Engineers at EPFL’s Laboratory of Applied Photonic Devices (LAPD), which is part of the School of Engineering, developed a 3D printer that can build items virtually instantly back in 2017. Five years later, the team has refined its printing equipment and procedure to the point that they can now make opaque resin things, which was previously impossible.

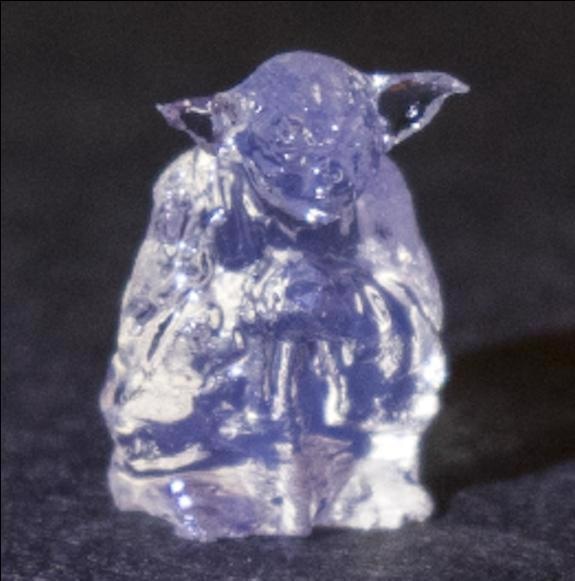

A tiny Yoda. Image Credit: EPFL.

A Tiny Yoda

EPFL’s 3D printer is one of the world’s fastest. Unlike other 3D printers, which employ additive manufacturing to deposit material layer by layer, the EPFL utilizes a volumetric technique.

We pour the resin into a container and spin it. Then we shine light on the container at different angles, causing the resin to solidify wherever the accumulated energy in the resin exceeds a given level. It is a very precise method and can produce objects at the same resolution as existing 3D-printing techniques.

Christophe Moser, Professor, Laboratory of Applied Photonic Devices

The engineers’ volumetric approach can be used to create items of almost any shape, so they decided to put it to the test by making a miniature Yoda. They created the figure in 20 seconds, compared to ten minutes for a traditional additive manufacturing procedure.

Using Light to Solidify Materials

The interaction of light rays with a photosensitive ingredient in the plastic allows the resin to harden.

Our method works only if the light passes through the resin in a straight line without being deviated. Until now we have always used transparent resin, but we wanted to see if we could print objects in the kind of opaque resin that is used in the biomedical industry.

Antoine Boniface, Postdoctoral Researcher, Laboratory of Applied Photonic Devices

The problem with employing opaque resin in volumetric operations is that light does not travel evenly, making it difficult to gather the energy required to harden the resin.

With opaque resin, we lost a lot of resolution in the printed object. So we tried to come up with a solution that would let us fabricate objects in this resin but without losing the advantages of our 3D printer.

Jorge Madrid-Wolff, PhD Student, Laboratory of Applied Photonic Devices

Adjusting Computer Calculations

The engineers’ solution was actually fairly straightforward. They first utilized a video camera to examine the light’s path through the resin, then devised computer equations to adjust the light-ray distortion.

They configured their printer to perform these calculations while printing and adjust the light beams. This ensured that the energy required to harden the resin was applied where it was needed.

The experts were able to print items in opaque resin with nearly the same accuracy as clear resin by tweaking the computer calculations, which is a significant accomplishment.

Biological materials, like artificial arteries, can be 3D-printed using the LAPD approach. The developers hope to be able to print many materials at once in the future and raise the resolution of their printer from a tenth of a millimeter to a micrometer. Advanced Science has published the engineers’ findings.

Journal Reference:

Madrid-Wolff, J, et al. (2022) Controlling Light in Scattering Materials for Volumetric Additive Manufacturing. Advanced Science doi/10.1002/advs.202105144.