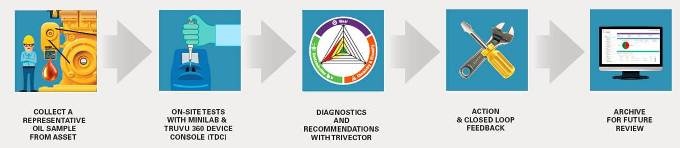

Oil analysis exposes early signs of equipment wear and detects the root causes of corrosion. On-site oil analysis removes the wait linked with conveying samples off-site and allows speedy decision making.

The MiniLab 23 with two standard tests delivers on-site oil analysis, offering instant actionable results, saving time, and decreasing costs. System highlights include:

- Single product, enabling lab-quality analysis to be carried out outside of the lab

- Streamlined workflow for the non-expert user, a chemist is not necessary

- Simplified working, data reporting, and report interpretation via the TruVu 360 Diagnostic Sets with proposed actions

Highlights

The MiniLab 23 offers oil condition information such as chemistry, viscosity, and water in oil. This capability is the basis of an oil analysis program.

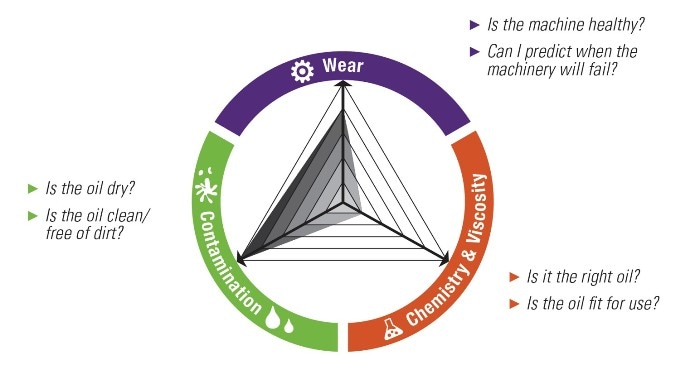

Trivector™ – Oil and Machine Health Simplified

The TriVector™ is a simple representation of the reliability of the lubrication system and the machine’s health itself. The Trivector shows the degree of health in each vector. So as to comprehend the Trivector condition, a user has to measure the central chemical and physical parameters of the oil.

The following questions can be answered:

The MiniLab 23 integrates two basic tests that can be completed within 7 minutes.

| |

Parameter |

Viscosity

ASTM Method D8092 |

Chemical

ASTM Method D7889 |

| Contamination |

Particle count and ISO codes |

|

|

| |

Non-metallic particle count, distribution and images |

|

|

| |

Boron, Calcium, Sodium, Lithium, Potassium and Silicon |

|

|

| |

Water |

|

V |

| Chemistry |

Viscosity |

V |

|

| |

Total Acid Number (TAN) |

|

V |

| |

Oxidation |

|

V |

| |

Total Base Number (TBN), Oxidation, Nitration, and Sulfation for engine oils |

|

V |

| |

Boron, Magnesium, Calcium, Barium, Zinc, Molybdenum, and Phosphorus |

|

|

| Wear |

Wear particle images, counts and distribution |

|

|

| |

Total Ferrous content, ppm |

|

|

| |

Ferrous particle count and size distribution |

|

|

| |

Copper, Silver, Chromium, Titanium, Aluminum, Magnesium, Nickel, Iron, Manganese, Lead, Tin, Molybdenum, Cadmium, and Vanadium |

|

|

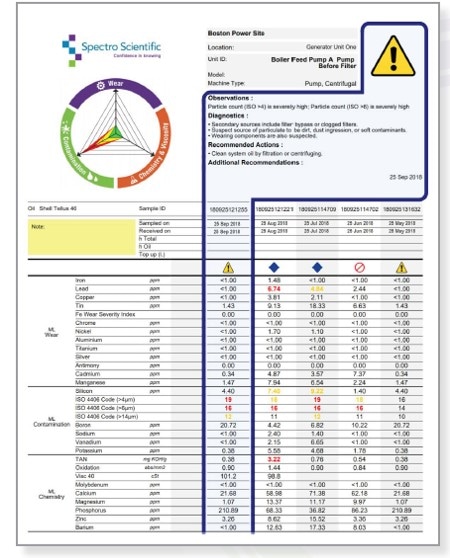

TruVu 360 Enterprise Fluid Intelligence

The Minilab 23 makes use of the TruVu 360 Enterprise Fluid Intelligence software which comprises of reference oil database and an Asset Management database. The databases can be expanded by the end user.

It offers basic sample trend reports and Diagnostic Sets comprising of diagnostics, alarm limit templates, and recommended actions. It can help automatic email distribution of reports.

Color-coded Trivector reports offer a distinct snapshot of machinery health by finding parameters that are beyond standard limits.

Target Industries

The MiniLab 23 is suitable for a broad range of industries such as:

- Metals processing

- Power generation

- Industrial manufacturing

- Pulp and paper

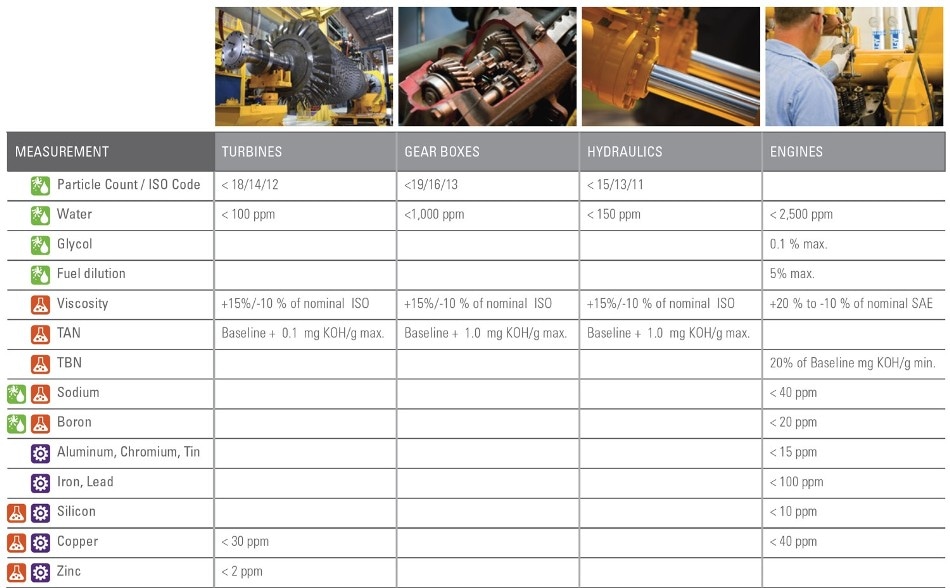

Typical Limits for Machinery

The most typical oil analysis tests and standard alarm limits for a number of component types are illustrated below. Component manufacturers set the alarm limits for their equipment for definite parameters.