Materials scientists from MIT and Boston College are developing a novel nanotechnology design to increase the electrical conductivity of a bulk alloy semiconductor such as Silicon Germanium (SiGe) by 30 to 40%.

While long valued for high-temperature applications, the bulk alloy semiconductor SiGe hasn't lent itself to broader adoption because of its low thermoelectric performance and the high cost of Germanium. A novel nanotechnology design created by researchers from Boston College and MIT has shown a 30 to 40 percent increase in thermoelectric performance and reduced the amount of costly Germanium.

While long valued for high-temperature applications, the bulk alloy semiconductor SiGe hasn't lent itself to broader adoption because of its low thermoelectric performance and the high cost of Germanium. A novel nanotechnology design created by researchers from Boston College and MIT has shown a 30 to 40 percent increase in thermoelectric performance and reduced the amount of costly Germanium.

The bulk SiGedelivers high performance when used in high-temperature thermoelectric applications, including radioisotope thermoelectric generators utilized on NASA flight programs. However, wider applications of the material are limited due to its low thermoelectric performance and the increased cost of Germanium.

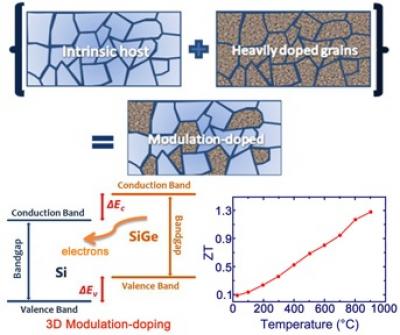

The researchers have demonstrated that they were able to boost the electrical conductivity of the bulk alloy semiconductor by over 50% by changing the design of the material using a 3D modulation-doping strategy process, which is commonly used in the thin-film semiconductor industry. The 3D process succeeded in developing a solid-state device with a high figure of merit of approximately 1.3 at 900 °C.

Bo Yu, graduate researcher at Boston College, stated that improving the figure of merit of a material is very challenging as all the internal factors are closely associated with each other. If one factor is changed, then the other may also change, which leads to no improvement of the material’s performance. Hence, researchers are looking for new opportunities or developing of new material systems in this field.

The new design that is developed by MIT and Boston College researchers needs 30% less Germanium compared to the standard design of the n-type SiGe alloy materials. Thus, the total cost required for fabrication of the material is lowered, which is critical for innovative clean energy technologies. ZhifengRen, professor of physics at Boston College, remarked that they focus on removing cost barriers of all the materials that are being studied by them. The current research work receives funding support from the Solid State Solar Thermal Energy Conversion Center.