In an article recently published in the open-access journal Polymers, researchers aimed to prepare a composite film consisting of chitosan biguanidine hydrochloride (CBg) and poly (N-vinyl-2-pyrrolidone) (PVP) to be utilized as coatings for fresh agricultural products like fruit. The application of the coatings was evaluated on strawberries, and it was observed that the film had good antibacterial, water vapor barrier, solubility, mechanical, and transparency properties.

Study: Chitosan Biguanidine/PVP Antibacterial Coatings for Perishable Fruits. Image Credit: elena_prosvirova/Shutterstock.com

Background

Fresh farm products like fruits have a short shelf life and hence are highly perishable. The major causes of food degradation are water loss, microbial growth, texture degradation, and respiration.

The shelf life of fruits can be preserved by controlling such factors. Methods like modified atmospheric packaging and refrigeration are commercially used preservation techniques but are costly owing to special equipment and energy consumption.

Wax or paraffin-based coatings can alter the taste of fruits. Films made from polysaccharides and proteins have been used increasingly due to their biodegradability, miscibility, and edibility, but they do not exhibit characteristics like material flexibility, preservation effects, high transparency, antibacterial properties, and washability. Thus, the development of a better film coating material is deemed essential.

Although a natural polysaccharide with antibacterial activity, chitosan (CS) is limited in function as a fruit coating due to poor mechanical strength and low solubility of pH>6.5. Polymers such as PVP have good biocompatibility, water-solubility, and low cytotoxicity, while CBg, a guanidine derivative of CS, exhibited improved antibacterial properties and solubility compared to CS. The study aimed to eliminate the limitations of CS-based fruit coatings by preparing a CBg coating with antibacterial properties.

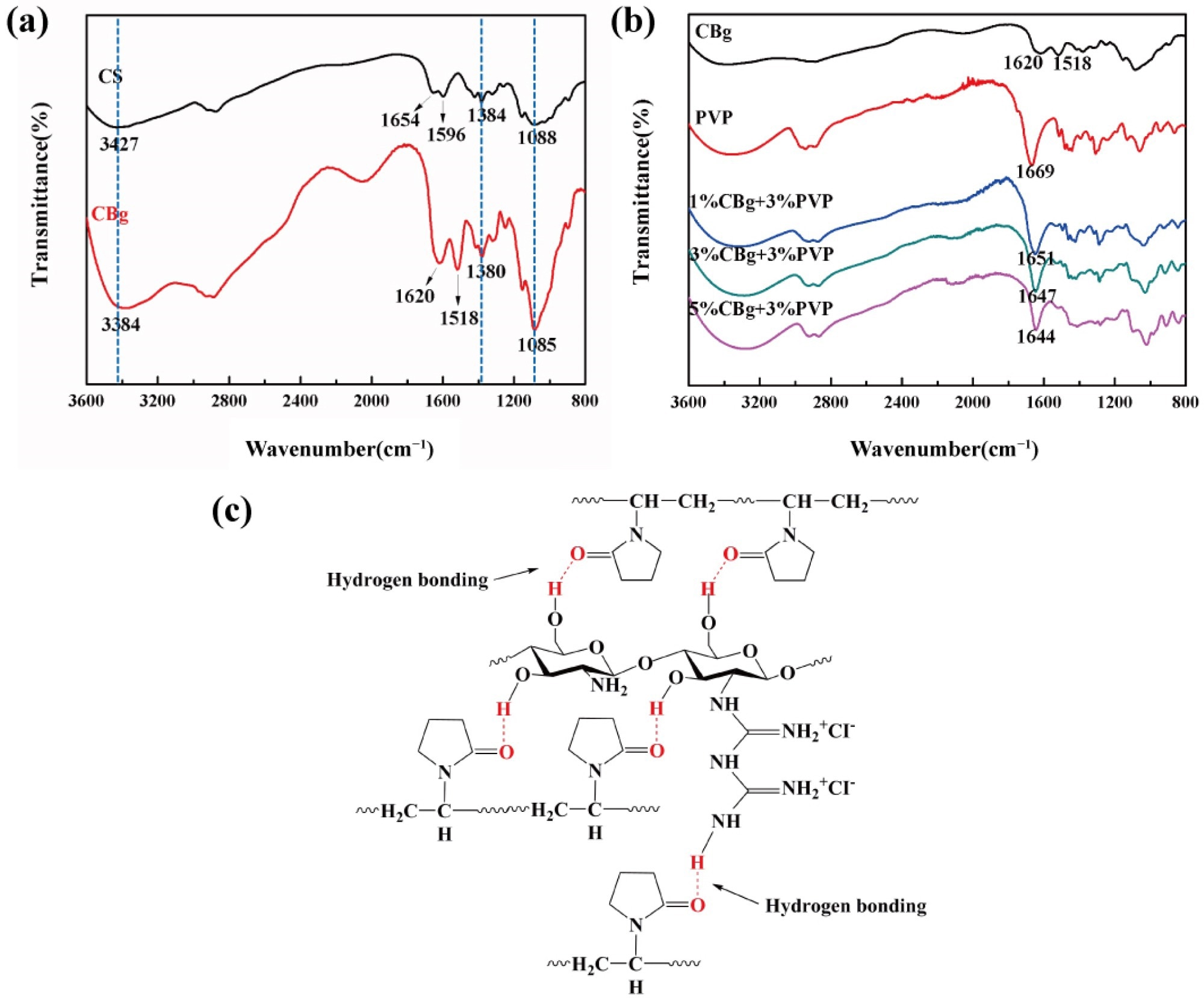

(a) FTIR spectra of CS and its derivative CBg. (b) FTIR spectra of CBg, PVP, and CBg/PVP films with different mass concentrations. (c) Schematic diagram of the interaction between CBg and PVP. Image Credit: Jiao, X et al., Polymers

About the Study

The researchers used cyanoguanidine, CS, methanol, and HCl to prepare the CBg powder. A CBg/PVP film was subsequently made. Individual CS, CBg, and CBg/PVP films were characterized based on various parameters, such as infrared spectra, tensile properties, water vapor permeability, and solubility. Antibacterial properties were measured against strains of Escherichia coli (E. coli) and Staphylococcus aureus (S. aureus).

The team used strawberries to evaluate the functioning of CBg/PVP films since it has a tremendously short shelf life while having exceptional organoleptic properties with great nutritional value. The strawberries used for the application were of similar qualities and did not bear any defects. The strawberries were completely soaked in the composite solution and dried at room temperature. A total of eight strawberries comprised one set of samples.

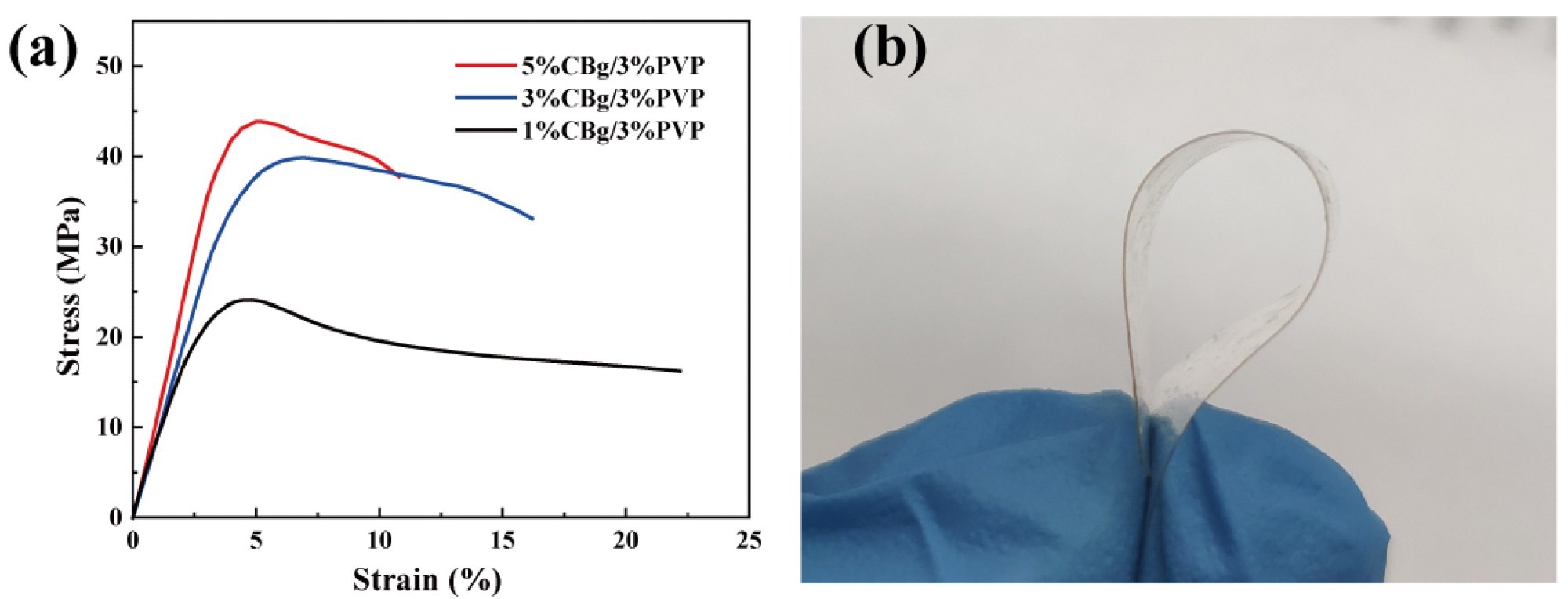

(a) Tensile testing of CBg/PVP films with different mass concentrations. (b) Photograph of 3% CBg/3% PVP film. Image Credit: Jiao, X et al., Polymers

Observations

Fourier transform infrared (FTIR) spectroscopy helped determine the interaction between CS and its counterpart polymers. The PVP-CBg interaction was enhanced with an increase in the CBg content. The addition of CBg was observed to have minimal impact on the film’s transparency. Young’s modulus of the film increased due to the increase in the cross-linking polymer chains. This, coupled with the increase in tensile strength, pointed towards an enhancement in the mechanical characteristics of the film.

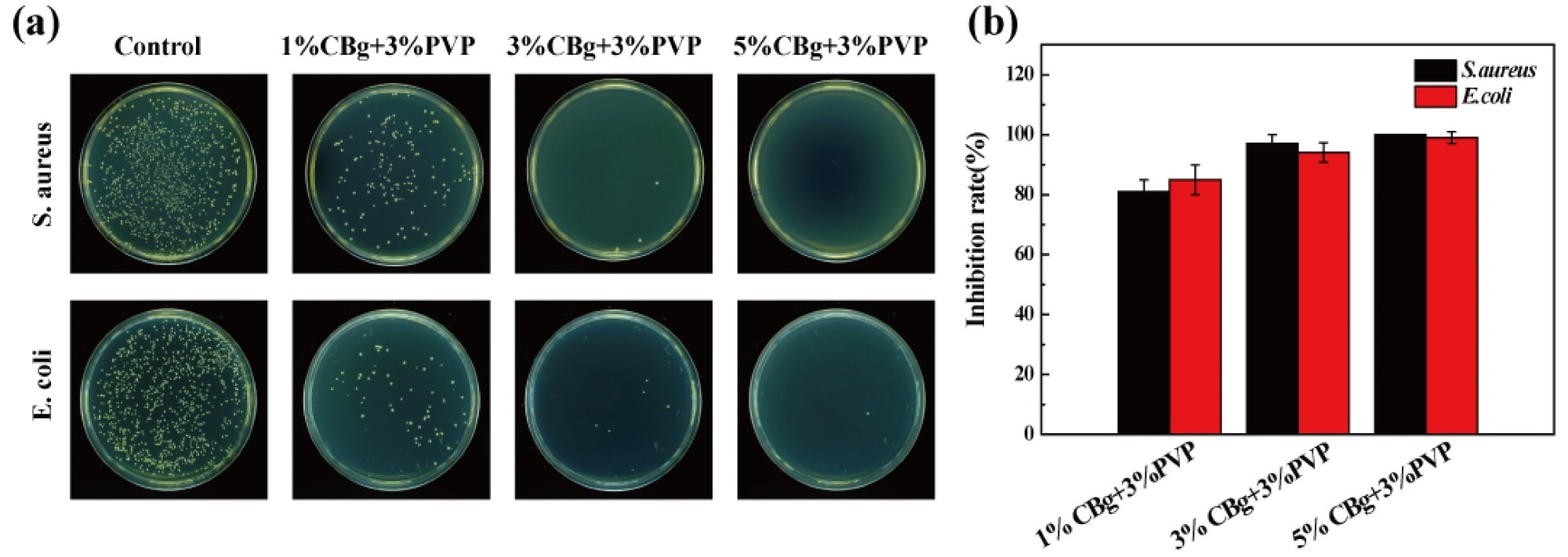

The water vapor permeability decreased with greater CBg content, which could be the result of the interconnected network formed by the cross-linking between CBg and PVP. Although the films’ solubility percentage (Sol%) decreased as the CBg content increased, the CBg/PVP coating could easily be removed through washing and mild rubbing. The increased density of positively charged amino groups due to the increased CBg content could strongly change the permeability of the bacteria and cause its death.

Additionally, the strawberries with the coatings had no mold growth even at four days, while the uncoated strawberries exhibited mold growth after two days. The mass loss due to water evaporation was significantly lower in coated strawberries. Consequently, the firmness was also reduced at a slower pace in the coated strawberries.

(a) Antibacterial effect of different CBg/PVP films on S. aureus and E. coli. (b) Inhibition rate of different CBg/PVP films. Image Credit: Jiao, X et al., Polymers

Conclusions

To summarize, the team prepared antibacterial fruit coatings based on CBg and PVP, which showed excellent mechanical strength while remaining highly flexible due to the increased cross-linking of the polymer chains. The coating of strawberries with this film also exhibited a reduction in the rate of mass loss, softening, and water vapor permeability, thus delaying the degradation of the fruit. Furthermore, the film is transparent and washable and hence does not modify the physical and biological properties of the fruits.

Although the increased cross-linking of the polymers caused a decrease in the solubility of the film, gentle scrubbing and washing with water can easily remove the coating. According to the authors, this method is a direct path to food preservation by increasing their shelf life and can help resolve the global food waste crisis.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Jiao, X.; Xie, J.; Hao, M.; Li, Y.; Wang, C.; Zhu, Z.; et. al. Chitosan Biguanidine/PVP Antibacterial Coatings for Perishable Fruits. Polymers 2022, 14, 2704. https://www.mdpi.com/2073-4360/14/13/2704