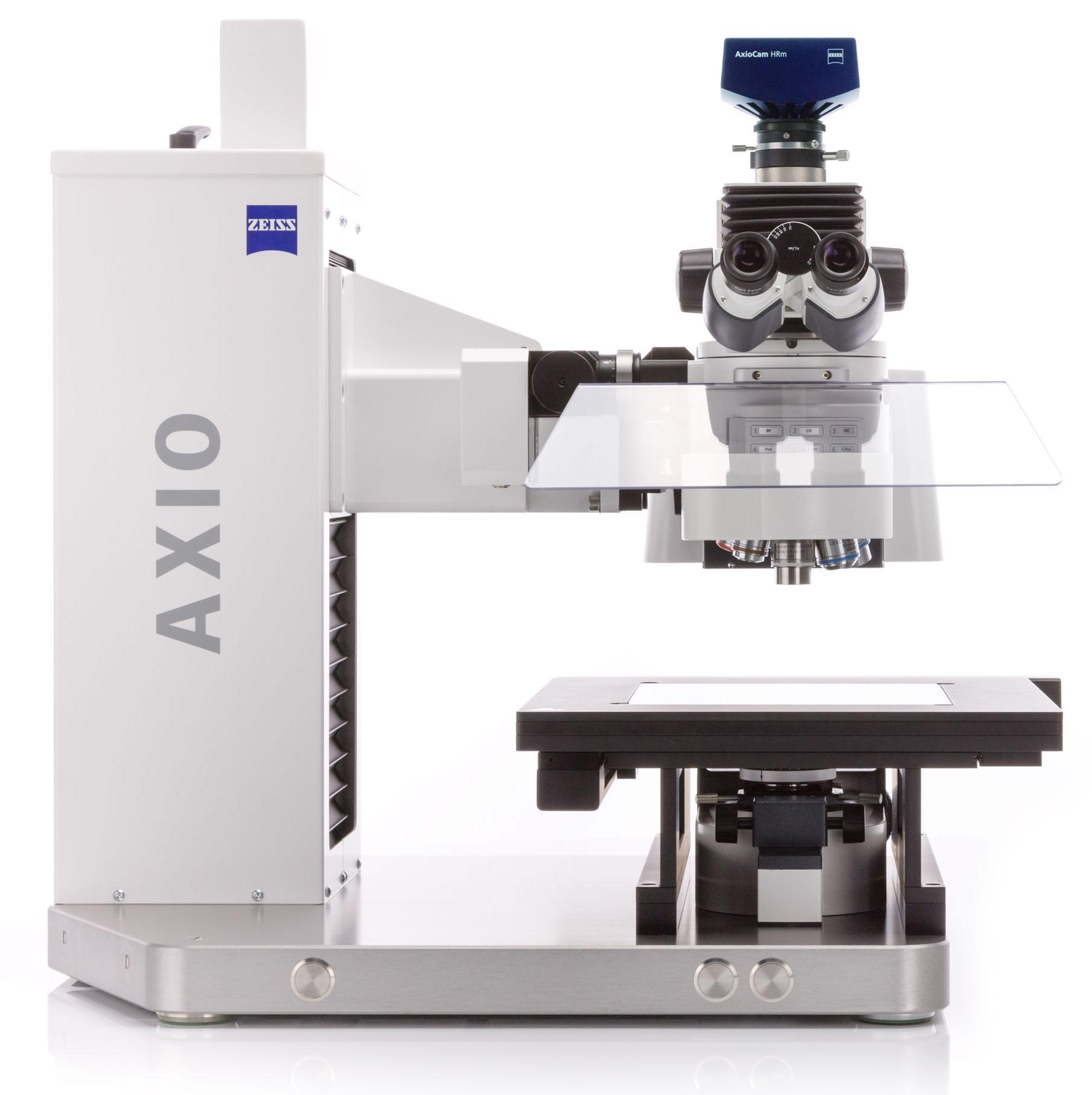

With the ZEISS Axio Imager Vario, users can examine the smallest MEMS sensors up to XXL wafer or even the complete flat planel panel displays without wrecking them.

Owing to the lateral space of up to 300 mm and sample height of up to 254 mm, users can scrutinize the widest variety of samples with the Axio Imager Vario. The column design provides high stability.

Users can have full control of their wafer in the clean room. A motorized z-drive along with the hardware autofocus guarantees the automatic setting of the perfect focus position.

Clean Room

The creation of semiconductors and examination of wafers can be done in clean rooms. Clean rooms are certified according to DIN EN ISO 14644-1, distinguished by the number and size of particles per m³.

The Axio Imager Vario is certified according to this protocol and matches the necessities of clean room class 5. Clean room class ISO 5 is the same as class 100 of the previous standard FED STD 209E (1992). The clean room kit with a 7x nosepiece turret, sneeze guard and particle protection are available.

Highlights

Image Credit: Carl Zeiss Microscopy GmbH

- Axio Imager Vario uses the nosepiece to focus on the sample. This means that users can realize repeatability and high focusing accuracy, particularly with heavy samples.

- With the Hardware Auto Focus, users profit from accurate, quick focusing of reflective samples, which are weak in contrast.

- Users can profit from the lateral sample space of up to 300 mm x 300 mm and the maximum sample height of up to 254 mm. They can choose between two manual and one motorized column with industry adhering three-button operation.

- Axio Imager Vario is certified according to DIN EN ISO 14644-1 and meets the needs of clean room class 5.

- Axio Imager Vario, along with LSM 700, will help users examine sensitive samples in high resolution without contact.