By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Feb 22 2022

By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Feb 22 2022In an article recently published in the open-access journal Materials, the researchers reported the development of ambient-dried silica aerogel powders derived from coal gangue using a one-pot method.

Study: Ambient-Dried Silica Aerogel Powders Derived from Coal Gangue by Using One-Pot Method. Image Credit: Parilov/Shutterstock.com

Background

Silica aerogel is an amorphous/non-crystalline material with many advantageous features which is generated via nanoparticle aggregation using air as a dispersing medium. Many synthetic routes for silica aerogels have been developed so far. However, there are several drawbacks to these methods, such as intricate processing, excessive costs, and safety concerns.

Despite the advancement of ambient pressure drying, the high cost of precursor materials and the complexity of surface chemical modification procedures continue to hinder large-scale industrial manufacturing. To overcome these drawbacks, it is evident that the gels must be made from a less expensive silicon precursor, modified using a simplified technique, and dried at room temperature.

Coal gangue is a low-carbon, grey, or black rock rich in silica and alumina. To increase the added value of coal gangue, a variety of application methods have been developed. However, coal gangue utilization is still below 15% and is mostly focused on its usage as a building material. As a result, it is advantageous to design a novel and effective approach to broaden its potential applications in the field of coal gangue resource recovery.

Because coal gangue is rich in silicon, it has been employed as a cheap silicon precursor in recent studies to synthesize silica compounds. The development of a viable path for the preparation of high-performance materials, such as silica aerogels and their corresponding composite materials, has been a current topic of research. These materials can be generated by recycling this low-cost and environmentally linked huge stored solid waste.

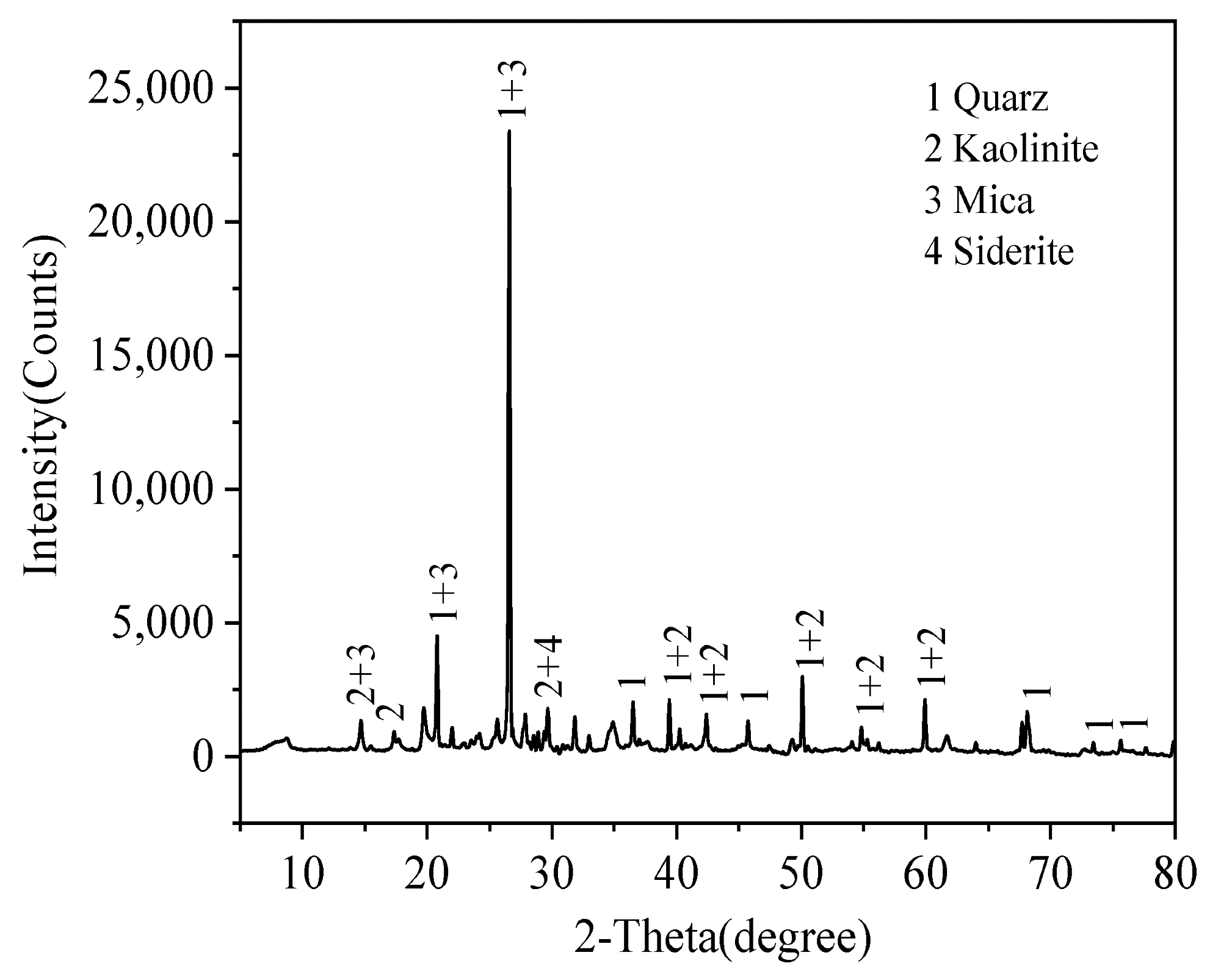

XRD pattern of coal gangue materials. Image Credit: Wei, J et al., Materials

About the Study

In the present study, the authors presented a new and simple approach for the synthesis of insulating aerogels from solid waste coal gangue, which could lower the cost of industrial silica aerogel production and could simultaneously achieve high value-added usage of solid waste.

As a precursor for silica aerogels, sodium silicate was prepared from a cheap industrial waste coal gangue, which was used in a one-pot method for silica wet gel preparation. This method of solvent exchange/surface modification was carried out quickly by mechanical stirring, and the wet gels derived from coal gangue were dried at ambient pressure. For suitable ambient pressure drying, the silica surface was changed using hexamethyldisilazane (HMDS) and heptane. Under normal pressure, the surface of silica was successfully dried, and energy consumption was lowered.

Furthermore, the potential of similar procedures for creating nanomaterials such as SiO2 aerogel, silica, and SiO2-Al2O3 aerogel was elucidated towards the successful extraction of silicon from coal gangue, allowing for effective use of coal gangue. This work demonstrated a cost-effective method for synthesizing silica aerogel powder using recycled solid waste materials, lowering aerogel production costs, and maximizing the value of coal gangue waste.

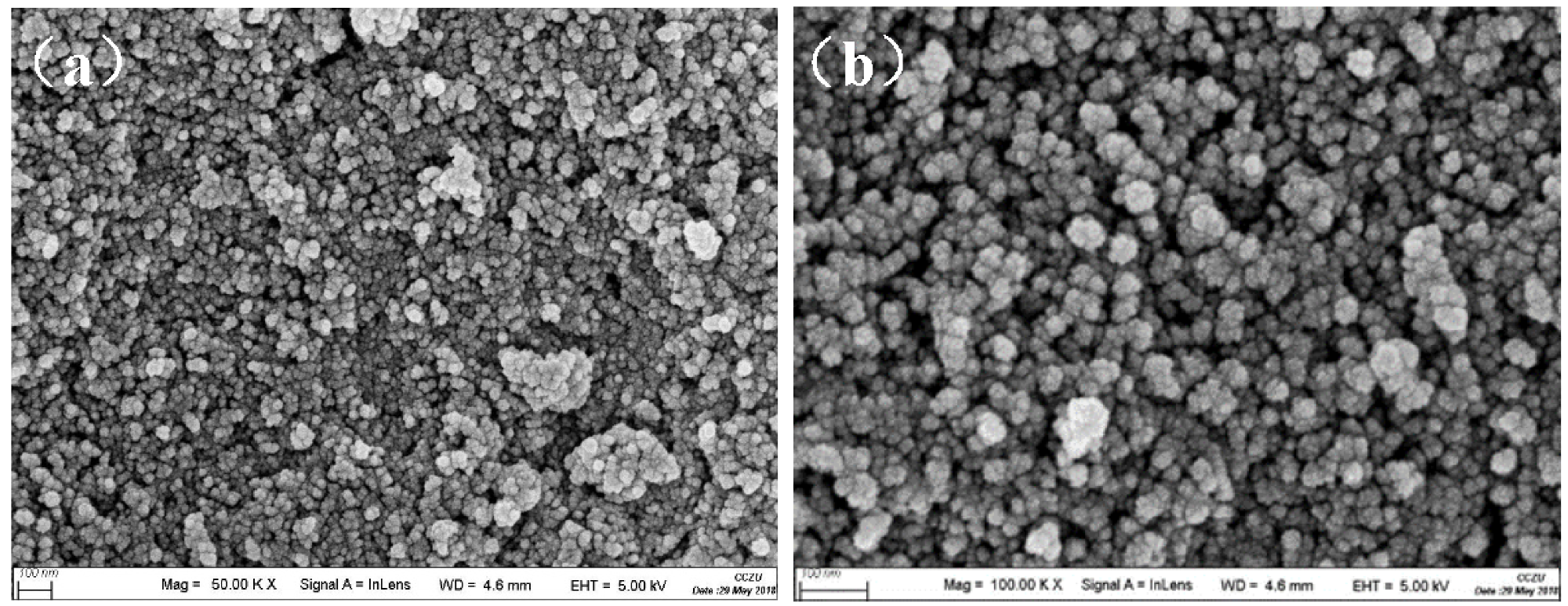

SEM image of silica aerogel powders at (a) 50.00 KX and (b) 100.00 KX magnification. Image Credit: Wei, J et al., Materials

Observations

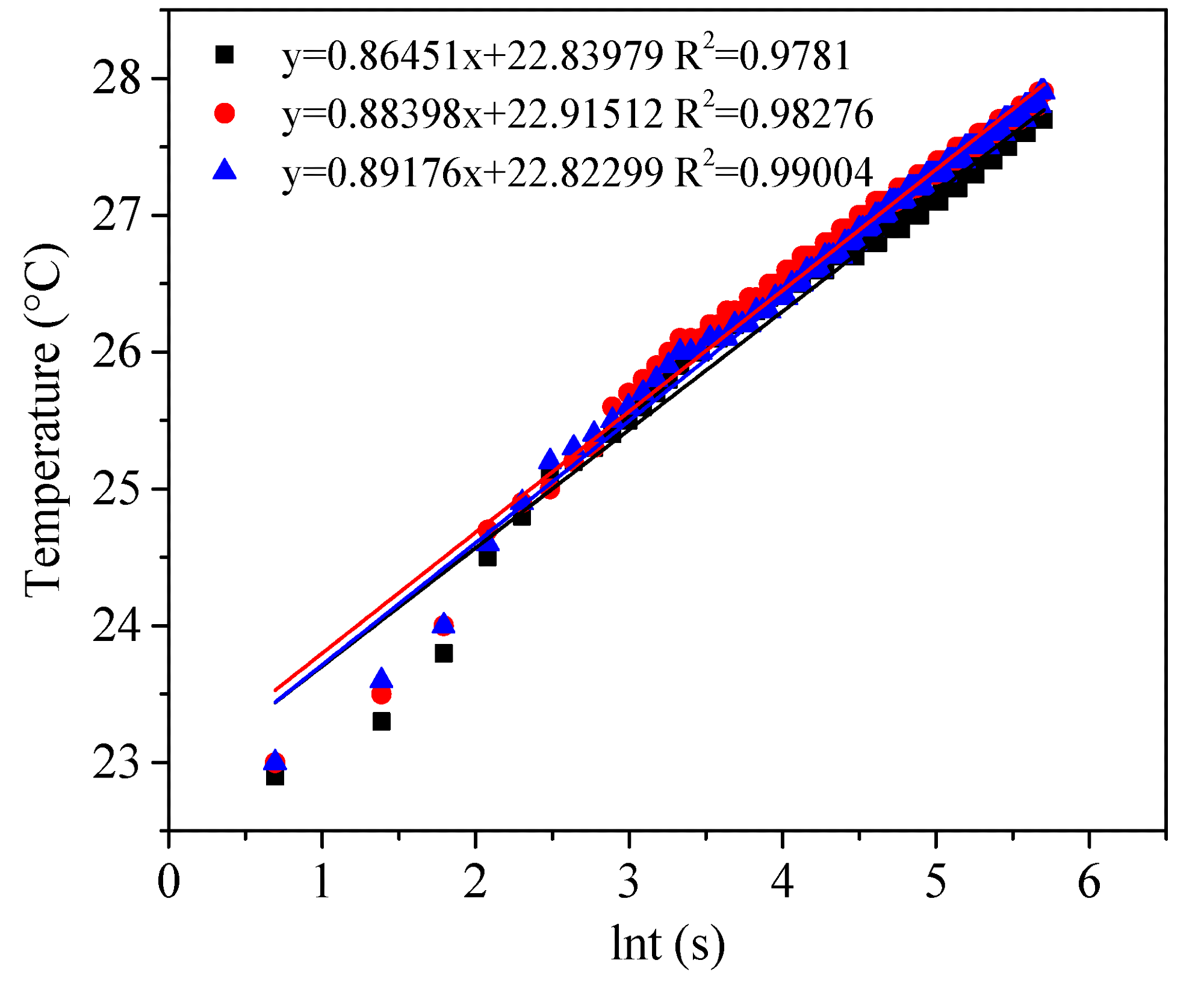

In this study, the researchers observed that the developed nanostructured aerogel had a high surface area of about 748 m2/g with a 3D open porous microstructure that had a low density of approximately 0.18 g/cm3 and excellent thermal insulation performance, with a thermal conductance value of 0.033 W.m-1.k-1. Furthermore, it was discovered that by reusing coal gangue, the synthetic yield of silica aerogel powder reached up to 92%.

It was also determined that these properties were consistent with those reported in the literature for aerogels prepared with a typical tetraethyl orthosilicate (TEOS) precursor. SiO2 aerogels were used to absorb contaminants in water and dangerous gases in the air.

Furthermore, the ethanol, HMDS, and H2SO4 dosages were changed based on the experimental results. It was also observed that the impact of various parameters on the structure and properties of the generated aerogels needs to be further investigated.

Evaluation of thermal conductivities of aerogel powder by transient hot-wire method. Image Credit: Wei, J et al., Materials

Conclusions

In conclusion, this study elucidated the preparation of SiO2 aerogel powders by recycling solid waste coal gangue using a one-pot process. The researchers also highlighted that the aerogel powder prepared by the method described in this study had a low density (0.18 g/cm3), a large specific surface area (above 700 m2/g), a high porosity (above 90%), and good insulation (0.033 W.m-1.K-1).

Overall, this work demonstrated a practical and cost-effective path to prepare thermally insulating silica aerogel powders from recovered coal gangue solid waste. The authors believe that this method will provide insights into a cost-cutting and process-simplification process for silica aerogel powder manufacturing in industries.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Wei, J., Zhu, P., Sun, H., Ambient-Dried Silica Aerogel Powders Derived from Coal Gangue by Using One-Pot Method. Materials 15(4), 1454 (2022). https://www.mdpi.com/1996-1944/15/4/1454