Nanocellulose is a renewable and environmentally friendly material that has been the subject of increasing interest in the scientific community. Nanocellulose materials have traditionally been utilized for their outstanding heat insulation qualities. However, cellulose nanofibrils can demonstrate strong heat conductivity when they are aligned and linked in the form of filaments, broadening the scope of their applications.

Image Credit: TinyPhoto/Shutterstock.com

An Introduction to Cellulose

Cellulose is by far the most common biopolymer on the planet, and it is well known for its renewable, biocompatible, and biodegradable nature.

Cellulose is a type of linear polysaccharide (β (1−4) linked d-glucose units) that is often present as a structural element in plant and algal cell walls or in the biofilm secretions of certain bacterial species.

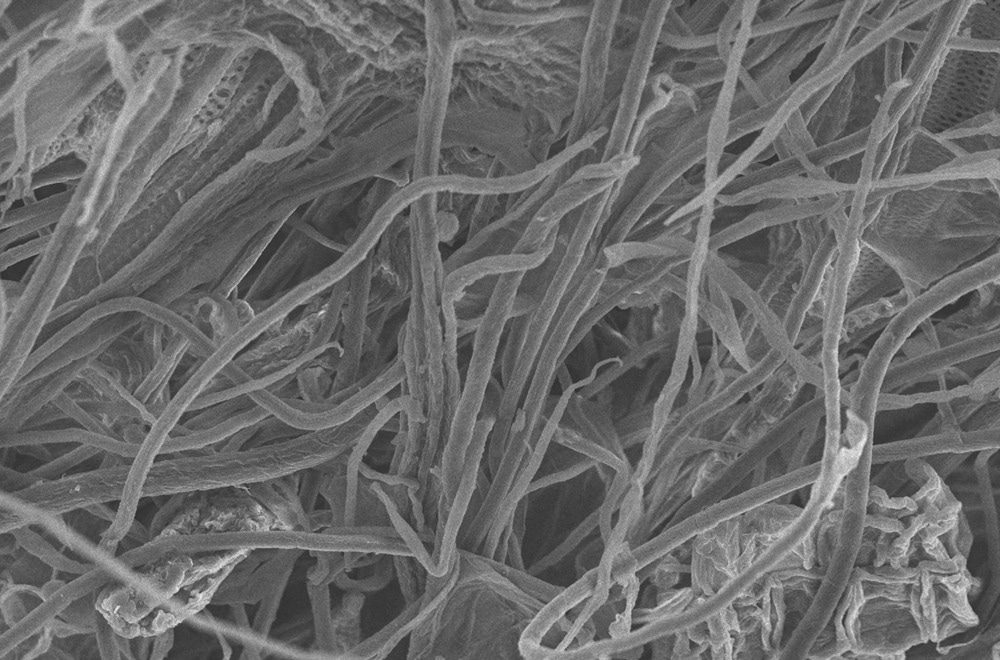

Secondary bonds among polymeric chains (hydrogen bonding and van der Waals forces) encourage parallel stacks and the subsequent production of nanofibrils which have diameters ranging from 5 to 50 nm and include amorphous and crystalline areas.

Cellulose nanofibrils (CNFs) are environmentally friendly nanomaterials that have various benefits, including great mechanical qualities, light weight, and good stiffness, strength, and flexibility.

Cellulose nanofibrils are therefore ideal for the production of bio-based aerogels for thermally insulating the walls and roof cavities of buildings. These aerogels generally exhibit high strength and Young's modulus, moderate light penetrability, and excellent heat insulation qualities.

Approaches for Enhancing Thermal Conductivity of Polymers

Composites have frequently been employed to improve the thermal conductivity of polymers. In this approach, additives like carbon nanotubes or metal nanoparticles are inserted in the polymeric matrices.

The problem with this method is that the thermal interface resistance between the polymeric matrix and the additives restricts the increase in thermal conductance to a single order of magnitude.

In contrast, polymer chain alignment may significantly improve the thermal conductivity and mechanical strength of polymers.

Can Nanocellulose Materials Act as Heat Conductors?

The molecules of cellulose tend to form polymeric chains, which endow nanocellulose materials with properties that could make them good thermal conductors. Recent research on other polymeric chains has indicated that improving their crystallinity and molecular alignment can significantly boost their thermal conductivity.

These findings have sparked efforts to improve the heat conduction of cellulose-based materials by increasing the alignment of nanofibrils.

The Anatomy of Cellulose Fibers

Nanofibrils are the major components of cellulose fibers and have the potential to be the foundations for high-performance biomaterials and fabrics, as well as a benchmark for functional nanomaterials.

The nanofibrils in cellulose fibers are structured in a nanosized lamellar structure with a highly organized spiraling configuration along the axis of the fiber. The fibers exhibit high values of ultimate strength and stiffness, which vary based on the mean fibril orientation.

Individual fibrils or fibril bundles (termed cellulose nanofibrils) may be formed from cellulose fibers.

The inferior characteristics exhibited by CNF filaments and films in existing literature have indicated that the fibrils must be aligned and arranged in a regulated manner to fully unlock the potential of CNF.

The Effect of Hydrodynamic Focusing on Cellulose Nanofibrils

In a study published in the journal Nano Letters, researchers employed a hydrodynamic focusing technique to improve the crystallinity and alignment of individual component cellulose nanofibrils and harness their complete thermal conductivity potential.

In a singular filament of cellulose, a record-high thermal conductivity of 14.5 W/m-K was recorded. These cellulose filaments outperformed thin films of cellulose as well as other pure cellulose nanomaterials in terms of thermal conductivity.

The morphology of the cellulose filaments was studied using Raman spectroscopy to identify the structural elements behind the reported increase in heat conductivity.

They discovered that the cellulose filaments that showed high thermal conductivity also exhibited high crystallinity, which was induced by the alignment and ion-induced gelation of the cellulose nanofibrils during the flow-focusing procedure.

Extensional and shear flows aligned the cellulose nanofibrils and caused ionic bonding during the flow-focusing process.

The results of their study showed that changing the surface activity of cellulose molecules may result in materials with increased crystallinity and, therefore, thermal conductivity.

Factors Affecting the Thermal Conductivity of Cellulose Nanofibrils

When the gelation crystals are irregularly distributed across two or more areas during cellulose crystallization, residual stresses are predicted to occur inside the cellulose nanofibrils. The presence of residual stress inside the filaments affects their crystallinity.

Residual stress produced during the gelation phase is a major cause of the reduction in crystallinity, which ultimately reduces the thermal conductivity of the CNFs.

Cellulose filaments having a smaller diameter and higher crystallinity are generally better thermal conductors because of greater hydrogen bonding between nanofibrils and less disorder within nanofibrils.

Cellulose Nanofibrils with High Thermal Conductivity

The researchers used a hydrodynamic flow-focusing channel mechanism to create a series of cellulose filaments.

Their method enabled simultaneous adjustment of the crystallinity and alignment of cellulose nanofibrils in bulk filaments, which ultimately resulted in good thermal conductivity.

They achieved a thermal conductivity four to five times greater than that of other alternative cellulose-based materials, including nanofibers, filaments, and thin films.

The excellent thermal conductivity, low weight, remarkable mechanical qualities, flexibility, and renewable nature of the cellulose filaments highlight their potential for thermal management applications.

More from AZoM: How are Bacteria Used in Materials Development?

References and Further Reading

Wang, G., Kudo, M. et al. (2022). Enhanced High Thermal Conductivity Cellulose Filaments via Hydrodynamic Focusing. Nano Letters, 8406-8412. Available at: https://doi.org/10.1021/acs.nanolett.2c02057

Håkansson, K. M., Fall, A. B. et al. (2014). Hydrodynamic alignment and assembly of nanofibrils resulting in strong cellulose filaments. Nature Communications, 5. Available at: https://doi.org/10.1038/ncomms5018

Illera, D., Mesa, J., Gomez, H., & Maury, H. (2018). Cellulose Aerogels for Thermal Insulation in Buildings: Trends and Challenges. Coatings, 8. Available at: https://doi.org/10.3390/coatings8100345

Shen, S., Henry, A., Tong, J., Zheng, R., & Chen, G. (2010). Polyethylene nanofibres with very high thermal conductivities. Nature Nanotechnology, 5, 251–255. Available at: https://doi.org/10.1038/nnano.2010.27

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.