Oil spills and industrial pollution are significant threats to the environment. Concerns over safety have seen an increased focus on enhancing the filtration of oily wastewater; for instance, at the time of the treatment of sewage.

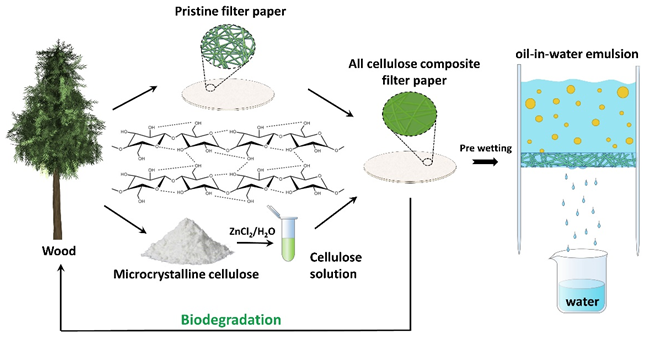

The Closed Loop Process of The Degradable Cellulose Oil-Water Separation Membrane. Image Credit: Institute of Coal Chemistry (CAS).

The Closed Loop Process of The Degradable Cellulose Oil-Water Separation Membrane. Image Credit: Institute of Coal Chemistry (CAS).

The technology of membrane separation provides an effective and encouraging option for treating wastewater, especially with its low energy consumption. But it remains a challenge to find affordable, environmentally-friendly, powerful, and composite membranes that have the potential to obtain a high level of separation.

A research team at the Shanxi Institute of Coal Chemistry (part of the Chinese Academy of Sciences—CAS) has come up with a new and enhanced technique utilizing two various cellulose materials. Their process enables them to achieve membrane materials for oil–water separation that are “all cellulose” (cellulose with two or more various crystal forms).

Significantly, as they describe in their study outcomes, reported in the KeAi journal Green Energy & Environment, their membrane is amiable to the surrounding.

Oil-water separation membrane materials that have been widely used in recent years include vinylidene fluoride (PVDF), polypropylene (PP), polyacrylonitrile (PAN), nylon or their composites. However, these polymers are non-biodegradable and put further pressure on the environment.

Tiansheng Deng, Study Corresponding Author and Professor, Institute of Coal Chemistry, Chinese Academy of Sciences

For this issue to be resolved, Professor Deng and his group selected degradable cellulose that is derived from plants as raw material and further bonded it with commercial cellulose filter paper, which is affordable and porous.

They discovered that numerous nanopores appear in the altered cellulose filter paper, which enhances the barrier against oil droplets of the membrane. When their separation membrane is in touch with the water, a cellulose hydrogel has been developed that, in an efficient manner, isolates oil in water emulsion and oil–water mixture.

Cellulose chains are tightly bonded by a hydrogen bond, with few defects, and the mechanical properties of the material are greatly improved. The high dry and wet mechanical properties of the membrane extend the ways in which it can be applied and help it to remain stable when used in water. We believe this is an important step forward in the treatment of pollution.

Tiansheng Deng, Study Corresponding Author and Professor, Institute of Coal Chemistry, Chinese Academy of Sciences

Journal Reference:

Wang, C., et al. (2022) Efficient oil-water separation by novel biodegradable all cellulose composite filter paper. Green Energy & Environment. doi.org/10.1016/j.gee.2022.03.013