Solar power is a key player in reaching Net Zero.

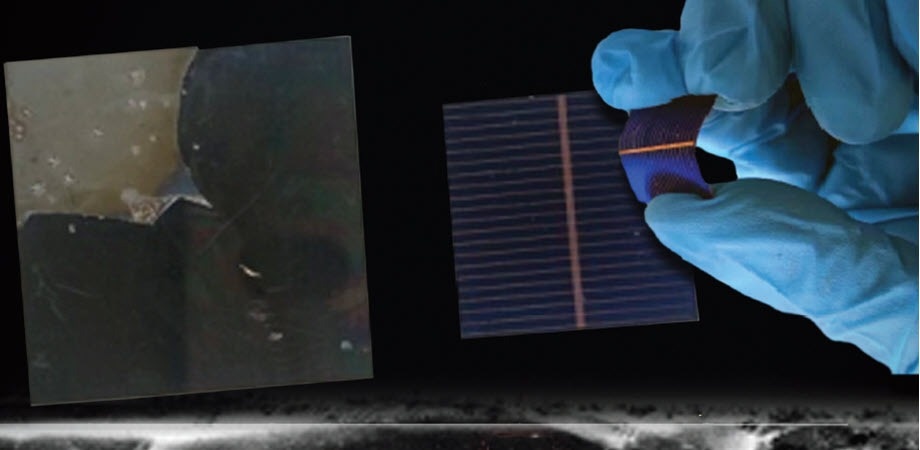

High-performance 20-μm-thin crystalline silicon (c-Si) solar cell design uses much less silicon. Figures from the report by Xie et al. include (left) a semi-finished c-Si cell on a flexible steel substrate; (middle) a complete cell; (right) an image of a fabricated thin c-Si cell showing its flexibility. Image Credit: doi.org/10.1117/1.JPE.13.035501

High-performance 20-μm-thin crystalline silicon (c-Si) solar cell design uses much less silicon. Figures from the report by Xie et al. include (left) a semi-finished c-Si cell on a flexible steel substrate; (middle) a complete cell; (right) an image of a fabricated thin c-Si cell showing its flexibility. Image Credit: doi.org/10.1117/1.JPE.13.035501

Currently, approximately 95% of solar cells in use rely on crystalline silicon (c-Si) as their primary material. Most conventional solar panel designs incorporate a c-Si photoactive layer with a thickness ranging from approximately 160 to 170 μm.

However, given that silicon accounts for nearly half of the total cost of each solar panel, experts are optimistic that the next generation of c-Si solar cells will be considerably thinner.

Regrettably, despite some recent advancements, the conversion efficiency of thin c-Si solar cells continues to lag significantly behind that of their thicker industrial counterparts.

This issue arises because the prevailing design strategies for thin c-Si cells are focused on optimizing individual parameters, such as short-circuit current density, open-circuit voltage, or fill factor. None of the existing methods can concurrently enhance all of these critical parameters necessary for achieving high efficiency.

In light of this context, a research team hailing from Hangzhou Dianzi University in China has devised a novel strategy poised to yield remarkable improvements in the efficiency of thin c-Si solar cells. Their groundbreaking study, recently published in the Journal of Photonics for Energy (JPE), marks a significant milestone in the realm of silicon solar cell technology.

The newly proposed strategy focuses on optimizing specific optical and electrical attributes, which the team has pinpointed as the culprits behind the differing conversion efficiencies observed in thick and thin c-Si solar cells.

Leveraging commercial software programs, they conducted optical simulations encompassing various designs for thin cells. Through subsequent experiments employing solar cells, the researchers formulated an innovative fabrication method that boasts several advantages over conventional approaches.

Instead of adhering to the conventional technique of cutting silicon ingots to produce thick c-Si layers, the team opted for a layer transfer method. They utilized hydrofluoric acid to create pores in a thick silicon wafer, resulting in a porous layer that served as a foundation for nurturing a slender 20-μm monocrystalline silicon layer. This thin layer could be easily detached and transferred onto a flexible stainless-steel substrate.

To enhance the optical and electrical capabilities of the thin silicon layer, the researchers applied multiple metal nanofilms to both sides through plasma-enhanced chemical vapor deposition. These included SiO2/SiNx/SiOx layers and Al2O3/SiNx/SiOx layers with a pyramidal texture on the sides facing the front and rear of the solar cell, respectively.

The front SiNx/SiOx and rear SiOx/SiNx layers amplified the silicon layer's light absorption, catering to shorter and longer wavelengths, respectively.

Consequently, this augmentation boosted the short-circuit current density, a metric denoting the quantity of charge carriers that the solar cell can generate and collect. Compared to a standard reference solar cell, the current density increased from 34.3 to 38.2 mA/cm2.

Moreover, the SiO2 and Al2O3 layers delivered robust surface passivation, minimizing recombination and the loss of generated charge carriers. This, in turn, resulted in a higher open-circuit voltage, representing the maximum voltage generated by a solar cell. It surged from 632 mV in the reference cell to 684 mV with the proposed design.

Consequently, the solar cell's fill factor, an indicator of its operational proximity to its theoretical maximum efficiency, escalated from 76.2 to 80.8 percent.

Both simulations and experimental data have corroborated that the proposed approach yielded a substantial improvement in conversion efficiency, increasing it from 16.5 to 21.1%.

This impressive enhancement amounts to a gain of 4.6%, equivalent to an approximate 28% improvement compared to the reference cell. Consequently, this elevates the efficiency of thin c-Si solar cells to a level closely approaching that of their industrial thick counterparts, which currently stands at 24%.

Overall, the findings of this study present a novel way to realize high-performance thin crystalline silicon solar cells using much less silicon—for a 20-μm cell, around one-eighth of the amount required for a thick 160-μm cell on a given panel size.

Leonidas Palilis, Professor,Condensed Matter Physics, University of Patras

Leonidas Palilis is also the Associate Editor of JPE.

This development is poised to play a significant role in promoting the broader and cost-effective adoption of silicon solar power technology. This is attributed to the reduced costs involved, which in turn, is expected to lead to an expansion in solar panel manufacturing capacity.

Journal Reference:

Xie, G., et al. (2023) Investigation on significant efficiency enhancement of thin crystalline silicon solar cells. Journal of Photonics for Energy. doi.org/10.1117/1.JPE.13.035501.