A research team at UCLA has developed a novel process for making highly conductive, flexible, transparent electrodes utilizing silver nanowires and other nanomaterials.

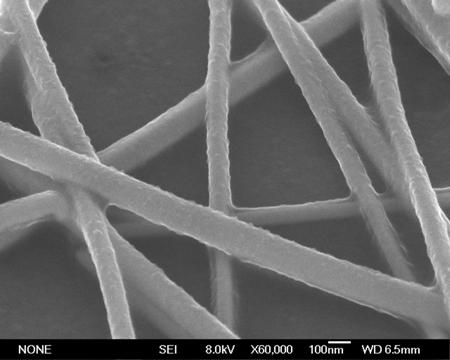

This scanning-electron micrograph shows a transparent conducting film made up of silver nanowires (apparent as lines), titanium nanoparticles and a conductive polymer. (Photo courtesy of UCLA)

This scanning-electron micrograph shows a transparent conducting film made up of silver nanowires (apparent as lines), titanium nanoparticles and a conductive polymer. (Photo courtesy of UCLA)

Due to its flexibility and high conductivity, silver nanowire networks have been often considered as an ideal replacement for indium tin oxide (ITO). However, it requires complicated processes to fuse cross it to obtain better substrate adhesion and low resistance. To tackle this issue, the UCLA scientists have fused the silver nanowires with organic polymers and metal oxide nanoparticles to make conductors with high-transparency.

Nanoparticles can be used for the production of a transparent mat by simply spraying them over a surface. However, the difficulty involved is to stick the siliver nanowires onto the surface without using high pressures or high temperatures, which can reduce their compatibility with the sensitive organic materials normally utilized in the production of flexible electronics.

To address this issue, the research team has devised a low-temperature process to manufacture the novel silver nanowire electrodes utilizing spray coating of a special mixture of nanomaterials. The team firstly sprayed a silver nanowire solution onto the surface and then a titanium dioxide nanoparticle solution is used to treat the nanowires to produce a hybrid film. When the film dries, the nanowires get drawn together due to capillary forces, enhancing the conductivity of the film. The team then coated a conductive polymer layer over the film to improve the adhesion of the wires to the surface.

The resulting silver nanowire composite meshes have superior mechanical properties and optical transparency. The research team used the novel electrodes to develop solar cells with a performance equivalent to that of ITO-based solar cells.