Mar 8 2013

Several developments in the use of graphene claimed by nanomaterials companies are most likely for use in high-end or esoteric applications. Allen Clauss, Vice President of R&D at Xolve, a nanomaterials company based in Middleton, Wisconsin, said, “in spite of billions invested in nanomaterials research, no life-changing nano products have made their way to market. Possibly even more telling is the fact that few everyday products contain nanomaterials—these potential wonder materials are still struggling to find their way into common applications in our homes and cars.”

According to Clauss, this shortfall of nanotechnology is predominately due to a single problem. Nanoparticles demonstrate outstanding properties such as exceptional surface area when measured in isolation. However, they have proven to be insoluble and have the tendency to aggregate into clumps and bundles, a hurdle in the realization of their potentially incredible properties in practical applications as these characteristics dramatically negate their super performance potential.

Besides the historical underperformance of nanomaterials, their cost of production and application is also very high, according to John Biondi, the Chief Executive Officer of Xolve. “It has been nanomaterials’ combination of less than optimum performance with high price that has limited applications of these materials, and its an issue that still haunts the application of graphene, the primary nanomaterial that we use at Xolve”, said Biondi.

However, both Clauss and Biondi believe that Xolve is capable of addressing these basic issues: performance and price.

Xolve’s Solution

Xolve’s basic discovery tackles the historic aggregation problem that has compromised the performance of nanomaterials and made them costly to make and apply. The foundation discovery was an outcome of the University of Wisconsin and allows for the detection of optimum solvents for a wide variety of nanoparticles. Developing true solutions of nanoparticles addresses the surface area dilemma by preventing aggregation and returning surface area through the dispersion of particles in solvent. This base technology can economically exfoliate common materials such as graphite to produce nanomaterial form such as graphene.

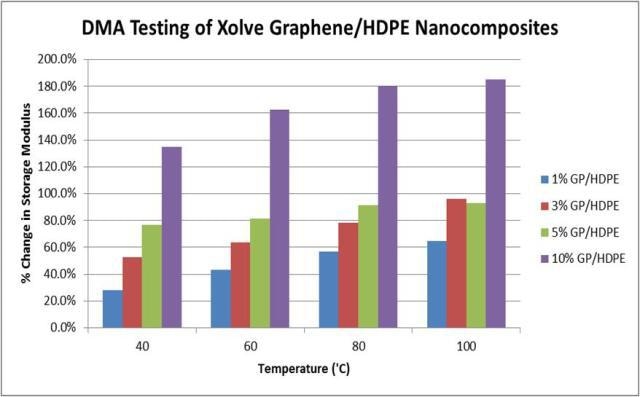

Figure 1.

“In attempts to make forms of nanocarbon useful, previous methods relied on adding materials to the nanocarbon byeither covalent functionalization or through the use of surfactants and/ordispersants,” said Clauss. “Functionalization is the attachment of molecules to the nanoparticle to make it capable of being used with other materials. This process is expensive and limits the potentially superior properties and can partially destroy the nanoparticle to which the process is applied,” he added.

The prevention of nanoparticle aggregation through the use of surfactants and/or dispersants causes contamination of the surface of the nanoparticles and of the host material, pointed out Clauss. “Nanomaterials treated in either of these fashions aren’t able to provide performance equal to their full potential and are very expensive to place into applications”, said Clauss.

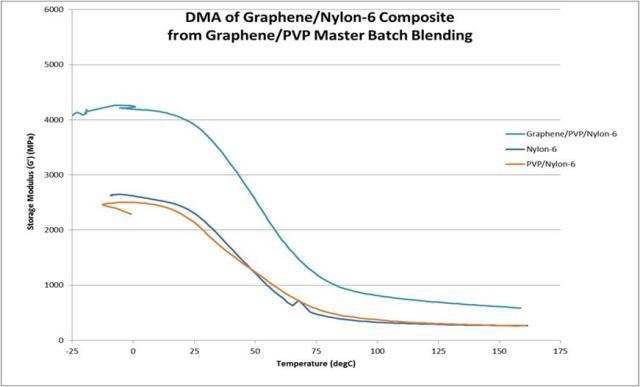

Figure 2.

Xolve has further developed its initial discovery through a suite of technologies that will target the price/performance ratio of nanomaterials in the field of applications of energy storage materials and polymer composites, according to Biondi.

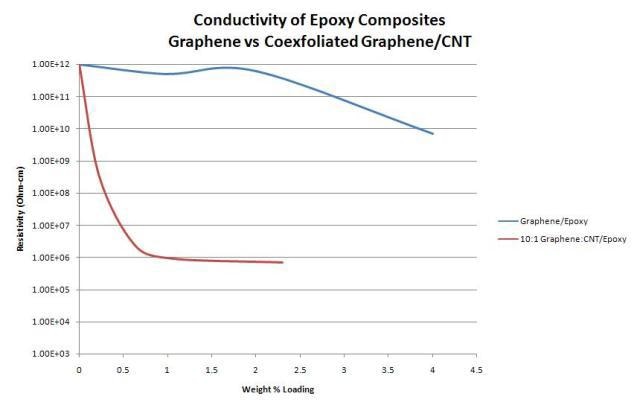

Figure 3.

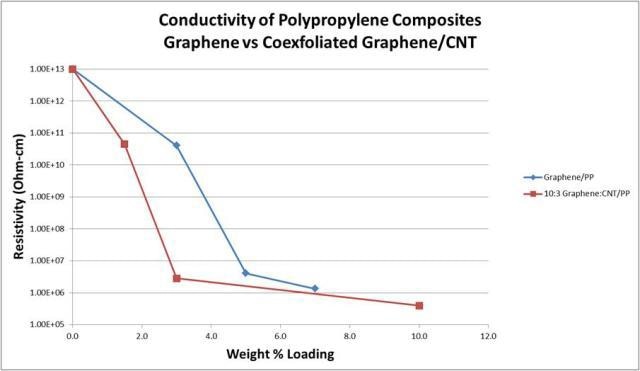

Once a true solution of nanoparticles, such as graphene, in optimized solvents is created, Xolve’s technology can improve the material’s performance properties such as conductivity, modulus and barrier properties. This optimization technology, for instance, improves electrical conductivity level in target polymers by co-exfoliating nanomaterials such as carbon nanotubes and graphene into the polymer matrix. This results in a nanomaterial interactive system with conductivity better than either graphene or nanotubes. Moreover, the resultant interactive system is comparatively less expensive than one based on nanotubes alone. After the exfoliation and optimization of the nanomaterial, it is necessary to place it into a target material without compromising the level of exfoliation and optimization. Xolve has created a chemical toolset that enables it to achieve that across a variety of key industrial polymers.

Figure 4.

Conclusion

Xolve is capable of drastically change thermal conductivity, electrical conductivity, strength, and barrier properties in a myriad of polymer composites at costs comparable to those of standard materials, according to Biondi. Moreover, the company can modify different characteristics concurrently, he added. “It is through our expanding range of technical capabilities that we hope to fundamentally shift the price performance of graphene and other nanomaterials in common applications,” he concluded.

About Xolve

Xolve technology addresses both of the fundamental problems of nanomaterials: performance and price. The Company’s platform discovery has the capability of actually dissolving nanoparticles in stable solutions. This capability correctly prepares nanomaterials to better achieve actual performance close to projected performance limits. Xolve’s base technology also allows for the manufacture of nanomaterials, such as graphene, in a very pristine form and at the lowest cost in the industry.

Of equal importance to the primary manufacture and preparation of the nanomaterial, Xolve’s technology also makes these materials cheaper and simpler to apply. Xolve’s first commercial expression of these dual technical capabilities is in the application of its high quality, low-cost graphene to polymer composites and energy storage materials. Xolve has developed a series of tools that can take exfoliated nanomaterials and place them into or on a significant array of polymer composites, inexpensively modifying a range of attributes of those materials to improve their performance in commercial applications.

This information has been sourced, reviewed and adapted from materials provided by Xolve.

For more information on this source, please visit Xolve.