Scientists at Binghamton University have conducted research in collaboration with the Center for Functional Nanomaterials (CFN) — a U.S. Department of Energy (DOE) Office of Science User Facility at Brookhaven National Laboratory — to get a better understanding of how peroxides on the surface of copper oxide promote the oxidation of hydrogen but prevent the oxidation of carbon monoxide, enabling them to control oxidation reactions.

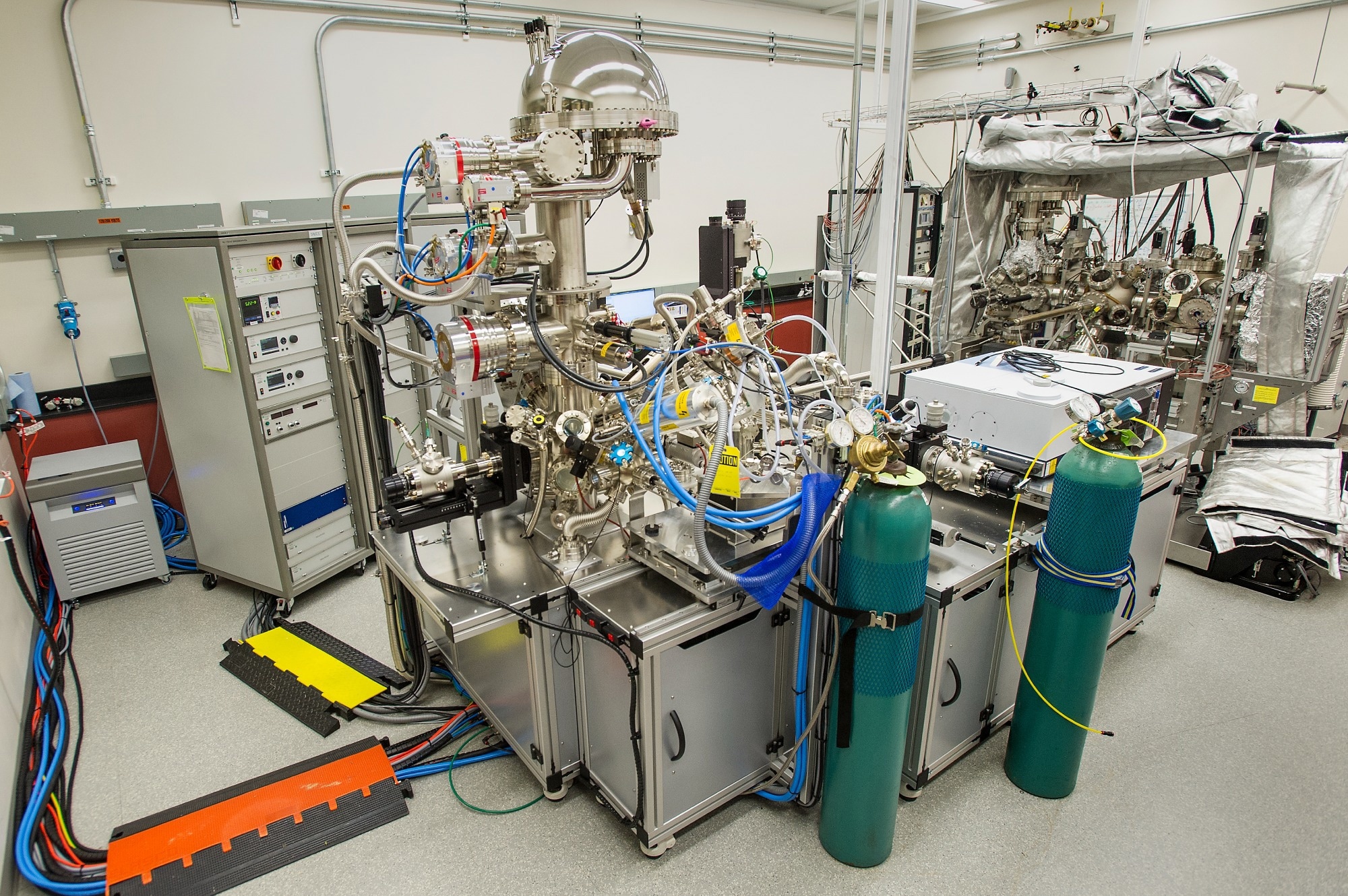

Lab Based Ambient Pressure X-Ray Photoelectron Spectroscopy (XPS) Instrument at CFN. Image Credit: Brookhaven National Laboratory.

They employed two complementary spectroscopy methods that had never been used in this way to see these rapid changes. The journal Proceedings of the National Academy of Sciences published the team's findings.

Copper is one of the most studied and relevant surfaces, both in catalysis and in corrosion science. So many mechanical parts that are used in industry are made of copper, so trying to understand this element of the corrosion processes is very important.

Anibal Boscoboinik, Materials Scientist, Center for Functional Nanomaterials

Ashley Head, a materials scientist at the Center for Functional Nanomaterials, added, “I have always liked looking at copper systems. They have such interesting properties and reactions, some of which are really striking.”

Researchers will have more control over the chemical reactions they generate, including potential renewable energy solutions, as a result of an improved understanding of oxide catalysts.

Controlling the amount of oxygen and the number of electrons on copper is crucial for effective chemical reactions since copper, for instance, can catalytically create and convert methanol into beneficial fuels.

Peroxide as a Proxy

Chemical compounds called peroxides have two oxygen atoms connected by shared electrons. Peroxides are very reactive due to the relatively weak link that makes it possible for other chemicals to change their structure.

In this experiment, the composition of peroxide species generated with several gases, including O2, H2, and CO, was determined to change the redox stages of catalytic oxidation processes on an oxidized copper surface (CuO).

Oxidation and reduction work together to form redox. The reducing agent loses an electron during this process, whereas the oxidizing agent obtains one. The researchers discovered that a surface layer of peroxide considerably improved CuO reducibility in favor of H2 oxidation when comparing these various peroxide species and how these procedures transpired.

On the other hand, they also discovered that it functioned as an inhibitor to prevent CO (carbon monoxide) oxidation from suppressing CuO reduction. They discovered that the peroxide’s opposite effect on the two oxidation processes results from the alteration of the surface locations where the reaction occurs.

By finding these bonding sites and understanding how they inhibit or promote oxidation, scientists can use these gases to gain more control over how these reactions play out. However, scientists needed a clear look at what was happening to tune these reactions.

The Right Tools for the Job

Due to peroxides’ high reactivity and how quickly these changes occur, the researchers felt it was crucial to study this reaction in its natural environment. On the surface, it is difficult to capture such a brief moment without the proper equipment or surroundings.

In-situ infrared (IR) spectroscopy has never detected peroxide species on copper surfaces before. Using this method, scientists examine how infrared radiation is absorbed or reflected under reaction circumstances to better understand a material's chemical characteristics.

In this experiment, researchers were able to distinguish “species” of peroxide that would have otherwise been exceedingly challenging to recognize on a metal oxide surface due to the slight changes in the oxygen they were carrying.

Head further stated, “I got really excited when I was looking up the infrared spectra of these peroxide species on a surface and seeing that there weren’t many publications. It was exciting that we could see these differences using a technique that’s not widely applied to these kinds of species.”

However, IR spectroscopy alone was not sufficient to be sure, so the researchers also utilized a different spectroscopy method called ambient pressure X-Ray photoelectron spectroscopy (XPS).

Lower energy X-Rays are used in XPS to force the sample’s electrons out. Scientists can learn more about the chemical characteristics of the atoms in the sample by examining the energy of these electrons. Having both techniques available through the CFN User Program was key to making this research possible.

Boscoboinik further stated, “One of the things that we pride ourselves in is the instruments that we have and modified here. Our instruments are connected, so users can move the sample in a controlled environment between these two techniques and study them in situ to get complementary information. In most other circumstances, a user would have to take the sample out to go to a different instrument, and that change of environment could alter its surface.”

Guangwen Zhou, professor at the Thomas J. Watson College of Engineering and Applied Science’s Department of Mechanical Engineering and the Materials Science program at Binghamton University, added, “A nice feature of CFN lies not only in its state-of-the-art facilities for science, but also the opportunities it provides to train young researchers. Each of the students involved have benefited from extensive, hands-on experience in the microscopy and spectroscopy tools available at CFN.”

Four Ph.D. students from Zhou’s lab, including the first co-authors of this study, Yaguang Zhu and Jianyu Wang, as well as Shyam Patel and Chaoran Li, contributed to this study. These students are just beginning their careers; they all received a Ph.D. in 2022.

Future Findings

The findings of this study could apply to different types of reactions and copper substitutes for catalysts. These findings and the processes and techniques that led researchers there could be applicable to other related research fields.

Metal oxides are frequently employed as catalysts or catalyst component materials. One technique to control surface reactions during other catalytic processes is by adjusting peroxide production on other oxides.

Head concluded, “I am involved in some other projects related to copper and copper oxides, including transforming carbon dioxide to methanol to use as a fuel for clean energy. Looking at these peroxides on the same surface that I use has the potential to make an impact on other projects using copper and other metal oxides.”

Journal Reference:

Zhu, Y., et al. (2023) Tuning the surface reactivity of oxides by peroxide species. Proceedings of the National Academy of Sciences. doi:10.1073/pnas.2215189120.