Writing in the journal Cryogenics, a team of scientists from the Korea Aerospace Research Institute has evaluated the performance of a helium heat exchanger for launch vehicles. Performance was evaluated under real engine operating conditions.

Study: Thermal performance evaluation and analysis of helium heat exchanger for cryogenic propellant launch vehicle.Image Credit: karnoff/Shutterstock.com

Launch Vehicles

Efficient launch vehicle design is vital for the spacetech industry. Technology has advanced since the early days of space travel, but the basic principle of a launch vehicle remains the same.

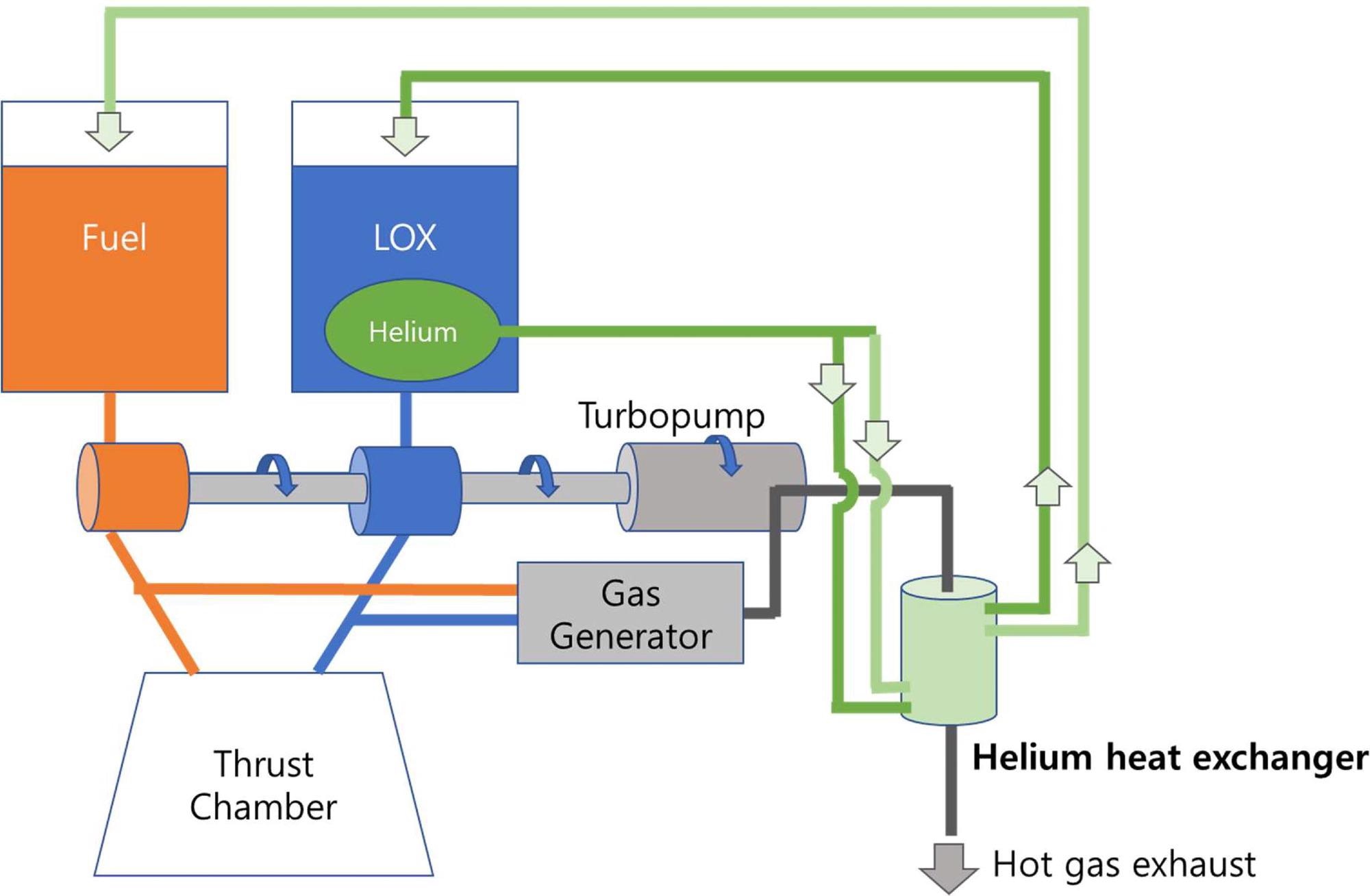

Launch vehicles typically employ helium gas to pressurize the fuel required for flight and the vehicle’s oxidation tanks. Turbo pumps transfer propellant from the propellant tank, which is under low pressure, to the high-pressure combustion chamber. Cavitation at the inlet is avoided by transferring propellants from the propellant tank to the turbopumps.

Schematic of a LOX–kerosene launcher propulsion system with a helium heat exchanger. Image Credit: Baek, S et al., Cryogenics

In liquid oxygen and kerosene launch systems, helium is stored at extremely low temperatures, which increases the density of the gas and, in turn, gas volume. This allows the helium reservoir tanks to be lightweight and compact.

Supplying the required pressure to aid lift-off is not as effective at the cryogenic temperatures helium needs to be stored at, however. To overcome this issue, the helium gas must be heated by external heat sources, causing the gas to expand. Due to the limited energy provided to the launch vehicle, there is a need for efficient energy management and conversion.

Previous Efforts

Conventional methods to address this problem involve providing combustion gases in thrust chambers and gas generators to heat the helium gas to high temperatures (around 600 K.)

The Saturn V rocket employed a 4-coil shell-and-tube heat exchanger to vaporize helium gas and provide propellant pressurization. The heat source for this process was the turbine’s exhaust gases. Liquid oxygen has been employed to provide the necessary heating to aid helium gas pressurization in various launch vehicles.

Other launch vehicles have used engine regenerative cooling jackets to provide fuel tank pressurization. Recent research has explored liquid helium heating methods, including exploring the use of this strategy in lunar excursion modules. Heat exchangers have displayed better efficiency and lower weight than conventional methods, though further testing is required for this method.

Heat Exchangers

Recent studies have sought to improve the efficiency of heat exchangers to aid future launch vehicle design. Experimental setups have been designed which use helium in a propellant tank pressurization system and demonstrate cryogenic helium heater performance.

One system design by Lee et al. has employed a liquid nitrogen heat exchanger. In this system, hot gas is not generated, as an electrical heater provides the heat source. The system has a shell-and-tube shape, much like conventional systems such as the Saturn V launch vehicle. Another study has utilized steam to heat the gases.

Utilizing heat exchangers in launch vehicles provides opportunities for designing advanced space vehicles with enhanced performance, lower weight, and satisfactory and stable heat transfer. Whilst there have been significant advances in lab-based studies, real-world analysis and evaluation of heat exchangers have been insufficient.

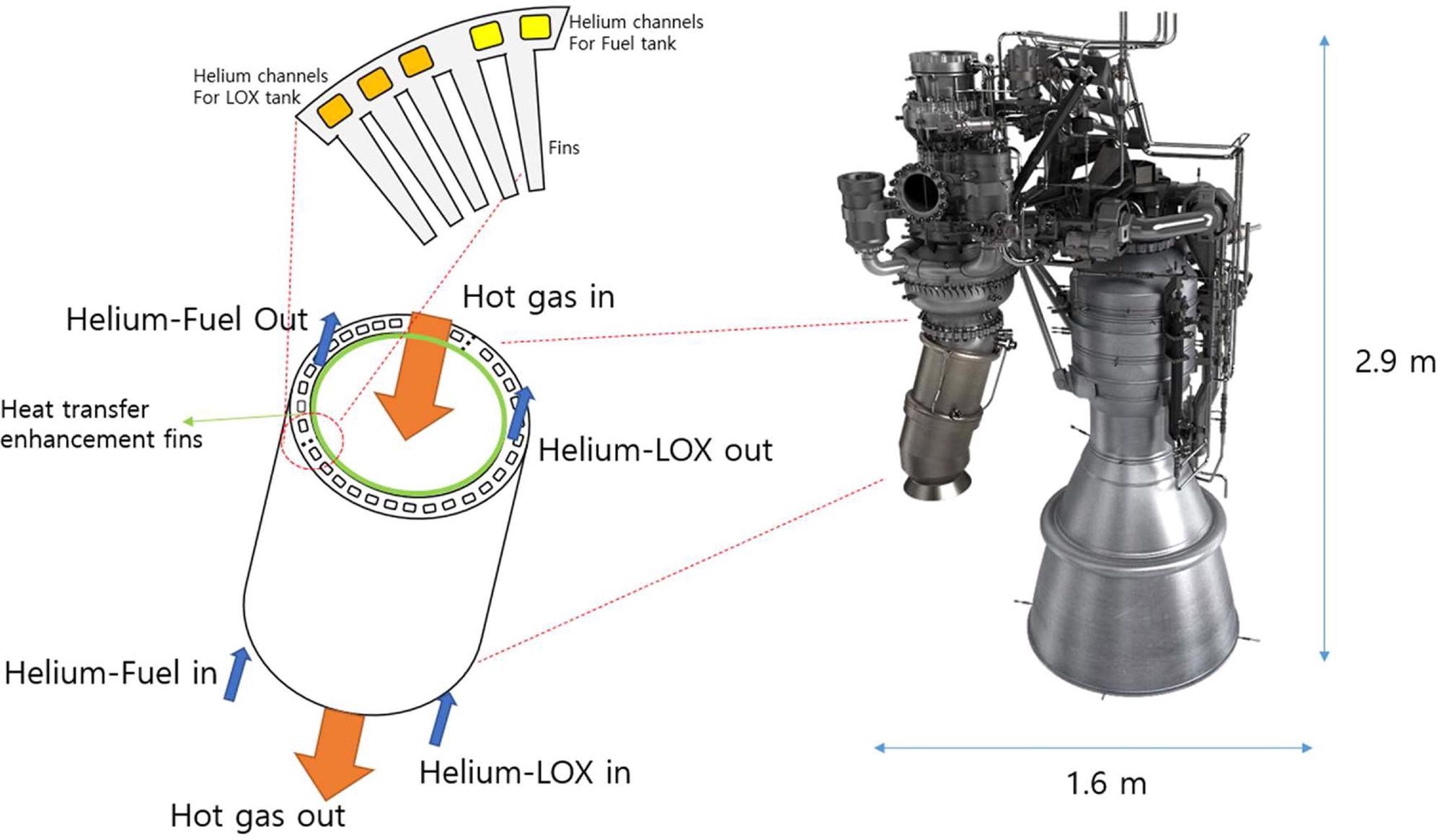

Configuration of helium/hot-gas heat exchanger for KSLV-II 75-tonf engine. Image Credit: Baek, S et al., Cryogenics

The Study

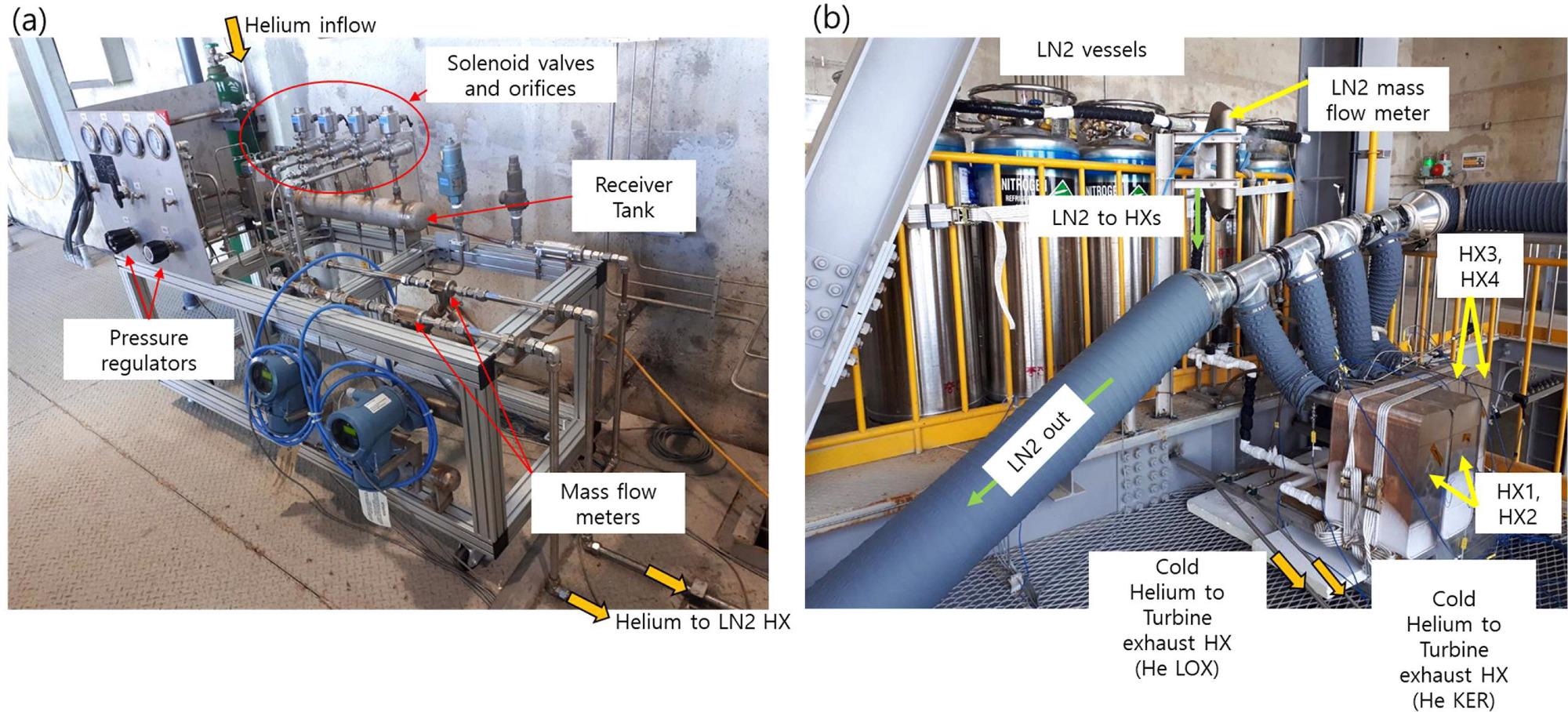

The new paper in Cryogenics has developed test methods for launching vehicle heat exchangers. The heat exchanger has a cylindrical minichannel design rather than the shell-and-tube configuration of previous systems. Plate heat exchangers were employed in the system to cool helium from 300 K to 90 K.

The authors developed a numerical model to characterize the exchanger and improve the efficiency of heat exchange between combustion gas and helium. The heat exchanger system evaluated in the research will be installed in the KSLV-II launch vehicle, which is currently under construction.

Study Findings

The KSLV-II helium heat exchanger’s performance was extensively evaluated in the research paper. Two types of experiments were performed. Firstly, helium gas was supplied under constant mass flow in a combustor test facility. The second experiment involved testing performance in a full-engine assembly. Gradually decreasing helium flow rates were supplied in this second experiment.

Thermal performance in both tests was similar to the author’s numerical simulations. The authors observed an interesting phenomenon in the tests. Cryogenic helium was utilized by the launch vehicle’s propulsion system when inlet temperature varied from cryogenic temperatures to ambient temperatures.

When the inlet temperature was 300 K, the effectiveness of the heat exchanger was one percent higher than at cryogenic temperatures. Models confirmed that the heat transfer coefficient of the system was affected by inlet temperature. At lower inlet temperatures, there was a 6% decrease in effectiveness. Simple modeling was used to confirm the heat exchanger design technique.

Photographs of (a) helium distribution system and (b) plate heat exchangers for cooling the helium gas using liquid nitrogen. Image Credit: Baek, S et al., Cryogenics

In Summary

The study has demonstrated an effective method for analyzing and evaluating the performance of heat exchanger modules in a real launch system, which addresses several current problems in propulsion design utilizing this technology. The study’s findings will help to design more efficient, low-weight next-generation propulsion systems for launch vehicles.

Further Reading

Baek, S et al. (2022) Thermal performance evaluation and analysis of helium heat exchanger for cryogenic propellant launch vehicle Cryogenics 103492 [online, pre-proof] sciencedirect.com. Available at: https://www.sciencedirect.com/science/article/pii/S0011227522000741?via%3Dihub

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.