Smart Particle Investigator (SmartPI), an advanced particle analysis and classification solution, converts scanning electron microscopes into turnkey solutions for industrial cleanliness or metal and steel applications.

SmartPI integrates all features of image processing, SEM control, and elemental analysis (EDS) inside an individual application.

- Ability to control both SEM imaging and EDS analysis with one software program.

- Run automated and neglected particle analyses.

- Integrate SmartPI with ZEISS light microscope particle analysis solutions to structure a correlative workflow.

- SmartPI is flexible with ISO 16232 and VDA 19 cleanliness standards.

- Produce repeatable data and industry-standard compliant reports.

- Profit from the global ZEISS service and support for the complete system.

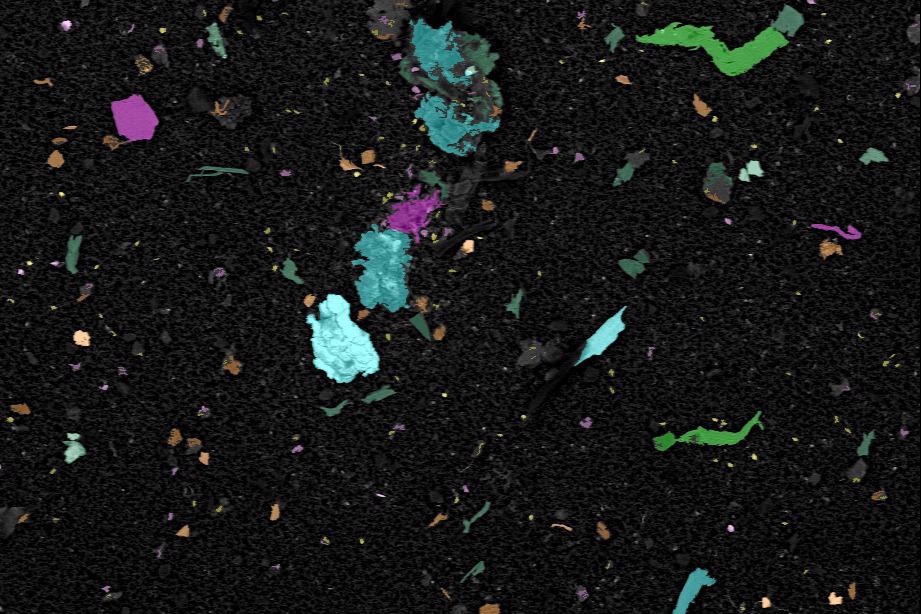

Energy dispersive X-ray (EDS) classification of particles. Image Credit: Carl Zeiss Microscopy GmbH

Advantages

Tailored Precisely to the Needs of Industry

SmartPI was made in close collaboration with an international supplier of automotive components, which had a particular need for strong yet user-friendly particle identification and classification system.

This implies that not only present industrial cleanliness analysis needs have been considered, but also usability concerns are fulfilled for the normal industrial surrounding, where not every operator is considered a microscopy expert, and when solutions are dispensed at multiple sites throughout the world.

The Power of Simplicity

SmartPI automation considerably eases operation so users do not have to be a microscopy expert to obtain great data. Simultaneously, highly experienced operators have the strength to easily make or alter recipes and customize the analysis routines to particular needs. All recipes, system configurations and particle data is stored in an auditable database for simple data review and export.

Intelligent Particle Detection

Using an advanced border particle stitching algorithm, SmartPI is also capable of detecting, characterizing and categorizing particles that are arranged throughout multiple fields of view, such as truncated particles inside the particle dataset.

This is specifically significant to guarantee that bigger particles are not dismissed from the statistics. It is an action that can be harmful to cleanliness or steel quality analysis.

A Fully Integrated Solution

With the help of one software program on a single PC, it is possible for users to control both SEM imaging and EDS analysis. ZEISS SmartPI keeps all data togther, guaranteeing both SEM and EDS data integrity and effective data recall.

Also, when the EDS system has been sourced from an EDS supplier, the full SmartPI system has been supported by the global ZEISS service and applications team—thereby keeping all customer care under one roof.

Example Filter. Image Credit: Carl Zeiss Microscopy GmbH

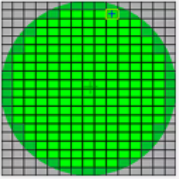

Analysis Start of Tiles. Image Credit: Carl Zeiss Microscopy GmbH

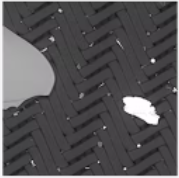

Image Acquisition. Image Credit: Carl Zeiss Microscopy GmbH

Feature Detection. Image Credit: Carl Zeiss Microscopy GmbH

Automated Segmentation. Image Credit: Carl Zeiss Microscopy GmbH

EDS Classification. Image Credit: Carl Zeiss Microscopy GmbH

Report. Image Credit: Carl Zeiss Microscopy GmbH

SmartPI at Work

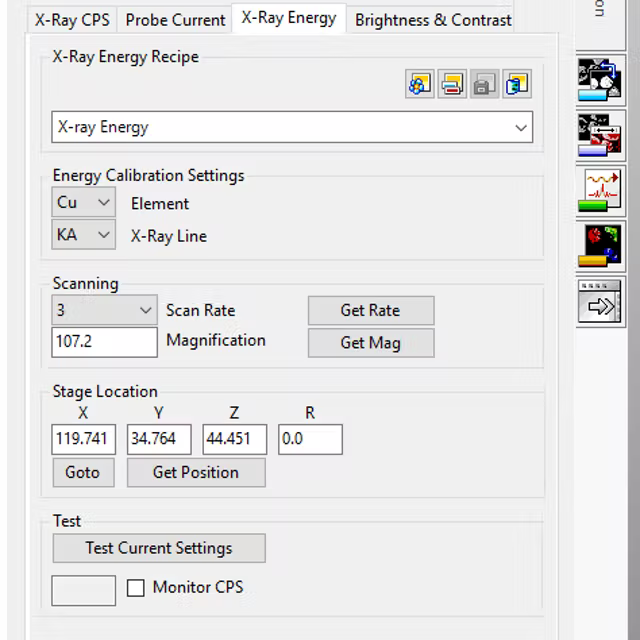

Auto-Calibration Procedures

SmartPI executes auto-calibration and self-diagnostic routines before each auto-run and during the run in a periodic manner. This guarantees system stability, precision and repeatable results.

Should an interruption take place during the auto-run, for instance when a filament replacement is needed, an auto-recovery process is initiated.

Energy calibration of EDS detector. Image Credit: Carl Zeiss Microscopy GmbH

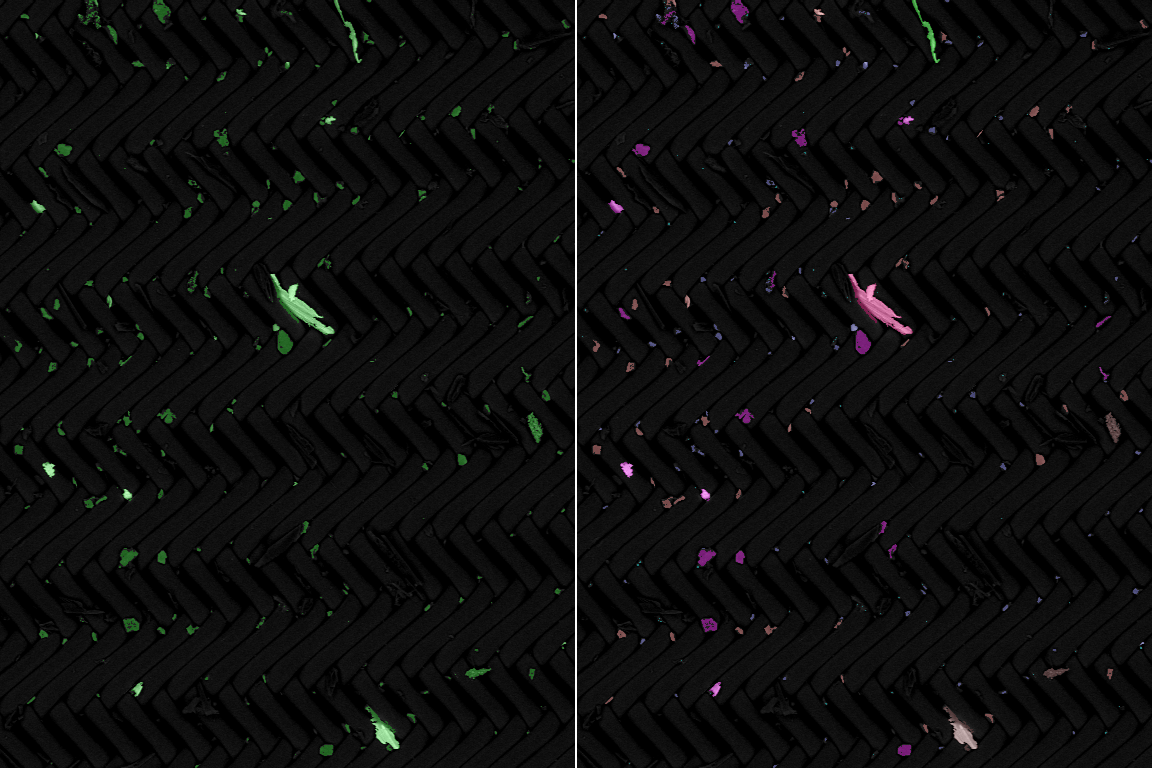

Morphological and Chemical Classification

SmartPI applies advanced image processing and analysis methods to quantify a range of morphological characteristics for every particle that has been detected. Later, EDS analysis is utilized to identify the chemical composition of every particle.

With the help of advanced ZEISS Feature Scan Mode, users can examine particles quickly with either Spot Mode or more elaborately. This scans the full particle shape to offer a more precise classification.

Morphological and Chemical Classification. Image Credit: Carl Zeiss Microscopy GmbH

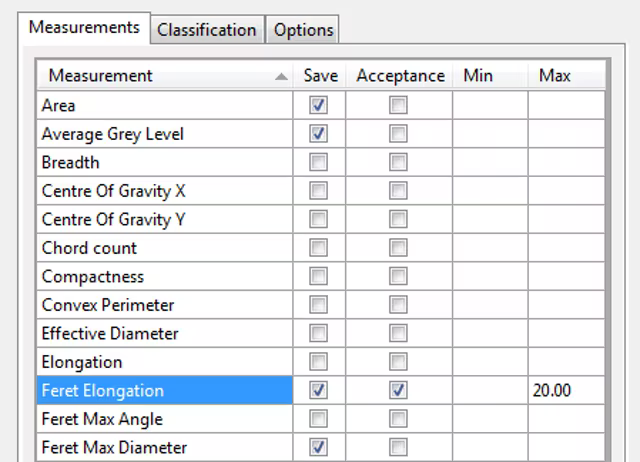

Measurement Exclusions

To ensure that users’ particle datasets are coherent and to reduce runtime, SmartPI allows users to eliminate particles that are not of interest, from consequent image and elemental analysis.

For example, this could be the case for extended fibers on the filter that might originate from dust in the surrounding, and hence are unconnected to particles originating from the manufacturing process.

Exclusion of fibers, for example, via limitation of the parameter elongation. Image Credit: Carl Zeiss Microscopy GmbH

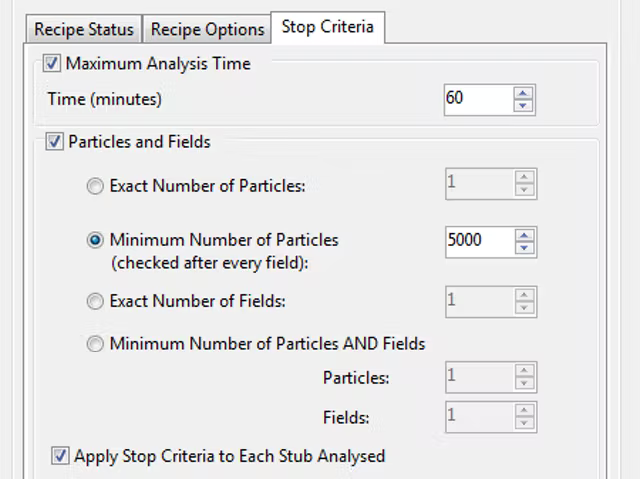

Advanced Stop Criteria

A variety of advanced stop criteria enables the auto-run to end the analysis when it obtains a predefined threshold. Stop criteria can consist of analysis time, particles’ or fields’ count, a specific categorization, particle size or other criteria that can be specified by the users.

This feature can be employed to single or multiple samples, thereby considerably decreasing the full run-time. Also, the live results window enables the operator to track the advance and decide if any intervention is needed.

Stop criteria setup page. Image Credit: Carl Zeiss Microscopy GmbH

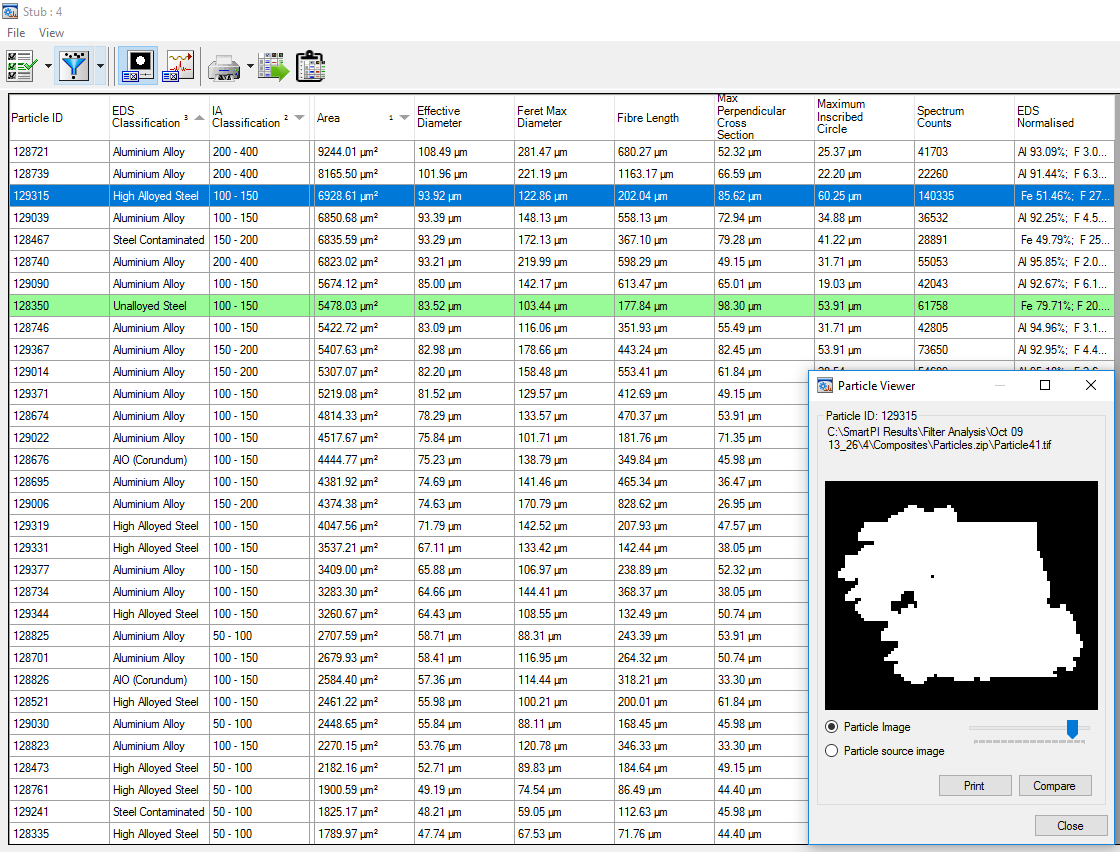

Interactive and Retrospective Particle Classification

Users can make use of the Review Output mode to refine and enhance the classification recipes by making an elaborate examination of the outcomes. Also, users can reconsider any particle by returning the stage to the suitable particle coordinates.

The Retrospective Analysis mode enables users to re-evaluate present outcomes with the help of new classification criteria. This does not require re-analyzing the sample.

Use the review mode to re-examine single particles and see all of their properties including EDS composition and material classification. Image Credit: Carl Zeiss Microscopy GmbH

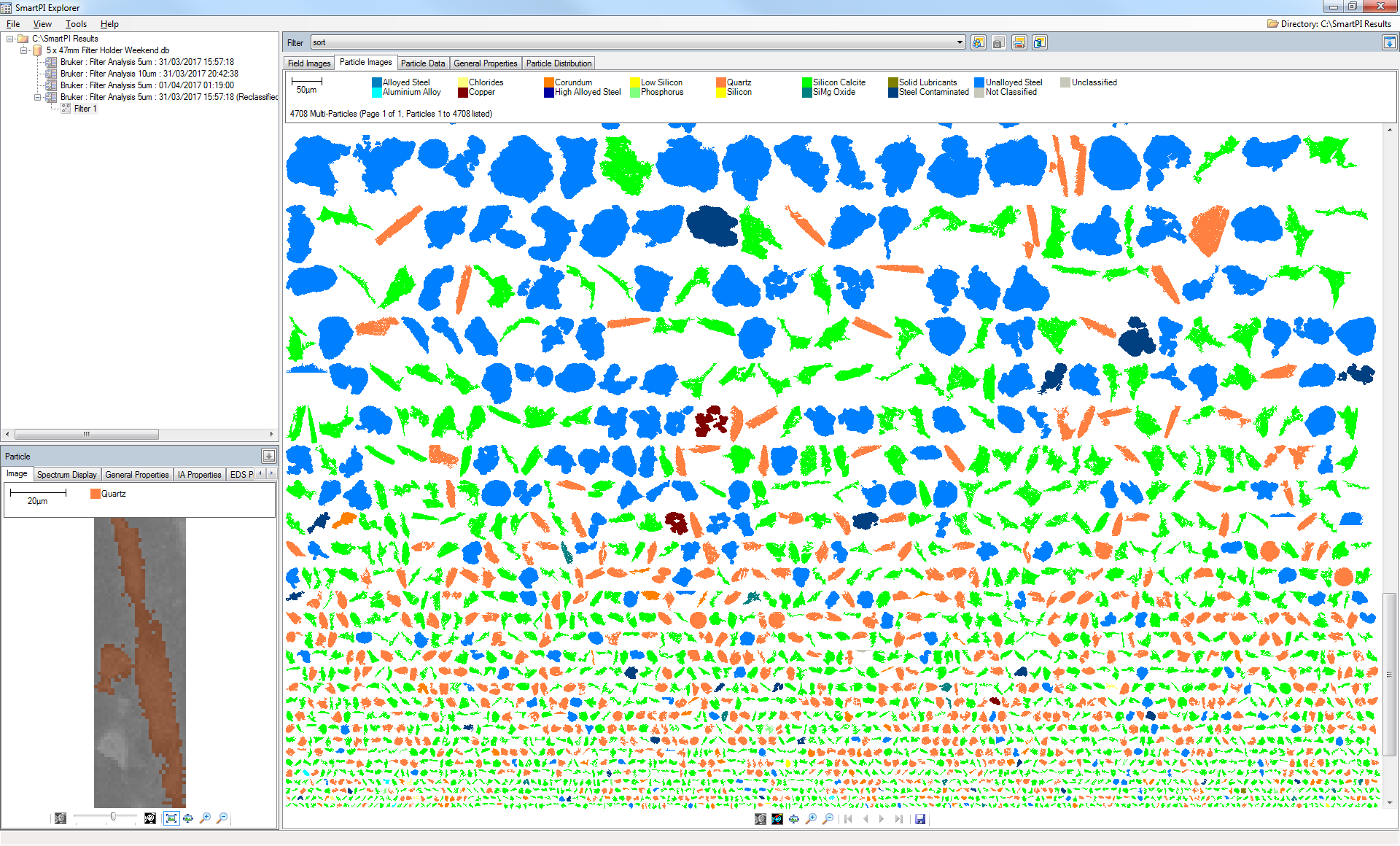

SmartPI Explorer

This standalone application lets the user browse or search the results for individual spectra, particle images, field images, border particles or other filters that users may select. In addition, SmartPI Explorer includes options for archiving, as well as an image montage feature for creating a stitched image from the fields analyzed. Explorer also may be used offline to free up system time for analysis.

SmartPI Explorer navigation window with multi-particle view. Image Credit: Carl Zeiss Microscopy GmbH

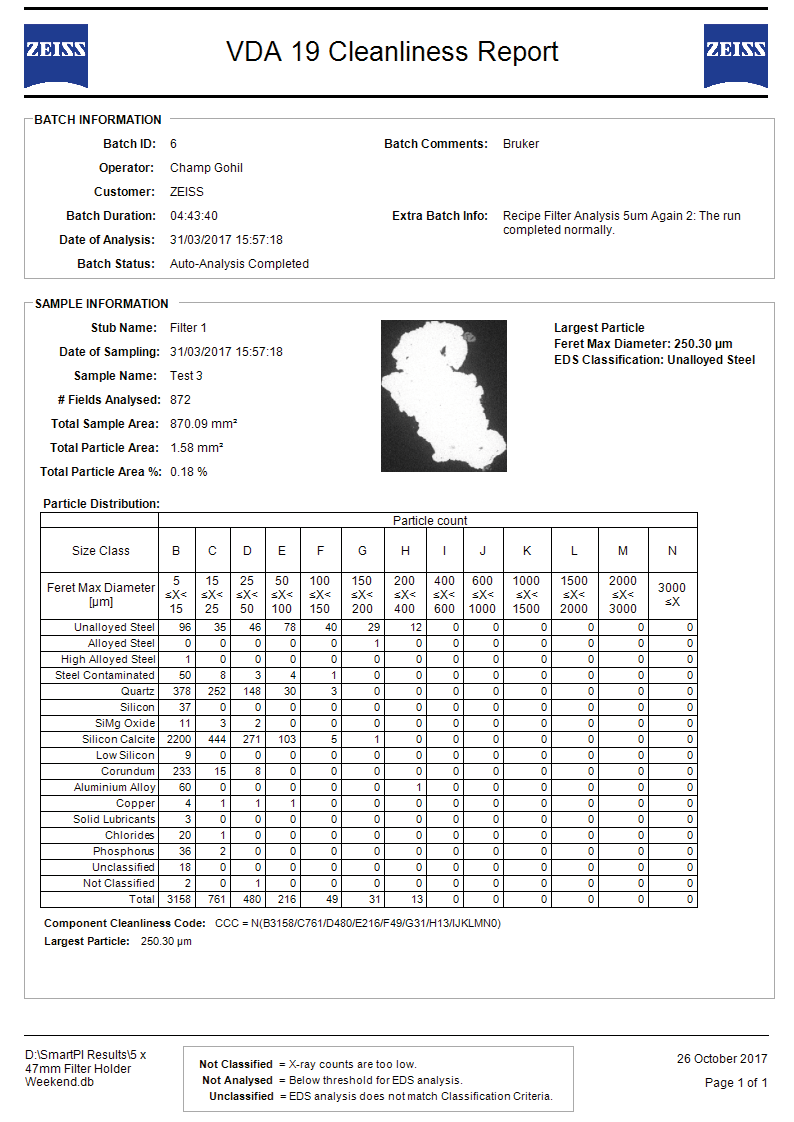

SmartPI Reporter

This independent application consists of various built-in tools enabling users to construct dedicated reports. Users can utilize drag-and-drop controls, alter a present report template, or choose an ISO or VDA standard report.

As soon as users have defined their report, they can save it as a template for additional reports. Utilize SmartPI Reporter online for immediate report generation or offline when users will be examining results later.

VDA 19 cleanliness report generated in SmartPI Reporter. Image Credit: Carl Zeiss Microscopy GmbH

Recommended SEM Platforms

EVO

Scanning Electron Microscope

EVO is the conventional SEM of choice for use in regular materials analysis or industrial quality assurance and failure examination. EVO provides a highly configurable imaging platform available for particle analysis applications with the help of a huge motorized 5 axis stage, and user-friendly SmartSEM software.

EVO comes with variable pressure (VP), thereby allowing the imaging and analysis of non-conductive samples, like filters, without the requirement to apply a conductive coating, hence leaving the filter intact for consequent analysis using, for example, FTIR or Raman.

Image Credit: Carl Zeiss Microscopy GmbH

Sigma

Field Emission Scanning Electron Microscope

Sigma is the SEM of choice for users who are in need of enhanced resolution for particle analysis in the nanometer scale range. Sigma, featuring Gemini column technology, offers excellent imaging and analytical outcomes from a field emission scanning electron microscope (FE-SEM).

The Gemini optics offers the greatest resolution imaging on a platform very well adapted for elemental analysis. This is done especially for magnetic samples.

Image Credit: Carl Zeiss Microscopy GmbH