Aug 22 2016

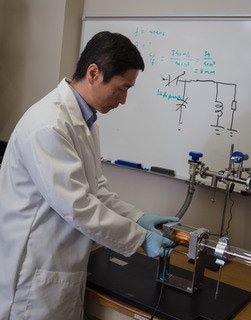

Qi Hua Fan, associate professor of electrical engineering and computer science, is developing new electro-optical materials using this plasma processing equipment. (Credit: South Dakota State University)

Qi Hua Fan, associate professor of electrical engineering and computer science, is developing new electro-optical materials using this plasma processing equipment. (Credit: South Dakota State University)

Biochar is a cost-effective material is rich in carbon, and has been used by two SDSU engineering researchers to develop the porous surface required to capture electricity. This new technique of developing a porous surface will help to reduce the cost of supercapacitors.

According to explainthatstuff.com, supercapacitors play a vital part in energy harvesting systems like regenerative braking systems of hybrid vehicles, because they can absorb and discharge energy in a rapid manner. However, supercapacitors are costly.

Materials Today reported that, about half the materials cost is due to activated carbon that is used to coat the electrodes. Activated carbon that is of the supercapacitor-grade can cost up to $15 per kilogram.

Plasma etching is adopted by associate professor of electrical engineering and computer science, Qi Hua Fan, to activate the biochar. The activated biochar is then used by associate professor Zhengrong Gu of agricultural and biosystems engineering to produce supercapacitors. Biochar is obtained as a byproduct of the pyrolysis process in which plant materials are converted into biofuel.

Activating Biochar

Raw biochar needs activation to create the porous structure needed to trap ions.

Qi Hua Fan, Associate Professor, SDSU

Generally, a chemical activation process requires a chemical catalyst, and a high temperature of about 1,700°F for two hours, after which it is exposed to chemical washing and drying for a long time period. As a result, it becomes an energy-intensive and time-consuming procedure.

Biochar that is similar to charcoal can be produced from crop residues like corn stover, dried distillers grain with solubles (known as DDGS) or wood. In this research, however, Fan has made use of biochar that is commercially available and that is made from yellow pine.

A number of research groups have previously studied the specific performance and capacitance of this kind of biochar, he said, “So we had a baseline.” Additionally, the quantities of biochar required to ensure that test results are repeatable could be supplied by a company.

To perform plasma etching, oxygen was applied and excited by the usage of radio frequency via a dielectric barrier discharge. Fan then handed over the activated biochar to Gu, who later developed supercapacitors. A five-month, proof-of-concept grant from the North Central Regional Sun Grant Center supported the research work. Two graduate students were also involved in this project work.

Increasing Capacitance, Improving Efficiency

When a comparative study of capacitor performances was conducted by researchers, they found that capacitors developed using plasma treatment showcased 1.7 times higher specific capacitance (171.4 Farads), while capacitors developed using chemical activation produced only 99.5 Farads. “That’s a big improvement,” Fan pointed out.

Without external heating or any chemicals, the process took only 15 minutes.

It is very fast and consumes very little energy. The energy required to activate biochar is equivalent to what we use for a light bulb.

Qi Hua Fan, Associate Professor, SDSU

In a research paper presented in the Journal of Power Sources, Fan, Gu and assistant physics professor Parashu Kharel explain, “oxygen plasma was capable of creating various pore sizes that would allow easy access for the electrolyte ions to the porous surface, leading to a higher capacitance than the chemically activated biochar.”

Further, oxygen plasma-activated capacitors had low estimated resistance of 3.3Ω, whereas chemically treated capacitors had a resistance of 14.5Ω. This was because of the ions that have easier access to the mesopores and micropores that are developed by plasma processing.

And, Fan added, “Yellow pine is not the best biochar for supercapacitors.” He wishes to see similar enhancement in performance when using biochar obtained from a variety of biomass types.

However, he wants the process to be boosted for each type of structure. “Activation depends on what kind of plasma, what conditions are used and how long we treat the material.”

A patent application has been filed by Fan for the plasma activation process developed by him. His next step will be to apply for funding in order to expand this promising plasma processing technique for other kinds of biochar.

“No matter what kind of parameters we eventually end up with, this will be very efficient,” he added.