, polar functional groups such as –NH and –C=O exhibit higher binding energy to Li-ion than Cu and Li itself. Thus, they absorb a significant amount of Li-ion, which reduces electrostatic interaction between protrusions of CC and Li-ion. However, the content of polar functional groups and lithiophilic metal oxides should be optimized to prevent poor electronic conductivity of the CC. Another option is to use CNT sponges, silver-plated carbon fiber paper, or CNT cavities for Li deposition. They can alleviate the issue of poor electronic conductivity associated with lithiophilic metal oxides.

Conclusions

To conclude, the researchers presented a review of current scientific advancement in controlled Li deposition on the CC/anode of a LIB. The effective control of Li intercalation/ deintercalation on graphite and silicone CC or Li plating/stripping on metal and nonmetal CC is the most critical factor to inhibit uncontrolled growth of Li dendrites and prevent side electrostatic reactions.

Lithiophilic metal oxides, CNT-based composites, and materials with polar functional groups with 3D porous micro/nanostructure are currently the best feasible solutions for this.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Zhang, S., Yang., G., Li, X., Li, Y., Wang, Z., Chen, L., Controlled Lithium Deposition, Frontiers in Energy Research, 2022, 10, 837071. https://www.frontiersin.org/articles/10.3389/fenrg.2022.837071/full