May 5 2017

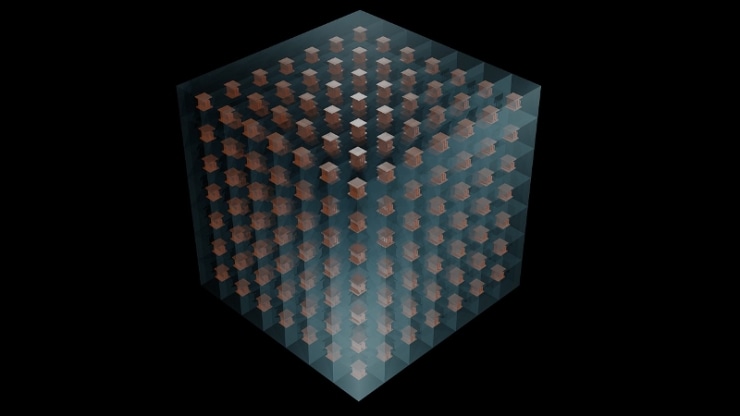

An illustration of how 3-D-printed metamaterial unit cells could be combined like Lego blocks to create structures that bend or focus microwave radiation more powerfully than any material found in nature. Credit: Abel Yangbo Xie, Duke University

An illustration of how 3-D-printed metamaterial unit cells could be combined like Lego blocks to create structures that bend or focus microwave radiation more powerfully than any material found in nature. Credit: Abel Yangbo Xie, Duke University

Duke University researchers have used an electrically conductive material compatible with a standard 3D printer to 3D print potent electromagnetic metamaterials.

The demonstration could bring about a revolution to the rapid design and prototyping of radio frequency applications such as Wi-Fi, Bluetooth, wireless sensing and communications devices.

Metamaterials are synthetic materials made up of many individual, engineered devices called cells that together develop properties that cannot be found in nature. As an electromagnetic wave travels through the metamaterial, the wave gets manipulated by each engineered cell in a particular way in order to dictate how the wave behaves as a whole.

It is possible to customize metamaterials in order to have unnatural properties such as perfectly absorbing specific wavelengths of light, focusing electromagnetic waves onto multiple areas and bending light backwards. However, previous efforts have been constrained to 2D circuit boards, bringing about limitations in their abilities and effectiveness and making their fabrication difficult.

Duke materials scientists and chemists, in a new paper appearing online in the journal Applied Physics Letters, have demonstrated a way that will help bring electromagnetic metamaterials into the third dimension using common 3D printers.

There are a lot of complicated 3-D metamaterial structures that people have imagined, designed and made in small numbers to prove they could work. The challenge in transitioning to these more complicated designs has been the manufacturing process. With the ability to do this on a common 3-D printer, anyone can build and test a potential prototype in a matter of hours with relatively little cost.

Professor Steve Cummer, Electrical and Computer Engineering, Duke

Finding the perfect conductive material to run through a commercial 3D printer plays a vital role in making 3D printed electromagnetic metamaterials a reality. Usually, such printers use plastics, which are typically considered to be poor at conducting electricity.

A few commercially available solutions are available that mix metals in with the plastics, but none are conductive enough to produce viable electromagnetic metamaterials. Even though metal 3D printers are available, they cost almost $1 million and occupy one full room.

It is at this point that Benjamin Wiley, Duke associate professor of chemistry, enters.

Our group is really good at making conductive materials. We saw this gap and realized there was a huge unexplored space to be filled and thought we had the experience and knowledge to give it a shot.

Benjamin Wiley, Associate Professor, Chemistry, Duke

A 3D printable material, 100 times more conductive than anything currently on the market, was developed by Wiley and Shengrong Ye, a postdoctoral researcher in his group. This material is presently being sold under the brand name Electrifi by Multi3D LLC, a startup discovered by Wiley and Ye. Even though it is still not close to being as conductive as regular copper, Cummer believed that that it might just be conductive enough to develop a 3D printed electromagnetic metamaterial.

Cummer and doctoral student Abel Yangbo Xie, in a paper, demonstrated that Electrifi is not only conductive enough but that it also interacts with radio waves almost as strongly as standard metamaterials developed from pure copper. That small difference is easily made up for by the printed metamaterials’ 3D geometry and the results highlight that the 3D printed metamaterial cubes interact with electromagnetic waves 14 times in a much better manner than their 2D counterparts.

Researchers can start building new devices by printing numerous cubes, each customized to specifically interact with an electromagnetic wave in a particular way, and then joining them like Lego building blocks. However, for the devices to work, it is essential for the electromagnetic waves to be roughly the same size as the individual blocks. Besides ruling out the visible spectrum, infrared and X-rays, this also leaves open a wide design space in microwaves and radio waves.

“We’re now starting to get more aggressive with our metamaterial designs to see how much complexity we can build and how much that might improve performance,” said Cummer. “Many previous designs were complicated to make in large samples. You could do it for a scientific paper once just to show it worked, but you’d never want to do it again. This makes it a lot easier. Everything is on the table now.”

We think this could change how the radio frequency industry prototypes new devices in the same way that 3-D printers changed plastic-based designs. When you can hand off your designs to other people or exactly copy what somebody else has done in a matter of hours, that really speeds up the design process.

Benjamin Wiley, Associate Professor, Chemistry, Duke

A Multidisciplinary University Research Initiative grant from the Office of Naval Research (N00014-13-1-0631) supported this work.