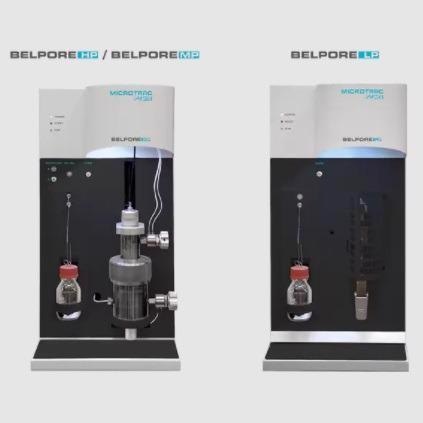

The BELPORE mercury porosimeter series for low-pressure (LP), medium-pressure (MP) and high-pressure (HP) reliably and reproducibly measures pore diameters ranging from 1 mm to 3.6 nm.

The understanding of porosity, pore sizes and pore volume is of great importance for the characterization of porous materials. The most common technique for determining the pore size distribution of accessible macro- and mesopores in solids is mercury porosimetry.

The method is based on the pressure-dependent intrusion of mercury as a non-wetting liquid into a porous substance. With the help of the Washburn equation, the corresponding pore size is measured from the applied pressure.

As a provider of advanced solutions in the field of particle characterization and gas adsorption, Microtrac MRB has extended its wide portfolio with a range of devices specifically designed for the field of mercury porosimetry.

The BELPORE porosimeter series includes advanced instruments for analyzing pore size distribution, specific surface area, pore volume, density, porosity and particle distribution of finely divided and porous materials.

Image Credit: Microtrac MRB

Features

- Completely automatic vertical filling under continuous high vacuum

- High resolution allows detection of up to 20,000 measuring points

- Effective re-use of mercury through cleaning set

- Secure and complete functionality without gas connection and liquid nitrogen

- Vertical arrangement of the dilatometers guarantees safe handling

- Compact design, small footprint

- All devices are CE-certified and ISO 9001-accredited

The three mercury porosimeters from Microtrac MRB cover various pore ranges:

- BELPORE LP (1,000 to 3.25 µm): Degassing, Hg filling, low-pressure porosimetry

- BELPORE MP (15 to 0.0065 µm)

- BELPORE HP (15 to 0.0036 µm): MP and HP: High-pressure porosimetry

Image Credit: Microtrac MRB

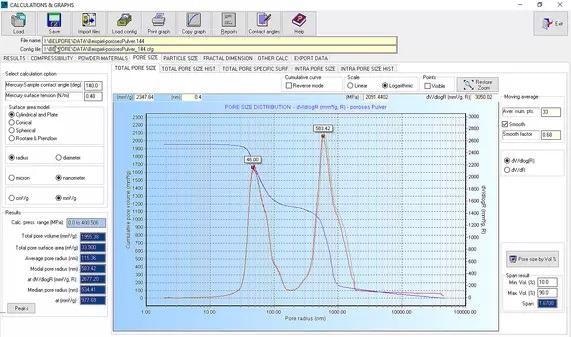

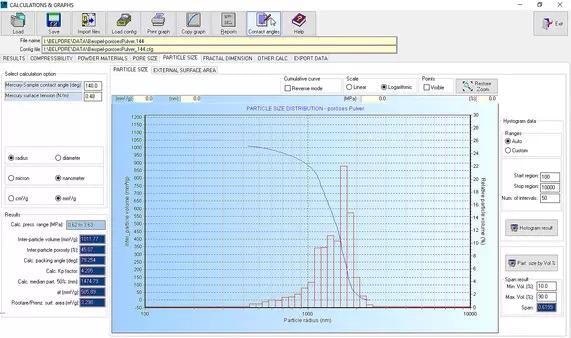

Control and Evaluation Software

Microtrac MRB's PoreInspect software for the BELPORE porosimeter series provides a range of functions. The software tracks and controls up to four measuring instruments connected autonomously through LAN through a PC and permits separate control of all instrument parameters in real-time.

The PoreInspect software’s data evaluation not only considers the exact blank value correction but also permits checks and corrections of possible sample compressibilities, thereby ensuring the most reliable results.

Wide evaluation options include the selection of various pore models and their presentation as histograms and graphics. The calculations are freely selectable based on the application and include, for instance, the representation of fractal dimensions as well as calculations of permeability and tortuosity.

Additional features include overlay, statistical evaluations, the making of a method catalog, and data export. The stored raw data is available at all times.

Evaluating pore size with the PoreInspect Software. Image Credit: Microtrac MRB

Evaluating Particle size with the PoreInspect software. Image Credit: Microtrac MRB