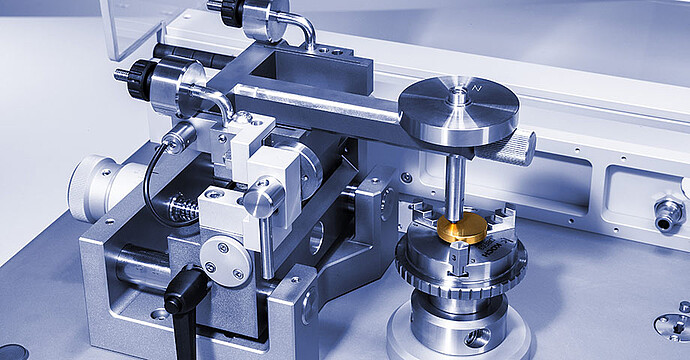

With over 1000 installed bases globally over the last 35 years, Anton Paar's pin-on-disk tribometer is the industry standard for measuring friction, wear, and lubrication. Its extensive set of testing parameters, contact geometries, and add-on options enables users to undertake tribology testing by simulating all in-service situations, such as varied movement modes (linear, reciprocating), contact modes, speed, lubrication, materials, high temperature, humidity, etc.

For conducting research and quality control on novel materials (such as metals, polymers, and ceramics), lubricants and oil additives, and self-lubricating systems, TRB³ has built a solid reputation and demonstrated its dependability in laboratories throughout the globe.

- The benchmark for lubrication, wear, and friction measurement

- Numerous contact geometries, testing settings, and add-on choices

- Delivered with the reference sample kit for instrument performance verification

- Integrated temperature and humidity sensors

Image Credit: Anton Paar GmbH

Key Features

Minimize Thermal Drift with Two Friction Force Sensors

Image Credit: Anton Paar GmbH

The Anton Paar pin-on-disk tribometer TRB³ effectively counteracts thermal drift, which is caused by temperature fluctuations in the surrounding environment and occurs over extended testing periods. The unique design of the two friction force sensors and the symmetrical elastic measuring arm makes this possible.

When the sample is purposefully heated or cooled, and the anticipated friction force is little, thermal drift is significantly more harmful. TRB³ captures hardware-corrected friction data in real-time and concurrently evaluates the difference between the two friction force sensor outputs.

Monitor Environmental Conditions in Real-Time with Integrated Sensors

Image Credit: Anton Paar GmbH

Tribology testing findings are highly dependent on environmental variables, including temperature and humidity, which should be recorded and reported together with other tribological data (particularly in the evaluation of polymers as well as hard coating characterization). The temperature, humidity, friction force, and other testing data are all measured and recorded in real-time by TRB³, thanks to its integrated sensors.

Calibrate TRB³ with Minimum Effort

Image Credit: Anton Paar GmbH

All tribometers must undergo routine calibration for the measured data to be exact and reliable. By allowing customers to carry out crucial calibrations (friction force, motor speed, and rotation radius) themselves, Anton Paar now goes one step further. As a result, users can ensure that their tribometers are always in great condition and save money on maintenance, which may perhaps be more significant.

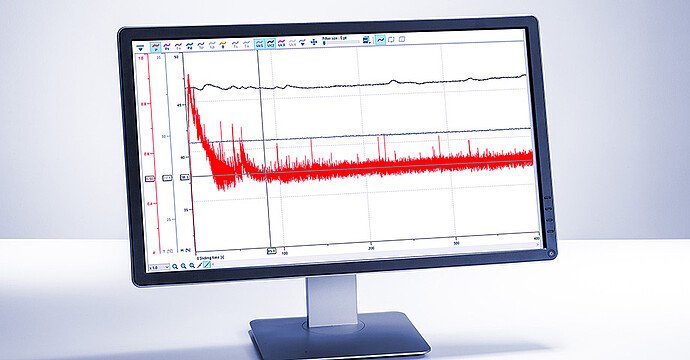

The “Tribometer” and “Modelization” Software Provide Ultimate Control and Cutting-Edge Analysis

Image Credit: Anton Paar GmbH

Anton Paar's tribometer software includes three main parameter setting options (standard, incremental, and user-defined) to accommodate various testing requirements (various speed, load, and movement modes, for example). To simulate the distribution of contact stress and strain, the “Modelization” software is automatically installed, making it simple to select the appropriate measurement settings.

When dealing with linear or angular reciprocating movements, the “cycle explorer view” and “reciprocating analysis mode” simplify data handling. The integrated open-source Python programming environment is prepared for any type of data handling for advanced users.

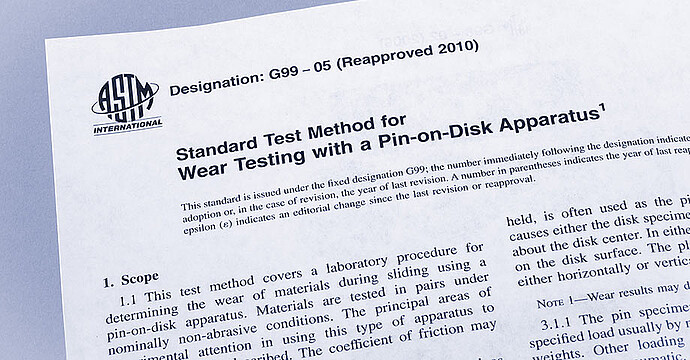

Be Compliant with the Standards – ASTM G99, ASTM G133, and DIN 50324

Image Credit: Anton Paar GmbH

Anton Paar participates in and contributes to several esteemed international standards committees, the most significant of which are ASTM G99 and ASTM G133, as part of the ongoing research and development process in the field of tribological measurement instrumentation. Since TRB³ complies completely with these standards, users can be certain that tribological testing is carried out in accordance with industry best practices.

Technical Specifications

Source: Anton Paar GmbH

| . |

. |

| Normal force range |

up to 60 N |

| Normal force resolution |

- (dead weight) |

| Friction force range |

up to 20 N (5 N option) |

| Friction force resolution |

0.06 mN (0.015 mN option) |

| Rotating movement |

| Speed |

0.2 rpm to 2000 rpm (600 rpm option) |

| Radius |

up to 40 mm |

| Maximum torque |

450 mN.m |

| Linear reciprocating movement1) |

| Stroke length |

up to 60 mm |

| Speed |

up to 370 mm/s |

| Frequency |

0.01 Hz to 10 Hz |

| Rotational reciprocating movement2) |

| Speed |

0.2 rpm to 2000 rpm (600 rpm option) |

| Frequency |

0.01 Hz to 7 Hz |

| Angular amplitude |

±5° to ±150° |

| Angular resolution |

0.1° |

| Options |

| Online wear depth |

-2 mm to 2 mm |

| Heating capability |

up to 450 °C in dry condition

up to 150 °C in liquid condition |

| Electrical contact resistance |

up to 1000 Ohms |

| Vacuum level |

down to 10-7 mbar |

| Relative humidity level |

15 % to 95 % |

1) Linear reciprocating movement specifications depend on the combination of stroke length, frequency, and mass on the stage.

2) Rotational reciprocating movement specifications depend on the combination of angular amplitude, frequency, and mass on the stage.

Vacuum Tribometer: TRB V / THT V

Image Credit: Anton Paar GmbH

- Testing compatible with DIN 50324, ASTM G99 and ASTM G133

- Testing in liquids and controlled humidity

- High-temperature model (max. 1000 °C)

- For varied sample sizes and shapes

The vacuum tribometer measures the sliding life of self-lubricating coatings and the friction and wear behavior of solid-state materials or hard coatings by averaging time, contact pressure, velocity, and temperature under vacuum conditions.

Anton Paar tribometers have shown their dependability globally in over 1,000 facilities for studying:

- High-vacuum environments, down to 10e -7 mbar

- New materials (ceramics, metals, polymers)

- Self-lubricating systems

- Quality assurance

Key Features

Technical Features:

- Testing in liquids and controlled humidity

- Testing compatible with DIN 50324, ASTM G99, and ASTM G133

- Powerful software package for PC

- Friction and wear measurements are well-calibrated

- Stable contact point with no parasitic friction

- Variable sample sizes and shapes

- Automatic shut-off (max. track length / max. friction coefficient)

Additional Capabilities:

- High-speed motor (1500 rpm)

- Electrical contact resistance

- High-temperature model (1000 °C max temperature)

- Range of ball/pin holders available

- Contact depth measurement

Technical Specifications

Source: Anton Paar GmbH

| . |

. |

| Rotation speed |

Up to 600 rpm

(optional 1500 rpm) |

| Maximum torque |

450 mNm |

| Friction force (LVDT sensor) |

up to 10 N

(optional 20 N) |

| Maximum disk dimensions |

Ø max. 55 mm;

Ø min 11 mm;

Thickness up to 10 mm |

| Maximum normal load |

10 N

(optional 60 N) |