This advanced zirconia-based ceramic composite material—CeramaZirc Ultra Tough—is based on partly stabilized zirconia and a vastly improved crystal structure. It is the newest and toughest monolithic ceramic composite on the known market and has just been launched by Precision Ceramics USA.

Zirconia (ZrO2) ceramic materials, also known as “ceramic steel”, provides a combination of high hardness, corrosion, and wear resistance, while simultaneously maintaining one of the highest figures for fracture toughness available.

CeramaZirc ultra-tough is DOUBLE the toughness of yttria-stabilized zirconia, and harder as well-meaning that it outperforms the standard material across the board of mechanical properties.

Key Properties of CeramaZirc Ultra Tough

- Hot isostatically pressed (HIP’ed) for excellent reliability and strength

- Use temperatures up to 1500 °C in non-structural applications

- Extraordinarily high impact resistance and fracture toughness and maintains above-average values for hardness and bending strength

- No compromise between fracture toughness, hardness, and bending strength

- Improved resistance to hydrothermal aging via Ceria partial stabilization

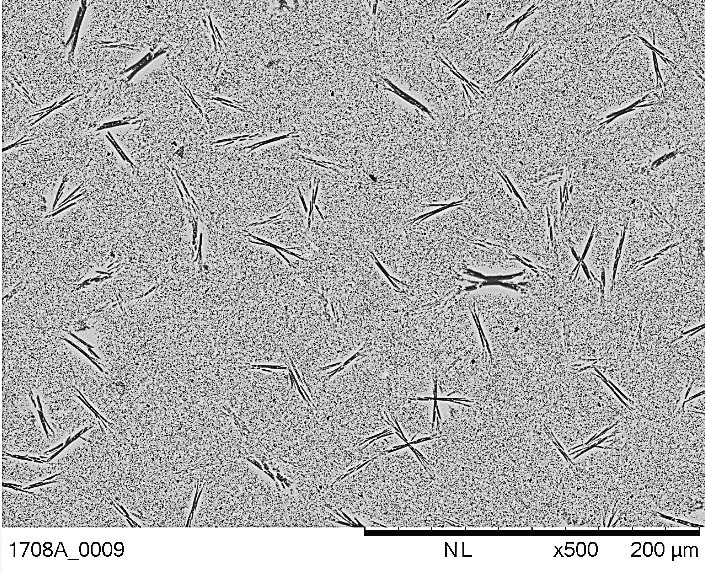

- Toughening by crack deflection offered by the specialized microstructure

Typical Uses of CeramaZirc Ultra Tough

- Ultra-high pressure pumping elements

- High-pressure equipment—such as ball valves, balls, and seats—is especially appropriate for applications, where impacts and/or vibrations and mechanical shock are present

- Guides and rollers for metal forming

- Deep well down-hole valves and seats

- Flow control devices for ultra-high pressure equipment; seats and stems for high-pressure homogenizers

CeramaZirc Ultra Tough

- Flexural strength [MPa] = 1000

- Density [g/cm3] = 5.7

- Young’s Modulus [GPa] =235

- Compressive strength [MPa] = in excess of 2000

- Hardness HV 0.5 [GPa] = 13

- Poisson ratio =0.29

- Maximum use temperature [oC] = 1000

- Fracture toughness KIc [MPa/m2] = 17

*KIc toughness as determined by the indentation method

N.B. Values presented are mean values for the samples tested and are given as an indication only for the purpose of comparing between different materials. The properties of the actual material might vary slightly and could be affected by the shape and size of the part.