May 23 2017

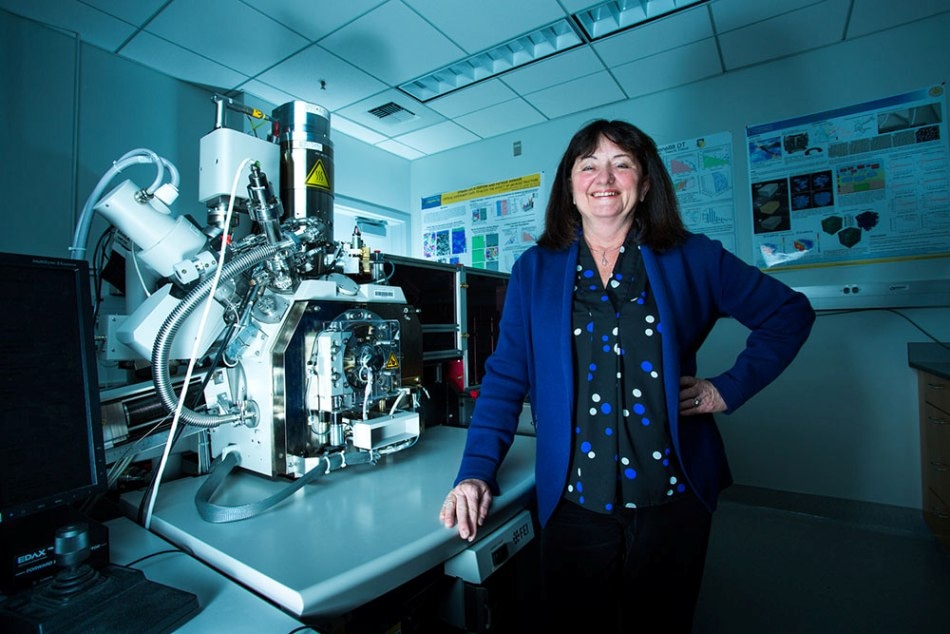

Tresa Pollock stands next to an electron microscope linked to a custom-made table mounted with a chamber used for advanced 3-D printing. (Photo Credit: MATT PERKO)

Tresa Pollock stands next to an electron microscope linked to a custom-made table mounted with a chamber used for advanced 3-D printing. (Photo Credit: MATT PERKO)

On its return trip from the cosmos, the Space Shuttle was traveling at 17,000 miles per hour— 25 times the speed of sound. If it were not for the ceramic tiles that served as heat shields, the whole spacecraft would have burned to nothing before it reached Earth.

Those are some extreme conditions.

And those are precisely the kinds of the conditions UC Santa Barbara scientist Tresa Pollock frequently has in mind as she aims to discover new and better materials.

Recently, Pollock, chair of the materials department at UCSB, has been bestowed one of 13 prestigious 2017 Vannevar Bush Faculty Fellowships from the U.S. Department of Defense (DoD). The award includes $3 million to fund Pollock’s research for five years, which is aimed at creating a 3D platform for discovering new materials capable of functioning in extreme environments such as those experienced by rockets, hypersonic flight vehicles, and aircraft engines.

The fellowship program bestows awards to leading scientists from U.S. universities to conduct ground-breaking “high risk, high pay-off” research that looks into the “hard” problems that DoD needs to solve.

I am very honored to be selected for this award, which is named after a visionary scientist who shaped the U.S. research infrastructure. I am also grateful for the research support this provides and for the support the DoD has provided for many of my previous research efforts. The Vannevar Bush Fellowship will allow us to pursue research in directions not possible with other types of research programs.

Tresa Pollock, Scientist, UC Santa Barbara

Said Rod Alferness, dean of UCSB’s College of Engineering: “For Tresa Pollock to receive a prestigious Vannever Bush Award from the U.S. Department of Defense is a tremendous and well-deserved honor. I have no doubt that the funding that comes with the fellowship will enable her and her team to develop breakthroughs in 3D printing, nanoscale analysis and efficient production of important new materials.”

Printing advanced materials into complex architectures on demand poses many technical challenges, and this fellowship will enable us to tackle what are currently limiting materials-science issues. The award builds on our previous research on crystal growth and solidification, 3D materials science and alloy design. These intellectually challenging areas of research are highly suited to the talented Ph.D. students at UCSB.

Tresa Pollock, Scientist, UC Santa Barbara

In recent years, it has become possible to use both electron and laser beams to “print” engineering objects that have intricate shapes. The process requires melting and fusing metallic powder particles — each around 10 times finer than a grain of beach sand — in millimeter-scale “pools” formed by local focusing of an electron or laser beam.

Drawing from the whole periodic table, it would be possible to blend and print millions of metallic powders having varying combinations of elements. But so far, Pollock clarified, it has been possible to print with just six or seven types of powders. More information is required, she said, regarding the complex series of events that happen during the melting, blending, and vaporization of the material that occur when the powder bed is scanned by a high-intensity beam, and subsequently as the material cools.

The grand challenges for making materials in this fashion are twofold and three-dimensional. We need to design material compositions in which defects will not form during melting and cooling within the cubic-millimeter pool, and we need 3-D tools to examine the structure of that millimeter-scale volume of material at the nanometer scale to ensure that the structure is sound. The Vannevar Bush fellowship will enable us to focus on these two aspects of the printing problem.

Tresa Pollock, Scientist, UC Santa Barbara

Based on a combined electron and laser-beam tomography system she designed at UCSB, Pollock will develop and integrate an extra open-source, highly automated laser-powder-processing platform that can be worked either in layer-by-layer additive build mode for a particular material, or in combinatorial chemistry mode to differ chemistry locally.

According to Pollock, the 3D platform will allow study of formerly inaccessible design spaces of higher-dimensional compositional materials and will also enable quick acquisition of 3D information about the materials’ structure, chemistry, and crystallography — from the nanometer-to-millimeter length scales that are important in emerging approaches to additive manufacturing.