By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.May 17 2022

By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.May 17 2022In an article recently published in the journal Bioprinting, researchers presented in vitro analysis of the bioactivity of printable calcium polyphosphate cement for bone tissue engineering.

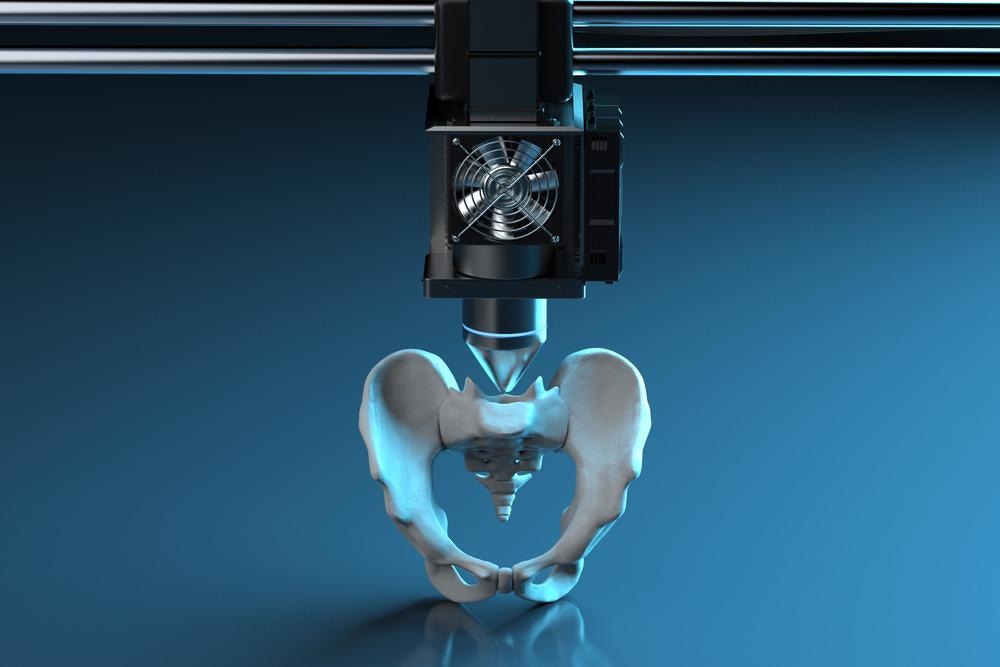

Study: Bioactivity evaluation of printable calcium polyphosphate/alginoplast cement for bone tissue engineering; In vitro study. Image Credit: Phonlamai Photo/Shutterstock.com

Background

Due to aging and trauma, bone is the second most commonly used tissue in surgery worldwide. With the development of 3D bone replacement-based biomaterials, bone tissue engineering (BTE) could reduce the risk of disease transmission and surgical rejection in autografts and allografts. To mend the fractures, a 3D biocompatible bone replacement that is biologically compatible and mimics the extracellular matrix (ECM) of real bone tissue is required.

Many types of research have shown that composite biomaterials with ceramic and polymeric components are desirable for the replacement of BTE. Calcium phosphate cement (CPC) is a potential biomaterial that offers numerous benefits.

Recently, three-dimensional printing (3DP) or additive manufacturing (AM) technology has shown promise in constructing a patient-specific scaffold. Binder jetting-based 3D plotting and 3D printing are the most prevalent technologies for the printing of 3D calcium phosphate cement scaffolds. To make this cement, calcium phosphate can be coupled with binding polymeric solution and powder to boost mechanical strength, hydrophilicity, and precision. Alginoplast (ALG) is a biocompatible and hydrophilic alginate-derived organic component widely employed in scaffold production and tooth molding applications.

About the Study

In this study, the authors discussed the development of a unique printable calcium polyphosphate (CPP) powder by the addition of ALG to manufactured 3D cement utilizing low-temperature binder jetting-based 3D printing without any sintering. Immersion in simulated body fluid (SBF) solution, freeman technology, and MG63 human osteoblast-like cell cultures were used to investigate the powder flowability and biological aspects of 3D cement. On the 3D cement surface, appropriate MG63 osteoblast-like cell attachment was cultivated.

The team improved the flowability of CPP powder and the self-hardening of 3D cement samples with the addition of ALG powder. The flowability of the powder was assessed to establish the impact of ALG on flowability qualities. The 3D cement samples were then printed by using the low-temperature and binder jetting-based 3D printing with a calcium phosphate cement composition of CPP/Ca(OH)2/ ALG as the powder phase and glycerol/ethylene glycol diacetate (GLY/EGD) as the binder phase. In the next phase, the created 3D cement samples were immersed in the SBF solution for the testing of bioactivity in vitro. In addition, cell survival and proliferation of MG63 human osteoblast-like cells were used to assess 3D cement biocompatibility.

The researchers used the human osteoblast-like MG63 cell line to test the biocompatibility of 3D cement. Immersion samples in SBF solution at 37 °C were used to assess the bioactivity potential of 3D cement. The powder morphology and surface of 3D cement were examined using a scanning electron microscope (SEM). The indirect cell culture approach was used to assess the biocompatibility of 3D cement. 3D cement samples were autoclave sterilized at 120 °C for 20 minutes. The mean standard deviation (SD) from three replications of each sample was used to calculate statistical results.

Observations

In comparison to other 3D cement extractions, 3D cement extraction after 72 hours of incubation showed a substantial change in optical density (OD) value. The phosphate absorption bands were found at 565 cm-1 as triple bending vibration ʋ4PO43- and double band at around 1090 cm-1 as asymmetric tensile vibration ʋ3PO43- in the apatite structure. Due to the interaction between calcium and carbonate ions under the physiological pH circumstances, calcium carbonate was also found in the X-ray diffraction (XRD) pattern at 29.4°.

The pH of 3D cement in DMEM cell culture medium dropped from 7.8 to 6.9 after 72 hours due to brushite phase breakdown. The addition of 10% ALG to CPP improved powder flowability, according to Freeman technology. The addition of ALG increased the flowability of CPP powder. After three weeks of immersion in the SBF solution, the benefit of biological activity and cauliflower-like apatite development was noticed. ALG in 3D cement could increase MG63 cell growth without causing toxicity.

The cauliflower-like carbonate apatite production on the 3D cement surface after 21 days of immersion demonstrated the high bioactivity potential of 3D cement containing ALG. With the increase in the cell culture time in 3D cement extraction, the number of cells which demonstrated 3D cement biocompatibility increased.

Conclusions

In conclusion, this study elucidated the low-temperature and binder jetting-based 3D printing of 3D cement samples based on printable powder and liquid phases. The team created a low-temperature printable CPP powder and liquid printing system. The ALG powder had a critical role in improving the printability of the PH10 powder phase, resulting in successful 3D printing samples.

The physicochemical parameters of the 3D cement revealed that after 21 days of immersion in the SBF solution, the original powder phase was completely transformed into cauliflower-like apatite. After seven days, the cellular biocompatibility experiments revealed a greater OD value than the control, indicating normal cell growth.

Furthermore, the MG63 cell morphology revealed a natural attachment to the 3D cement surface in the form of a spindle. The CPP/ALG 3D cement's new printable phases demonstrated acceptable biological and physicochemical qualities.

More from AZoM: What are Profile Roughness Parameters?

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Dreano, A., Favre, J., Desrayaud, C., et al. Bioactivity evaluation of printable calcium polyphosphate/alginoplast cement for bone tissue engineering; In vitro study. Bioprinting e00210 (2022). https://www.sciencedirect.com/science/article/pii/S2405886622000203