Jan 7 2011

Michael Kessler has worked with polymers that repair themselves when they crack.

And he's worked with polymers made from vegetable oils. Now he's working to combine the two technologies.

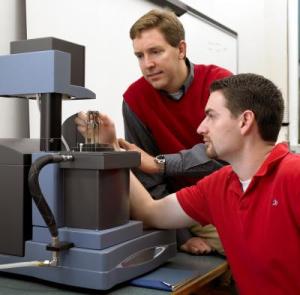

Michael Kessler, left, and former Iowa State doctoral student Will Goertzen use a dynamic mechanical analyzer to measure the mechanical properties of polymers.

Michael Kessler, left, and former Iowa State doctoral student Will Goertzen use a dynamic mechanical analyzer to measure the mechanical properties of polymers.

Kessler, an Iowa State University associate professor of materials science and engineering and an associate of the U.S. Department of Energy's Ames Laboratory, is researching and developing biorenewable polymers capable of healing themselves as they degrade and crack.

"If successful, the results of this research will provide biorenewable alternatives to petroleum-based resins," says a summary of Kessler's research project. Successfully developing the concept "should have a huge impact economically and environmentally."

Kessler's research project is supported by a five-year, $400,000 grant from the National Science Foundation's Faculty Early Career Development Program.

Kessler started working with self-healing materials as a doctoral student at the University of Illinois at Urbana-Champaign. He was part of a research team that in February 2001 published an article in the journal Nature that helped launch the field.

The technology has evolved into a system that embeds catalysts and microcapsules containing a liquid healing agent within a composite. As cracks develop in the composite, they rupture the microcapsules and release the healing agent. The healing agent contacts the catalyst and reacts by forming 3-D polymer chains that fill the cracks. That increases material lifetimes and reduces maintenance.

Visit his office, and Kessler will pull out a little container half filled with what looks like fine yellow powder. Those are the hollow microcapsules that make the self-healing process work, he said. (They're also the same technology behind scratch-and-sniff perfume ads.)

When Kessler joined Iowa State and the Ames Laboratory in 2005, he started working with Richard Larock, a Distinguished Professor of Chemistry and associate of the Ames Laboratory, to develop biorenewable polymers from vegetable oils.

Larock has invented and patented a process for producing various bioplastics from inexpensive natural oils, which make up 40 percent to 80 percent of the plastics. Larock has said the plastics have excellent thermal and mechanical properties and are very good at dampening noises and vibrations. They're also very good at returning to their original shapes when they're heated.

But can they be developed into a self-healing material?

Early results show there's laboratory work to do. Kessler's research has found that a healing agent for a polymer based on tung oil works too fast. Kessler and Peter Hondred, an Iowa State graduate student in materials science and engineering, are working to slow the agent for better healing.

The researchers are also working to develop encapsulating techniques that work with biorenewable polymers. And they're working to develop bio-based healing agents.

Despite the challenges, Kessler thinks there is potential to develop self-healing, biorenewable materials. He said the big question is whether researchers can push the healing efficiency of biorenewable polymers close to the 90 percent of standard composites.