Chemical reactions powered by light are extremely helpful to chemists who are developing new methods to make pharmaceuticals and other beneficial compounds. Exploiting this light energy necessitates photoredox catalysts, which can capture light and convey the energy to a chemical reaction.

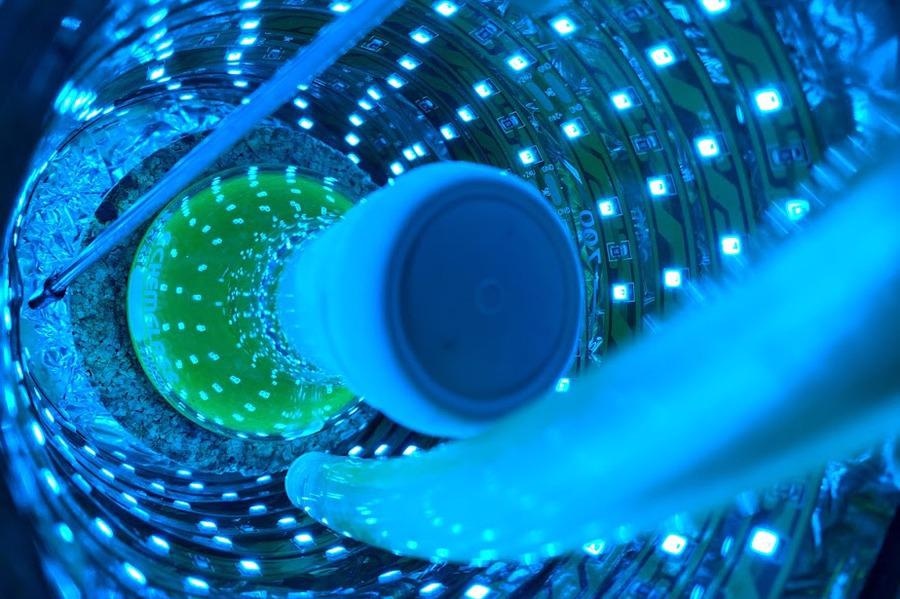

MIT chemists have designed a new type of photoredox catalyst that could make it easier to incorporate light-driven reactions into continuous flow manufacturing processes. The polymer catalysts could be used to coat tubing and perform chemical transformations on reactants as they flow through the tube, as imagined in this digital artwork. Image Credit: Richard Liu

MIT chemists have designed a new type of photoredox catalyst that could make it easier to incorporate light-driven reactions into continuous flow manufacturing processes. The polymer catalysts could be used to coat tubing and perform chemical transformations on reactants as they flow through the tube, as imagined in this digital artwork. Image Credit: Richard Liu

MIT chemists have recently developed a new kind of photoredox catalyst that could make it easier to integrate light-powered reactions into manufacturing methods. In contrast to most currently available photoredox catalysts, the new group of materials is insoluble, so they can be used repeatedly. These catalysts can be employed to coat tubing and carry out chemical alterations on reactants as they travel via the tube.

Being able to recycle the catalyst is one of the biggest challenges to overcome in terms of being able to use photoredox catalysis in manufacturing. We hope that by being able to do flow chemistry with an immobilized catalyst, we can provide a new way to do photoredox catalysis on larger scales.

Richard Liu, Postdoctoral Researcher and Study Joint Lead Author, MIT

The new catalysts, which can be altered to carry out many diverse types of reactions, can also be integrated into other materials such as particles or textiles.

Timothy Swager, the John D. MacArthur Professor of Chemistry at MIT, is the senior author of the study, which has been recently published in the journal Nature Communications. Sheng Guo, an MIT research scientist, and Shao-Xiong Lennon Luo, an MIT graduate student, are also authors of the study.

Hybrid Materials

Photoredox catalysts function by absorbing photons and then utilizing that light energy to drive a chemical reaction, similar to the way chlorophyll in plant cells absorbs energy from the sun and utilizes it to make sugar molecules.

Chemists have created two core groups of photoredox catalysts, which are called heterogenous and homogenous catalysts. Homogenous catalysts typically comprise organic dyes or light-absorbing metal complexes. These catalysts can be easily modified to carry out a particular reaction, but the problem is that they dissolve in the solution where the reaction occurs. This means that they cannot be simply extracted and used again.

On the other hand, heterogenous catalysts are solid minerals or crystalline materials that create 3D structures or sheets. These materials do not dissolve, therefore they can be used many times. However, these catalysts are tougher to modify to attain a preferred reaction.

To integrate the advantages of both of these kinds of catalysts, the scientists planned to insert the dyes that constitute homogenous catalysts into a solid polymer. For this application, the scientists utilized a plastic-like polymer with minute pores that they had earlier created for carrying out gas separations.

In this research, the scientists showed that they could integrate nearly 12 diverse homogenous catalysts into their new hybrid material, but they are certain it could work with several more.

These hybrid catalysts have the recyclability and durability of heterogeneous catalysts, but also the precise tunability of homogeneous catalysts. You can incorporate the dye without losing its chemical activity, so, you can more or less pick from the tens of thousands of photoredox reactions that are already known and get an insoluble equivalent of the catalyst you need.

Richard Liu, Postdoctoral Researcher and Study Joint Lead Author, MIT

The scientists learned that adding the catalysts into polymers also enabled them to become more effective. One explanation is that reactant molecules can be contained in the polymer’s pores, ready to react. Furthermore, light energy can effortlessly flow along the polymer to locate the waiting reactants.

The new polymers bind molecules from solution and effectively preconcentrate them for reaction. Also, the excited states can rapidly migrate throughout the polymer. The combined mobility of the excited state and partitioning of the reactants in the polymer make for faster and more efficient reactions than are possible in pure solution processes.

Timothy Swager, Study Senior Author and John D. MacArthur Professor of Chemistry, MIT

Higher Efficiency

The scientists also demonstrated that they could tweak the physical features of the polymer backbone, including its porosity and thickness, according to the application they wanted to employ the catalyst for.

As one example, they demonstrated that they could produce fluorinated polymers that would adhere to fluorinated tubing, which is frequently used for continuous flow manufacturing. During this kind of manufacturing, chemical reactants pass via a series of tubes while new constituents are incorporated, or other steps such as separation or purification are carried out.

At present, it is challenging to add photoredox reactions into continuous flow processes because the catalysts rapidly deplete, so they have to be constantly incorporated into the solution.

Adding the new MIT-designed catalysts into the tubing used for this type of manufacturing could enable photoredox reactions to be carried out during continuous flow. The tubing is clear, letting light from an LED pass through and reach the catalysts and stimulate them.

The idea is to have the catalyst coating a tube, so you can flow your reaction through the tube while the catalyst stays put. In that way, you never get the catalyst ending up in the product, and you can also get a lot higher efficiency.

Richard Liu, Postdoctoral Researcher and Study Joint Lead Author, MIT

The catalysts could also be employed to coat magnetic beads, rendering them easier to extract out of a solution once the reaction is completed, or to coat reaction textiles or vials. The scientists are currently attempting to integrate a wider range of catalysts into their polymers and engineering the polymers so that they can be employed in various potential applications.

The National Science Foundation and the KAUST Sensor Initiative funded the study.

Journal Reference:

Liu, R. Y., et al. (2022) Solution-processable microporous polymer platform for heterogenization of diverse photoredox catalysts. Nature Communications. doi.org/10.1038/s41467-022-29811-6.