For nanocomposite modification, differently doped nano-SiO2 are introduced into polyimide by researchers as per the latest paper published in the journal Polymers. The findings of measuring the lifespan of excellent voltage stress with discharging reveal that 10% SiO2 doping has the longest lifetime.

Study: Study on High-Frequency Surface Discharge Characteristics of SiO2 Modified Polyimide Film. Image Credit: RHJPhtotoandilustration/Shutterstock.com

Importance of Polyimide

Polyimide (PI), one of the finest shielding organic substances, is frequently utilized for high-Frequency Power Transformer (HFPT) inter-turn insulation. In 1964, polyimide film was introduced commercially as an excellent industrial electrical shielding. Aeronautical engineers rapidly saw the potential for the area and robust design with this thermal and radioactivity defensive response and used it into early concepts of irradiation shielding and insulation materials wrap.

Polyimide material is commonly utilized as a platform in adaptable printed circuit boards in the semiconductor industry due to its resilience to operating temperature and solvents. Thermally stable polyimide film provided engineers with superior physical durability, exceptional dielectric properties, better thermal performance qualities, and the capability to adapt closely to edges, reducing airflow capture.

Need for Study of High-Frequency Creeping Discharge

The high-frequency sine wave within the HFPT will worsen the epidermis impact and proximity effect of the magnetic core within the gadget, resulting in considerable dielectric degradation and thermal gain. At the same time, because the thermal runaway flux density over the interface is substantially lower than the air gap collapse amplitude of the same gap, creeping discharge is more likely to develop at the HFPT tip failure, finally leading to insulation system failure. As a result, it is critical to investigate the high-frequency creeping outflow of polyimide.

Advantages and Limitations of Modifications of Polyimides

Polyimide nanofiber reconfiguration can considerably enhance its properties such as corona impedance, thermal resistance, and the impurity of silicon-containing particulate in polyimide can enhance the substance's extensive activities such as anti-oxygen effectiveness and insulating characteristics.

However, there is a scarcity of information on HFPT insulation, that is, the development strategy and qualities of high frequency creeping discharge of polyimide film under grossly imbalanced fields, particularly after the polyimide is altered by nanostructure with SiO2.

The most recent study employed in-situ processing to create customized polyimide sheets loaded with nanoparticles of SiO2 with 2%, 4%, 6%, 8%, and 10% molar content of Si. First, the high-frequency creeping discharge life was evaluated, followed by the longest-life modified film and pure polyimide film.

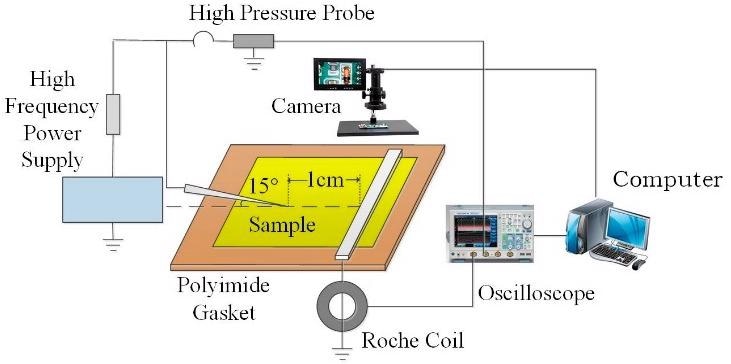

High frequency creeping discharge platform. Image Credit: Xing, Z. et al., Polymers

Research Findings

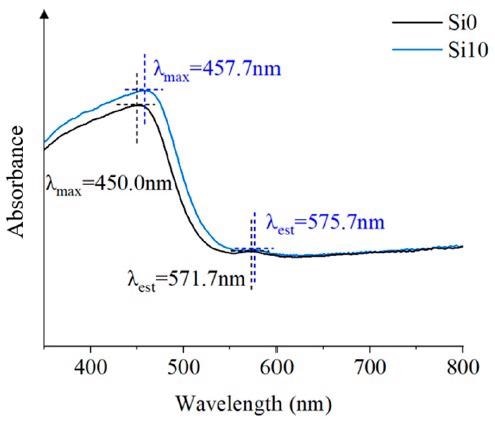

It was discovered that incident light had a significant impact on the material's discharge behavior. The high adsorption frequency in the near-UV and visual regions shifted to the high-frequency orientation with the inclusion of Nanocomposites, resulting in a redshift. This demonstrated that after the addition of SiO2, SiO2 was more able to absorb visible light, easily develop interparticle conduction electrons cross-linking, boost the charge carrier complex formation of polyimide, and improve the material's electrostatic interactions to enhance the composite film's compressibility and emission sensitivity.

Brighter nanoparticles were spread on the material's morphology after intermingling 10% SiO2 molecules, and the surface of the composite was comparatively standard, which was in line with the outcomes of ultraviolet-visible spectroscopy.

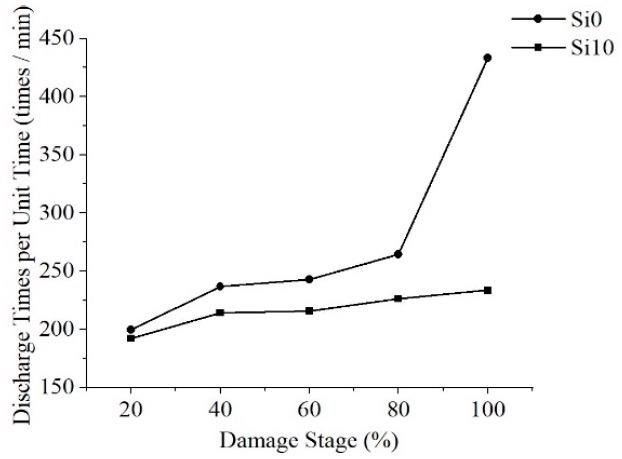

After 40 minutes of release, the Si10 particles were subjected to develop a polygonal and brilliant inorganic phase, which would play a major part in dispersing particles and lowering particle energy. As a result, as compared to the standard polyimide, the interfacial influence and the revealed inorganic phase might reduce the discharged intensity and discharge periods overall following the addition of nanoparticle SiO2.

Ultraviolet-Visible Spectroscopy. Image Credit: Xing, Z. et al., Polymers

Discharge Cycles

Under higher-frequency polarity, the positive half-cycle emission magnitude and emission periods were much bigger than the negative half-cycle emission intensity and discharge rate, and the release was particularly severe during output power polarization change.

The Si0 emission had become more diffused, and a large amplitude creeping emission waveform had emerged. Si10 had a smoother waveform with a dramatically lower magnitude.

The quantifiable statistical results verified that the positive half cycle emission magnitude and discharge rate of the two films are bigger than the negative half cycle release magnitude and discharge durations, as well as the average discharge intensity and discharge rate of the Si10 altogether.

Average discharge times at different stages. Image Credit: Xing, Z. et al., Polymers

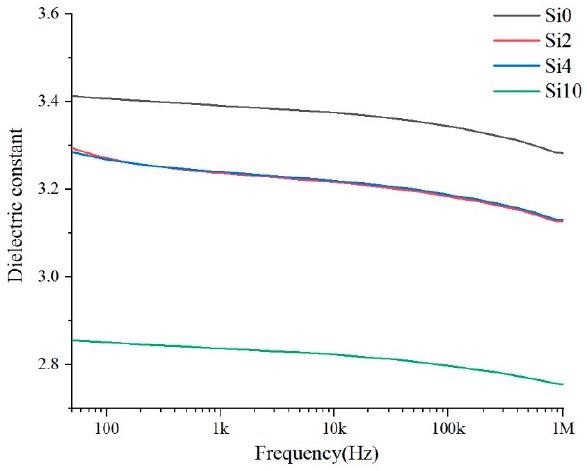

Along with this, there was a gradual decrease in the dielectric value with the doping of the SiO2 particles and this trend was consistent with the addition of increasing concentration of these particles.

Relative dielectric constant. Image Credit: Xing, Z. et al., Polymers

In short, the paper successfully analyzed the discharge of the Polyimide films doped with SiO2. Early on, resistance has a significant impact on its lifespan; the lower the resistivity, the speedier the growth of interfacial discharge. In the intermediate and late stages, the composite's structural features, light absorption qualities, and trap dispersion all play important roles.

References

Xing, Z. et al., 2021. Study on High Frequency Surface Discharge Characteristics of SiO2 Modified Polyimide Film. Polymers, Volume 13(24). 4387. Available at: https://www.mdpi.com/2073-4360/13/24/4387

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.