Reviewed by Alex SmithApr 26 2022

There is a need for an energy-dense battery system in society, and as a battery with high energy density, lithium metal batteries have drawn a great deal of attention.

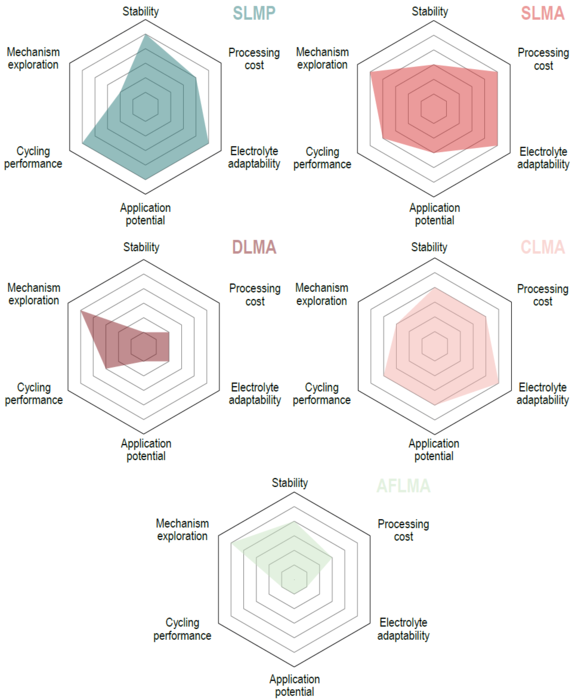

Radar plots of the performance properties of stabilized lithium-metal powder (SLMP), stabilized lithium-metal anode (SLMA), deposited lithium-metal anode (DLMA), composite lithium-metal anode (CLMA) and anode-free lithium-metal anode (AFLMA). Image Credit: ©Science China Press.

Radar plots of the performance properties of stabilized lithium-metal powder (SLMP), stabilized lithium-metal anode (SLMA), deposited lithium-metal anode (DLMA), composite lithium-metal anode (CLMA) and anode-free lithium-metal anode (AFLMA). Image Credit: ©Science China Press.

Lithium metal electrode holds a low electrode potential and could express a capacity that is as high as 3860 mAh g-1. Along with high energy density, lithium metal anodes display great potential for application.

But there are difficulties associated with improving practical lithium metal batteries as the lithium metal anode in lithium metal batteries is highly reactive which can result in safety implications.

At the Fudan University, Xiaoli Dong and Yongyao Xia et al. reported a review article in the National Science Review.

The study considered failure mechanisms and current research on practical lithium metal anodes, thereby offering designs for investigation in the future.

Generally, the lithium metal’s usage efficiency is low in lithium metal batteries, which hugely reduces its lifespan. Lithium metal exhibits high reactivity and is also sensitive to air and moisture, thereby making them fail and causing safety problems.

Two significant failure modes (short-circuiting and capacity loss) of lithium metal anodes were analyzed by the scientists. Lithium dendrite is the primary cause of short-circuiting: conditions like non-uniform lithium-ion concentration distribution would streamline the growth of lithium dendrite, which could enter via the separator and lead to short-circuiting.

Primarily, the capacity decay comes from irreversible reactions of lithium metal with lithium metal dusting and electrolytes. Due to lithium metal’s high reactivity, a certain amount of active lithium metal would respond with electrolyte and result in capacity degradation.

At the same time, a dusting of lithium metal during the process of charge and discharge would increase the consumption capacity and impedance of batteries. After discovering two significant failure mechanisms of lithium metal anodes, the scientists could conduct their investigation in a more targeted manner and engineer more practical lithium metal anodes.

Later, scientists reviewed and examined these targeted works. As per the making methods and equivalent applications, five categories of lithium anodes are suggested: stabilized lithium-metal powder anode (SLMP), deposited lithium-metal anode (DLMA), composite lithium-metal anode (CLMA), lithium-metal anode (SLMA) and anode-free lithium-metal anode (AFLMA).

Opportunities for the practical application of such anodes are evaluated by comparing their pros and cons. SLMP can ably compensate for the irreversible capacity of commercial anodes like graphite; SLMA can efficiently prevent the dusting of lithium metal and redress the dendrites.

DLMA ably regulates the presence of the anode interface. However, it is complex to make; CLMA can develop a dependable electrode structure, avoiding a complex preparation process. AFLMA utilizes copper as an anode, streamlining the manufacturing process of batteries.

Decisively, SLMA could be considered the most hopeful and practical lithium metal anodes amongst the five anodes reviewed; and SLMP can be the main candidate for energy-dense lithium metal batteries.

There is still a big gap between current technology and practical lithium metal anodes, even though lithium metal anodes have been analyzed extensively and in full by present research.

As the growth of cutting-edge characterization and manufacturing techniques advances, the mechanisms of lithium metal batteries will be analyzed in a more elaborate manner, and preparation techniques will be enhanced. Keeping this in mind, society is not so far away from the advent of safe and energy-dense lithium metal batteries, which can result in the energy revolution.

Journal Reference:

Li, P., et al. (2022) The pathway toward practical application of lithium-metal anodes for nonaqueous secondary batteries. National Science Review. doi.org/10.1093/nsr/nwac031.