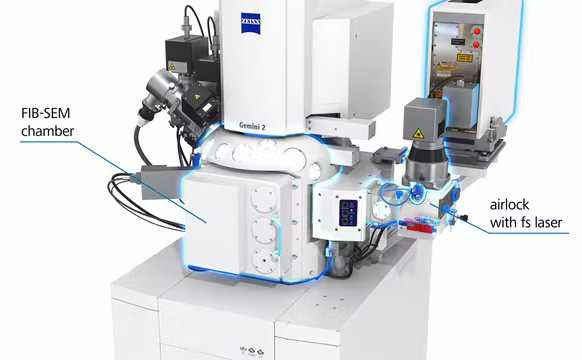

The new LaserFIB for ZEISS Crossbeam uses a femtosecond laser for ultrafast material processing of huge samples. Samples can be fabricated on a scale ranging from 10 µm to 1 mm or more. It is possible to cut deep cross-sections via tough materials like SiC and disclose structures of interest in a direct manner.

While executing laser milling, users will easily evade contamination of their FIB-SEM as the laser has been fixed to a steadfast chamber that is isolated from the primary instrument chamber.

With the help of the new LaserFIB for ZEISS Crossbeam, users can benefit from:

- Huge material removal: Make extremely big cross-sections, going up to millimeters in width and depth, within a few minutes (up to 15 mio. µm³/s)

- Minimal damage: As a result of the ultrashort laser pulses (femtosecond laser) in a steadfast chamber, damage and heat-affected zones remain minimal — without any contamination in the instrument

- Integrating laser and FIB: Gain quick access to deeply buried structures for concentrated ion beam scanning electron microscope (FIB-SEM) analysis and additional FIB machining

Image Credit: Carl Zeiss Microscopy GmbH

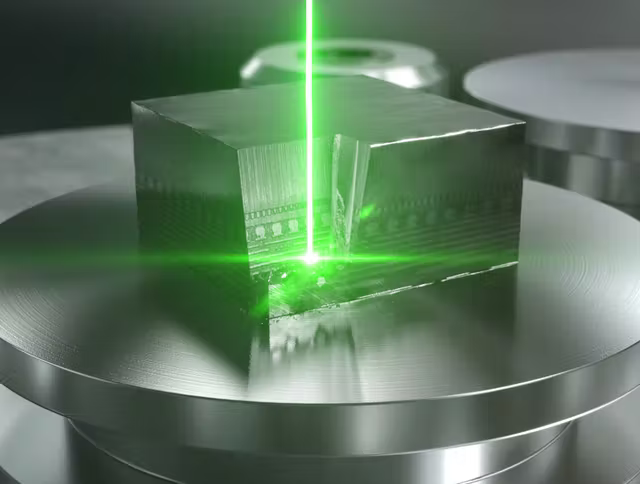

Massive Material Removal

Prepare Larger Samples in Less Time

The new LaserFIB for ZEISS Crossbeam is the perfect tool to make extremely huge cross-sections ranging up to millimeters in-depth and width within minutes. As a result of the ultrashort pulse duration of the femtosecond laser, LaserFIB achieves the greatest removal rates of up to 15 mio. µm³ per second.

Such high ablation rates are perfect to make samples for additional FIB machining with ZEISS Crossbeam, complementing LaserFIB with the greatest accuracy at an even smaller scale (100 nm to a few 10 µm).

Image Credit: Carl Zeiss Microscopy GmbH

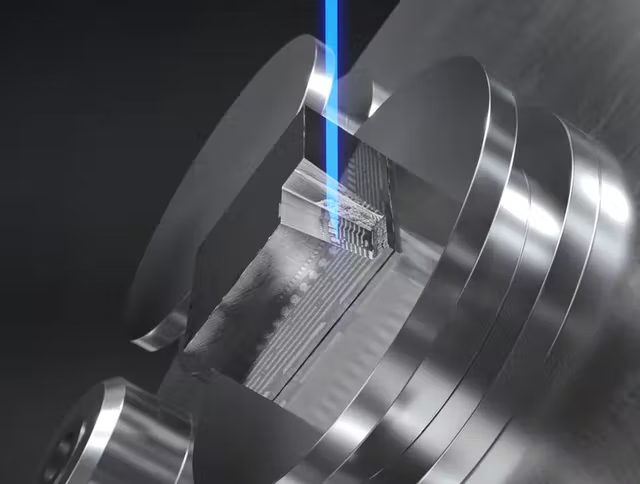

Combining Laser and FIB

Reveal All Structural Details

Disclose regions that are concealed under the surface directly, thereby disclosing all structural details in an extensive range of material types. If it is a hard or soft material, conducting or insulating material: LaserFIB machines sample at unparalleled speed.

Applications include the making of titanium alloy pillars for micromechanical testing or cube making in tungsten carbide.

Prior to laser processing, users can correlate their FIB-SEM reference image with 3D data, for example, X-Ray microscopy data. Following laser processing, return the sample to the primary FIB-SEM chamber for analysis. Execute final FIB polishing to disclose even more details.

Image Credit: Carl Zeiss Microscopy GmbH

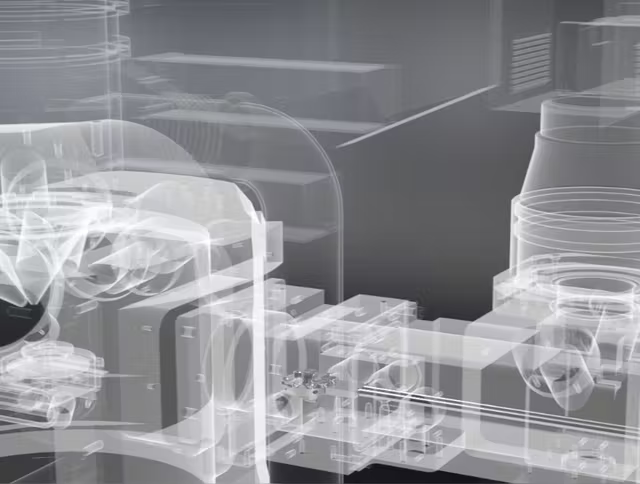

Minimal Damage

Conduct Quasi-Athermal Ablation

As a result of ultrashort laser pulses (femtosecond laser), LaserFIB leads to quasi-athermal ablation, thereby decreasing sample damage and keeping heat-affected zones to the minimum.

The laser work is performed in a dedicated chamber to prevent contamination and to allow safe and simple sample transfer between the laser chamber and the primary FIB-SEM chamber.

Image Credit: Carl Zeiss Microscopy GmbH