By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Apr 25 2022

By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Apr 25 2022In an article recently published in the journal ACS Applied Energy Materials, researchers discussed the utility of fiber optic sensors for sodium plating detection in sodium-ion batteries.

Study: Fiber Optic Sensors for Detection of Sodium Plating in Sodium-Ion Batteries. Image Credit: gcarnero/Shutterstock.com

Background

The use of sodium-ion batteries is gaining pace in the battery industry. The accessibility of low cost, resources, and environmentally friendly nature of the majority of the sodium-ion battery chemistries are without a doubt the most important factors driving this uptick. Numerous research projects to find alternate anode materials for sodium-ion batteries have been launched.

Despite the fact that many alternatives such as bismuth, tin, and phosphorus are tested with promising results, hard carbon remains the standard material of choice. While these hard carbon qualities are beneficial, the low intercalation potential increases the likelihood of salt plating during charge.

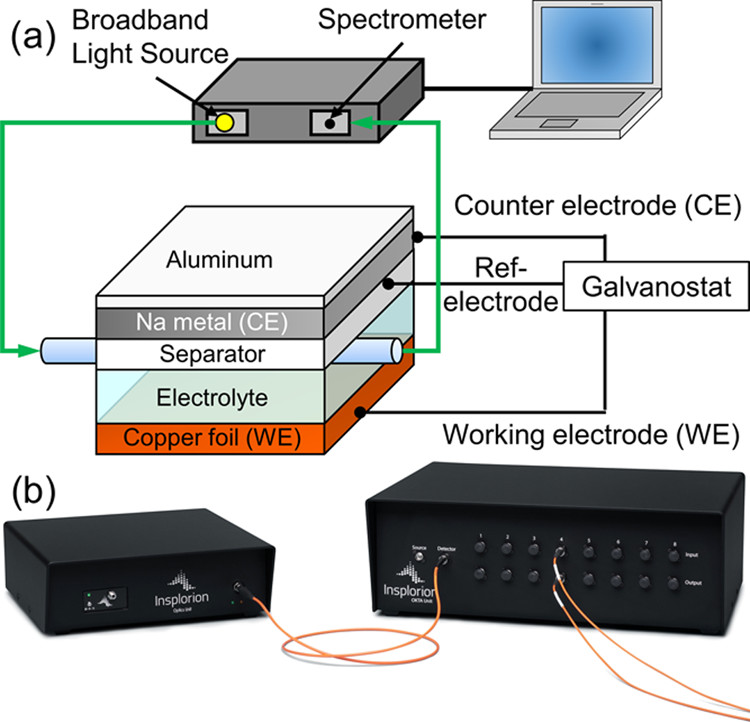

Schematic view of the optical–electrochemical setup with the FOEW sensor placed on the surface of a copper electrode in a copper–sodium half cell is shown in (a). Image of the optical unit is shown in (b). Image Credit: Hedman, J et al., ACS Applied Energy Materials

To avoid accelerated degradation and the potential of short-circuiting by dendrites, it is critical to detect plating in cells. Slow cycling of the sodium half cells or three-electrode cells, which facilitate a suitable observation of the anode potential, have traditionally been used to detect plating.

Online monitoring is possible with electrochemical methods based on differential capacity or voltage analysis in two-electrode cells, but they need extremely precise and accurate measurements, and plating is detected indirectly from the discharge profile. It would be possible to interrupt charging or reduce current to avoid cell failure by developing a fiber optic sensor that reliably identifies plating before any substantial amount of sodium is deposited.

About the Study

In this study, the authors discussed the utility of operando fiber-optic evanescent wave (FOEW) spectroscopy to immediately detect sodium metal plating in electrochemical cells. Measurements with FOEW sensors on bare copper substrates and hard carbon anodes during operation in half-and full-cell configurations and those of plating on hard carbon during sodiation at various rates were demonstrated.

The team showed that FOEW sensors could detect sodium metal deposition on both hard carbon electrodes and copper foil. Plating was discovered in hard carbon as a result of insufficient intercalation sites i.e., anodes with faded capacity or poorly balanced cells as well as polarization-induced plating. The studies were conducted using the commercially available electrodes in cell designs that remained the same for the addition of a 125 μm optical fiber between the separator and hard carbon electrode.

The researchers integrated FOEW sensors into pouch cells by splicing two standard and step-index multimode optical fibers with a core diameter of 105.5 μm and a cladding diameter of 125 μm to every end of a core-less optical fiber having a diameter of 125 μm. All electrochemical studies were conducted in three-electrode pouch cells with integrated FOEW sensors in half- or full-cell configurations.

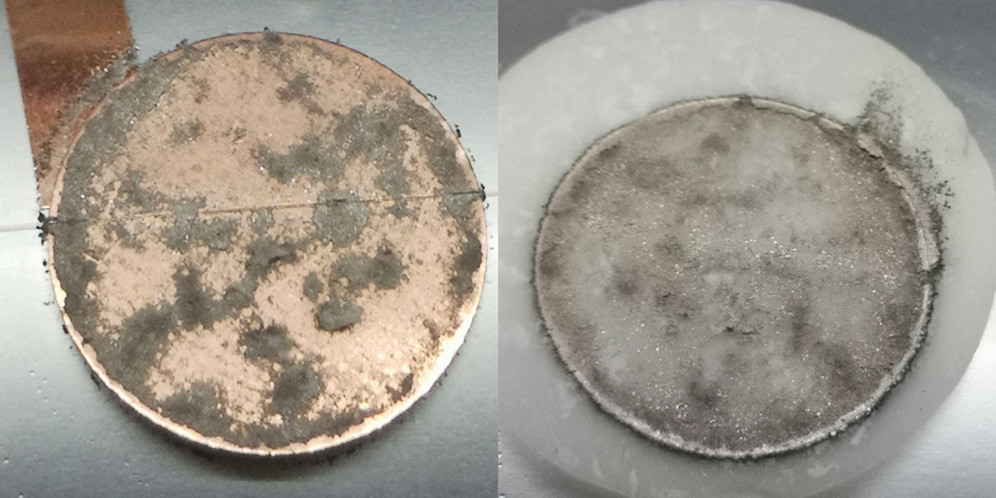

Copper working electrode after the plating experiment showing the fiber optic sensor, mossy metallic sodium, and traces of attached glass-fiber separator (left). Glass-fiber separator with the surface that was facing the copper working electrode showing that metallic sodium infiltrated the separator (right). Image Credit: Hedman, J et al., ACS Applied Energy Materials

Observations

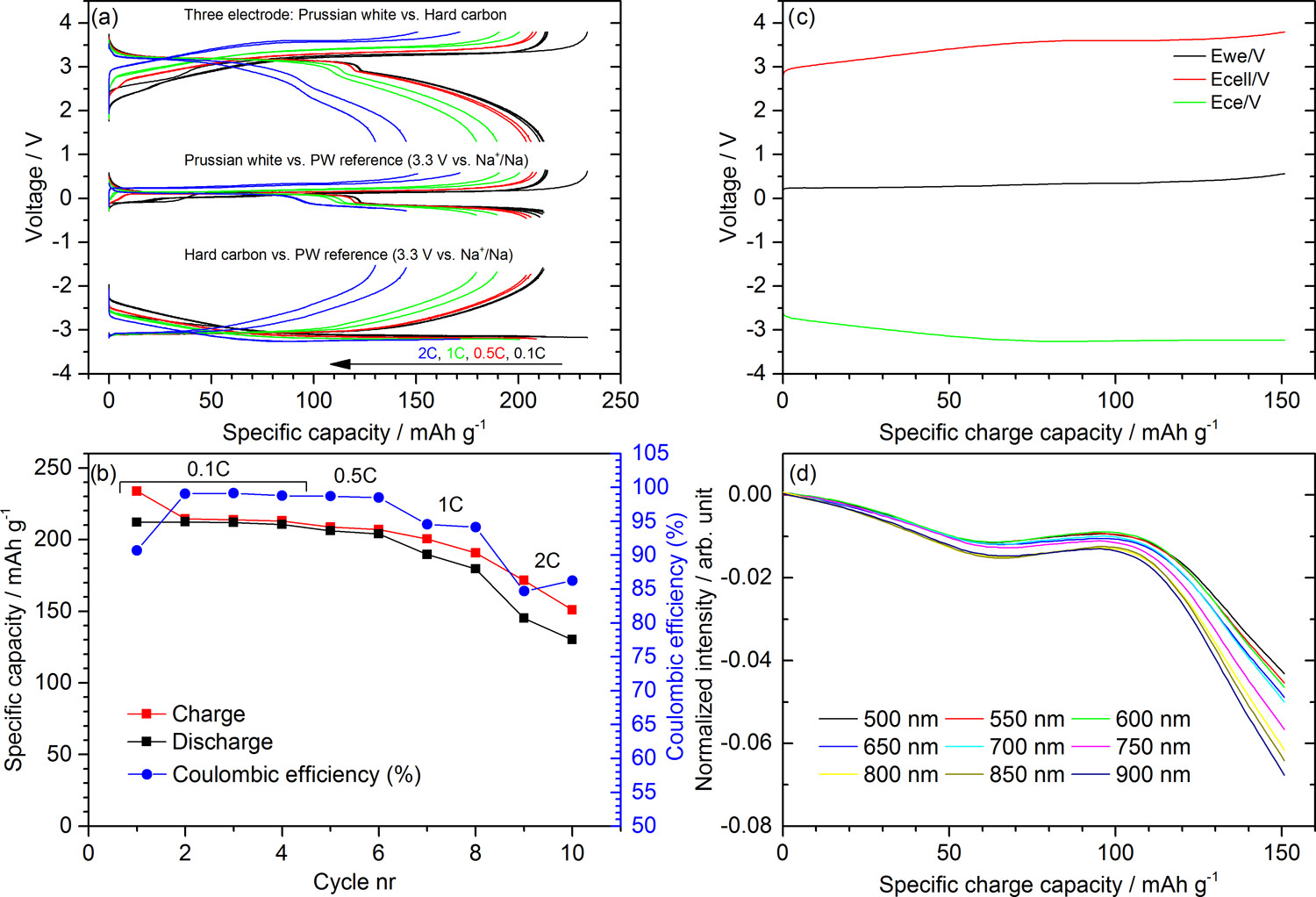

The cathodes had an aerial capacity of around 1.87 mAh cm-2. During formation at 0.1C, the first Coulombic efficiency reached 90.72%. After about 60 mAh g-1, the working electrode's potential decreased below zero. With prolonged plating, the drop in intensity of all wavelengths started to subside at 580 mAh g-1, which resembled the onset of the saturated zone seen while plating on copper, which appeared after 1520 hours. When a current of around -0.118 mA cm-2 was used to decrease sodium ions, an isolated response at wavelengths between 850 and 900 nm was observed, which gradually increased in intensity with wavelength.

Full cells with high areal capacities of >1.5 mAh cm-2 and integrated FOEW sensors cycled well in pouch cells which employed Prussian white cathodes and hard carbon anodes.

There was a distinct change in intensity at the onset of plating, and because the detection was done directly on the anode surface, it provided additional information on the sodium intercalation and plating mechanism of hard carbon. Furthermore, the sensors could be installed in conventional pouch cells without interfering with cycling, and both low and high rates of plating could be observed.

Prussian white (WE) vs hard carbon (CE) three-electrode full cell with desodiated Prussian white as the reference electrode. The voltages during constant current cycling at different rates are shown in (a) and the capacity and Coulombic efficiency are shown in (b). Voltage profiles for the last sodiation at 2C are presented in (c). The corresponding intensity output monitored in real-time at wavelengths ranging from 500 to 900 nm is shown in (d). Image Credit: Hedman, J et al., ACS Applied Energy Materials

Conclusions

In conclusion, this study elucidated that fiber optic sensors can be employed for direct operando detection of sodium-metal plating in a variety of cell topologies. It was revealed that employing the sensor does not significantly impair the cycling performance of full cells, as well as the practicality of detecting plating during fast charging of full cells.

Although hard carbon showed a weak optical signal shift during desodiation and sodiation compared to other anodes such as graphite, the information collected from the sensors can be used not only to detect plating but also to yield information about the anode material.

The authors emphasized that a simple analysis method that can provide direct feedback to the battery management system (BMS) to pause unsafe charge operations could allow battery users to operate closer to their systems' limits with fewer hazards, resulting in safer and longer-lasting batteries.

They also believe that the conclusions and experimental methodologies developed in this study should be applicable to various battery systems, such as lithium plating on graphite or the evaluation of anode-free batteries.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Hedman, J., Mogensen, R., Younesi, R., et al. Fiber Optic Sensors for Detection of Sodium Plating in Sodium-Ion Batteries. ACS Applied Energy Materials (2022). https://pubs.acs.org/doi/10.1021/acsaem.2c00595