The VSP-G1 nanoparticle generator offers customers the chance to perform advanced research within the domain of nanomaterials without the restrictions of common generation methods and materials.

Material Versatility

Mix and match metals - The VSP-G1 uses two electrodes as base material to form sub 20 nm particles. Below 20 nm, quantum effects of nanoparticles can be applied for all kinds of applications.

All solid (semi)conductive materials that can be processed into electrodes can be used in this device. This allows for the creation of particles of bi-metals, nano-alloys, or materials that are immiscible in bulk state.

Easier, Faster and Reproducible Production of Nanoparticles

The present approaches to develop nanoparticles are intricate, which makes them time consuming and restricted to only a few materials. With the VSP-G, Scientists can bring back months of work to just a matter of hours or days:

- Fast: the VSP-G1 offers unproblematic interchangeability of electrode material

- Reproducible: After the ideal settings are defined, users will have nothing to stop them from reproducing it with the VSP-G1

- Easy: Controlled by just three buttons. The first one serves as on/off switch and emergency stop, while the other two are used to modify the particle size and production rate. The VSP-G1 is operated at standard pressure and room temperature.

Very Small Particles

Output distribution of particles between 0-20 nm – Producing big particles at high concentrations is easy, but creating minuscule particles at high concentrations is one of the most difficult tasks in material science and aerosol research. The VSP-G1 delivers high output of minute particles, beginning from atom clusters of a few atoms.

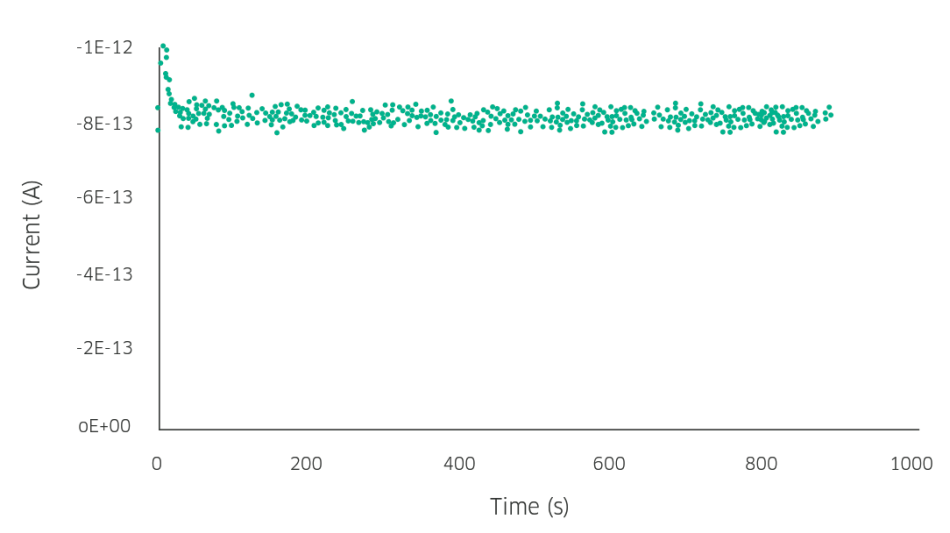

Ultra-Stable and Reliable Aerosol Output

Stability of 98% in long term experiments - Modern experiments in material science and aerosol research demand an extremely stable and very reproducible output of sub 20 nm particles. The VSP-G1 has a highly reliable production output, with an average stability up to 98%. This will help to speed up one’s research and increase reproducible results over long term experiments.

No Chemicals Needed

The spark ablation process applied in the VSP-G1 is a truly physical procedure that only requires an electrode material, carrier gas and electricity to produce clean nanoparticles. No additional chemicals are required for the manufacture or to stabilize the particles in the aerosol.

The mass-produced nanoparticles can be straightaway added into the following process step or applied in a product by, for instance, impaction, electrostatic precipitation or filtering.

This way the exclusive physical properties of the nanoparticles are directly available in the product. The carrier gas can simply be recycled by passing it through a filter and used again, minimizing the environmental impact of the process.

Download the Brochure for More Information

Download the Brochure for More Information

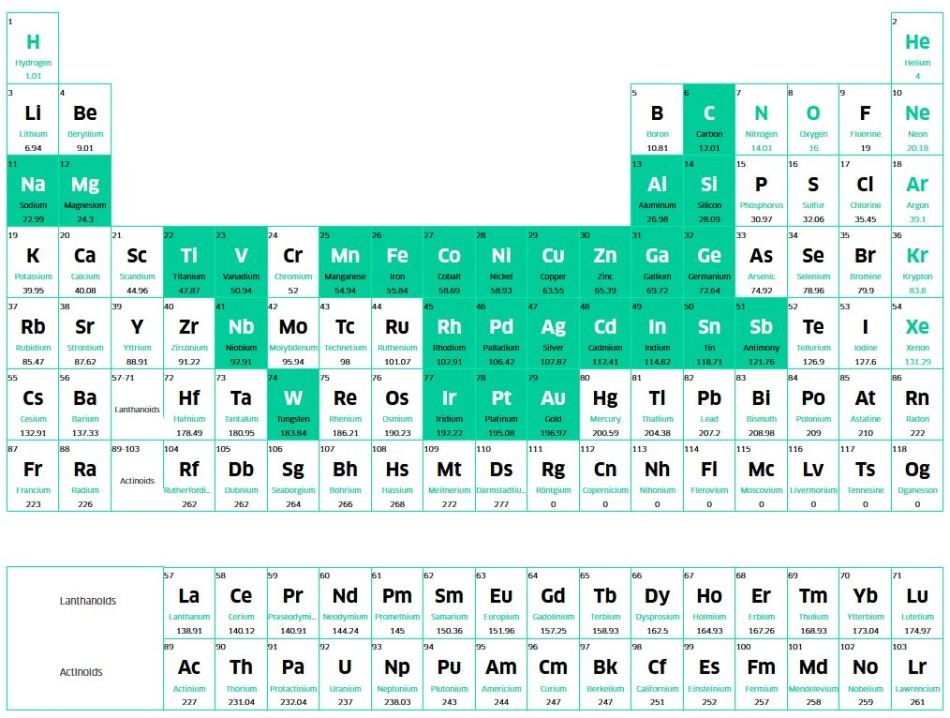

Use of Any (Semi-)Conductive Material

Spark ablation is an adaptable technology that works with a wide range of materials, including metals (for example tungsten, copper, silver, gold, platinum or nickel), semiconductors (for example silicon) and carbon.

In the table provided below, elements highlighted in green are those that have been found to be well-matched with spark ablation. Other elements for which information is available are presented in black while elements that may be employed in the spark ablation process (for example as carrier gas or modifier) are displayed in green.