Bitumen deterioration is one of the key challenges in using recycled asphalt pavement (RAP) in hot mix asphalt (HMA); thus, the proportion of RAP in the HMA is restricted. The latest research published in Materials assesses the rheological characteristics of the RAP binding as well as the efficacy of HMA with a high RAP concentration while utilizing residual engine oil (WEO).

Study: Investigation of Waste Electrical Power Plant Oil as a Rejuvenating Agent for Reclaimed Asphalt Binders and Mixtures. Image Credit: DifferR/Shutterstock.com

Industrial Relevance of Bitumen

Bitumen is one of the most commonly used asphalt pavement binding ingredients. The paving sector consumes around 95 percent of all bitumen generated worldwide each year. Decreasing quantities of commonly accessible good-quality resources, escalating waste disposal issues, and soaring bitumen costs have contributed to increased use of recycled asphalt pavement (RAP) in infrastructure project development.

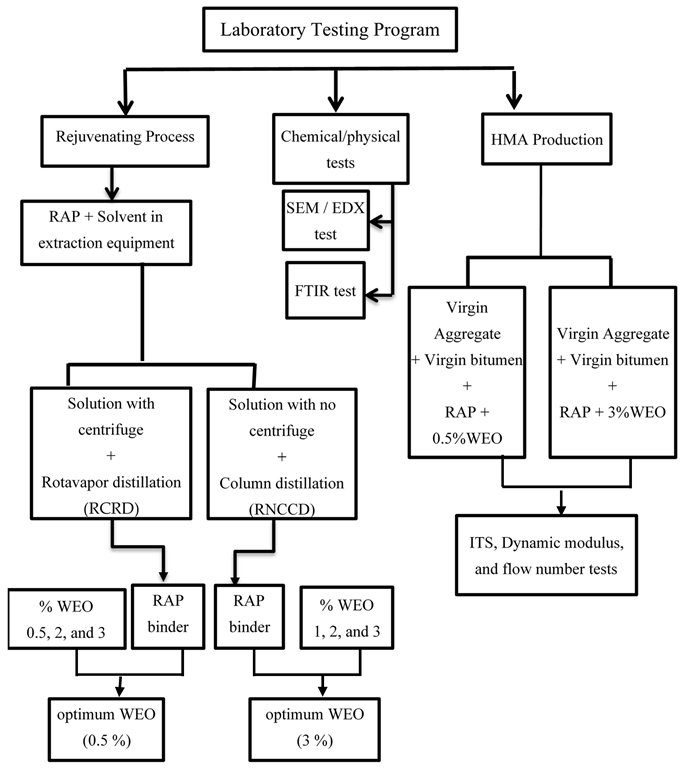

Experimental program flow chart. Image Credit: El-labbad EM et al., Materials

Pavement Recycling for Recycled Pavement Asphalt

The regeneration of pavements comprises the use of old or damaged materials in the creation of new pavements. When the proportion of RAP utilized in hot mix asphalt (HMA) approaches 25% or greater, the mixture design process considers the percentage of bitumen in RAP.

Moisture degradation, stress, and thermal degradation are practically expected to occur in repurposed high-RAP content blends when the bitumen stiffens. As a result, characterization of the RAP binder and aggregate is a critical stage in the design process.

Aging of RAP Binder - A Critical Problem

The main difficulty that has restricted the usage of RAP material to small percentages is the aging of the RAP binder. The aging of bitumen leads to excessive pavement crumbling. As a result, the expense of rebuilding and sustaining bituminous pavements is increasing.

The phrase "asphalt aging" most likely leads to variations in the rheological properties of the RAP binder caused by chemical and heat fluctuations. The aging of the RAP binder has a significant impact on its rheological characteristics, impacting the overall effectiveness of the asphalt pavement.

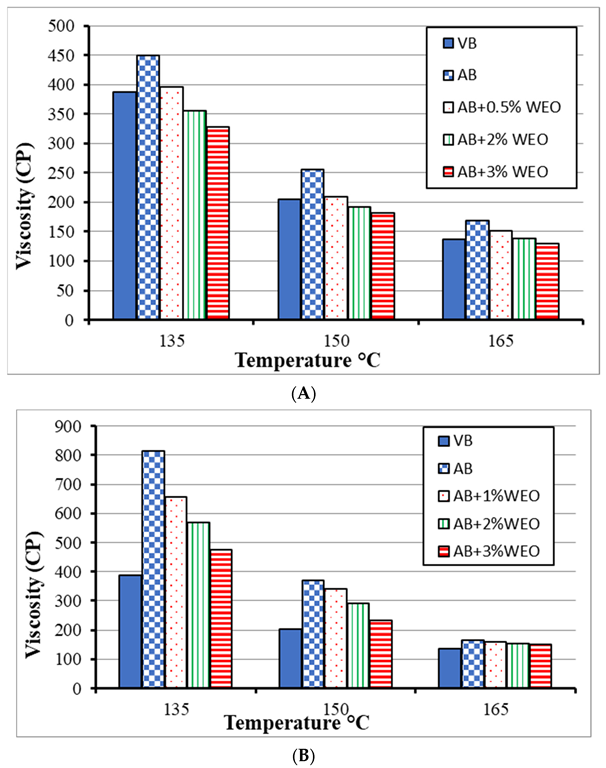

Brookfield viscosity of virgin, recovered, rejuvenated bitumen by WEO contents. (A) RCRD recovered aged binder; (B) RNCCD recovered aged binder. Image Credit: El-labbad EM et al., Materials

Importance of Rejuvenation Process

The most common method for restoring the characteristics of the RAP binder to a state similar to virgin bitumen is rejuvenation. Additives, renewing (recycling) compounds, and softening substrates are commercially available and can be used on RAP pavements. Recycling chemicals are an effective approach to reducing rigidity while increasing the percentage of RAP in the mix.

Recycling agent effectiveness is mostly determined by the initial source. The primary difference between softening and rejuvenating substances is that rejuvenating agents can preserve the chemical composition of aging bitumen.

Waste Oils as Source of Asphalt Rejuvenators

Manufacturing asphalt rejuvenators from waste oils have gained popularity in recent years. Filtration, separating, and blending are all common operations in the manufacture of rejuvenators. The rejuvenation system operates by restoring bitumen's colloid architecture and enhancing molecular mobility. Bio-oils can renew the aging binder.

They can be used to soften hard-aged bitumen and reduce the rigidity of binders and high-RAP content mixtures, according to recent research findings. Furthermore, according to a recent study, the inclusion of bio-binder increased the asphalt binder quality at high temperatures while decreasing it at low temperatures.

Waste engine oil (WEO) from energy plant machines is one of the likely urban waste resources that can be used to renew the RAP binder. It is a heavy-duty technologically modified oil blend that, when contrasted to automobile engine oils, retains the right viscosity of the oil under harsh working circumstances.

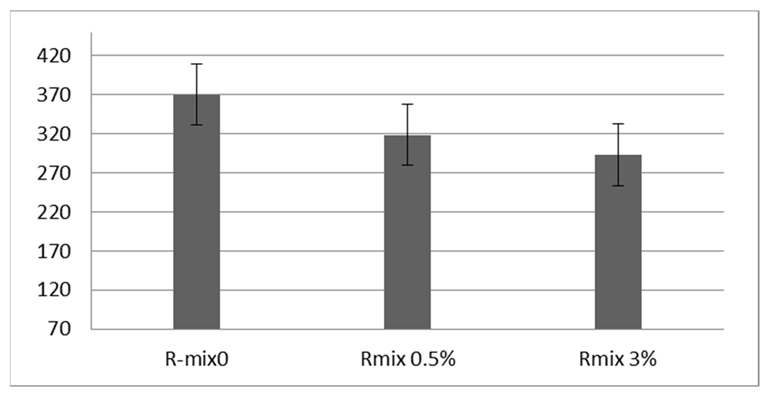

Flow Number Results. Image Credit: El-labbad EM et al., Materials

Research Findings

For the RCRD adhesive, the WEO was blended with the RAP binding material in proportions of 0.5, 2.0, and 3.0 percent by total bitumen mass. The inclusion of WEO lowered the softness point temperature of regenerated bitumen. The proportions of WEO attained for the RCRD and RNCCD recovered aged binders were 0.5 percent and 3 percent, respectively.

The high viscosity of old bitumen was the greatest. The viscosity values were comparable to virgin bitumen when 0.5 percent and 3 percent WEO were added to the recoverable bitumen for the RCRD and RNCCD reclaimed binders, respectively.

It was discovered that increasing WEO corresponded to a reduction in all morphological indices, implying a reduction in aging. The introduction of 3% WEO decreased the structural indices to those of the virgin binder. This decrease in sulfoxides and carbonyls indicates a chemical change in the asphalt binder. Furthermore, as the tensile stress ratio improved, so did the resilience to moisture damage.

In summary, adding WEO to the recycled mix weakened the RAP binder, lowering the cyclic modulus of the regenerated blends and rendering them more resilient to fatigue fracture.

Further Reading

El-labbad EM, Heneash U, El-Badawy SM. (2022). Investigation of Waste Electrical Power Plant Oil as a Rejuvenating Agent for Reclaimed Asphalt Binders and Mixtures. Materials. 15(14). 4811. Available at: https://www.mdpi.com/1996-1944/15/14/4811

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.