Reviewed by Alex SmithMay 24 2022

The creation of materials that can trap carbon dioxide emitted by a variety of industrial facilities is one potential option for addressing the rising climate catastrophe.

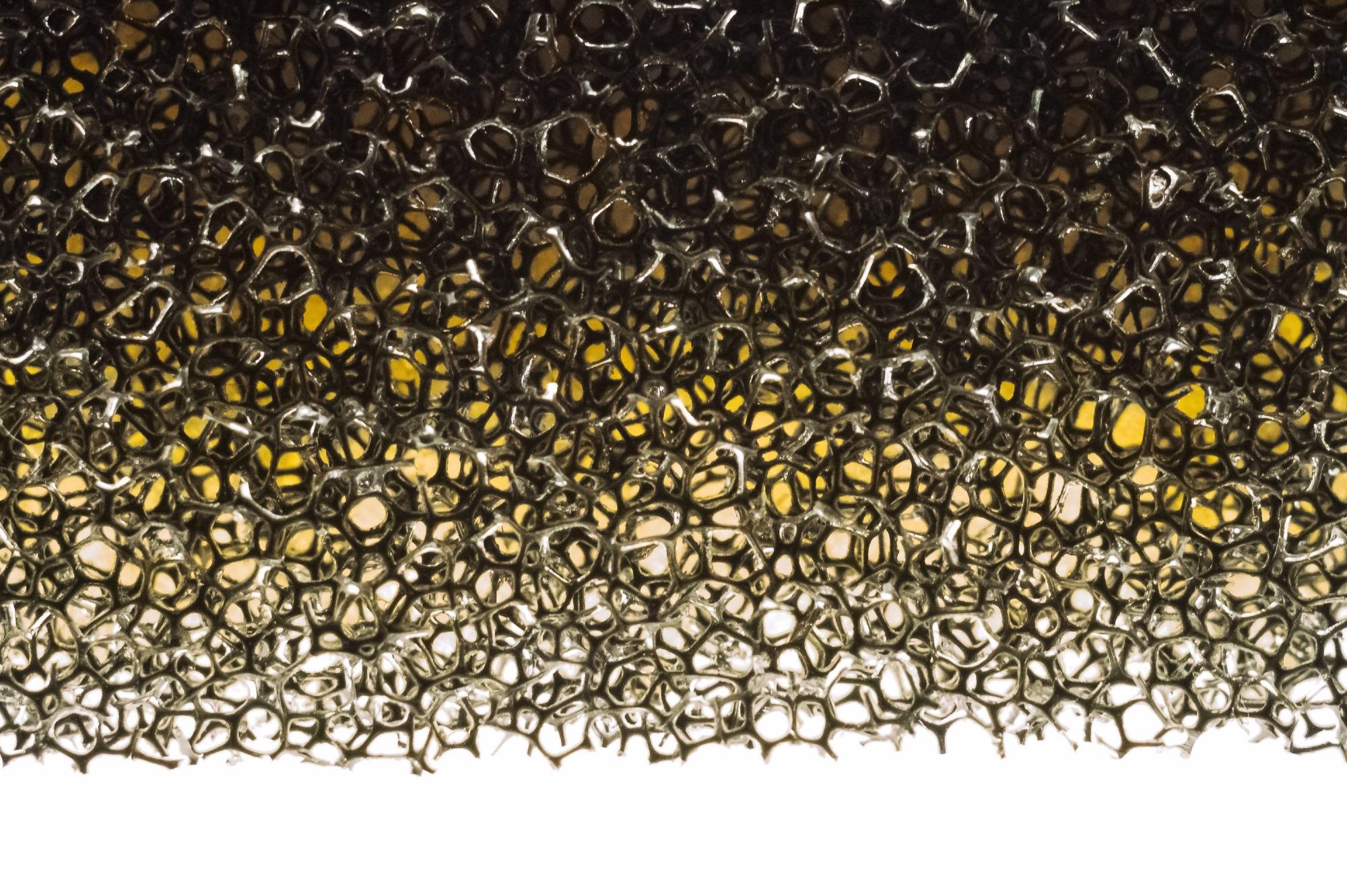

Image Credit: Shutterstock.com/ ylyastik

The enormous volume of material necessary to have an impact and the correspondingly high cost of making it is a major stumbling block. Furthermore, oxidation quickly degrades many of the major competitors for carbon capture.

The porous, sponge-like materials used in an international collaboration led by Phillip Milner, assistant professor of chemistry and chemical biology in the College of Arts and Sciences, can trap carbon dioxide in their cavities while letting other gases like nitrogen flow through.

The materials are created from sugar and low-cost alkali metal salts, making them affordable for large-scale deployment and potentially useful in reducing the environmental impact of coal-fired power stations.

A paper from the team was published in Angewandte Chemie on May 17th, 2022. Mary Zick, a Ph.D. student, is the lead author.

A procedure known as amine scrubbing has been the primary approach for carbon capture in chemistry for the last 100 years. Amines are nitrogen-containing organic molecules generated from ammonia. They can selectively extract carbon dioxide from gas mixtures in an aqueous solution.

However, after every cycle, oxygen damages them, meaning that they need more and more of the material to be manufactured, increasing the expense.

Milner’s lab has been working with a different family of materials and developing them exclusively for CO2 capture, rather than trying to solve the amine oxidation problem.

The new research is centered on sponge-like materials with hydroxide sites in their pores. Typically, hydroxide salt solutions reversibly react with carbon dioxide to generate bicarbonate salts, like baking soda, which trap the CO2.

However, to renew the hydroxide salt, the material must be heated to 500 to 800 °C, which is neither a simple task nor cheap.

Zick discovered that by using cyclodextrins as a starting material and boiling them with alkali metal salts in water, she could make a sponge-like material with pores in which carbon dioxide bonds firmly but other gases such as nitrogen flow through freely.

We expose the material to mixtures of carbon dioxide and nitrogen and see if they can absorb the carbon dioxide and ignore the nitrogen, which is the major component of air and emission streams.

Phillip Milner, Assistant Professor, Chemistry and Chemical Biology, College of Arts and Sciences

Milner added, “The underlying chemistry is really the same as what happens with hydroxide solutions in water. But by doing it in these sponge-like materials, you gain a lot of advantages. The carbon-dioxide capture is very fast, it can have a very high capacity and it may be very stable to oxygen.”

CO2 can be released at low temperatures of 80 to 120 °C due to the reversible processes. In addition to separations, the material’s tunability makes it valuable for a variety of applications, including medication delivery, catalysis and gas storage.

“Coal emissions are still the No. 1 anthropogenic contributor to carbon-dioxide emissions in the world. What s nice about this work is that Mary not only found a material that’s useful for carbon-dioxide capture from coal flue gas, but she outlined the structure-property relationships that will allow us to design materials for other applications, like capturing CO2 from natural gas fired power plants, as well as maybe even from air, which is one of the really big challenges of our time”, stated Milner.

The apparatus that Zick custom-built to see if a gas combination can be separated in a solid medium—a previously inaccessible capability at the university—is an added perk of the research. Milner’s lab is already testing samples from other Cornell researchers with the modular device.

Milner further added, “We have got people coming out of the woodwork to do these experiments. We have a little hub now. If somebody brings us some material, in a week or two Mary can tell you if it is promising for carbon-dioxide capture.”

Suzi Pugh and Alexander Forse of the University of Cambridge and Jung-Hoon Lee of the Korea Institute of Science and Technology are the co-authors.

The U.S. Department of Energy provided funding for the study. The Cornell Center for Materials Research, funded by the National Science Foundation’s MRSEC program, was utilized by the researchers.

Journal Reference:

Zick, M. E, et al. (2022) Carbon Dioxide Capture at Nucleophilic Hydroxide Sites in Oxidation-Resistant Cyclodextrin-Based Metal-Organic Frameworks. Angewandte Chemie doi/10.1002/anie.202206718.