Horiba has developed the EMGA-930 O/N/H analyzer, a “New flagship model” for O/N/H analyzers and user-friendly products.

This is a concurrent nitrogen, oxygen, and hydrogen elemental analyzer exhibiting high precision and repeatability, befitting to cutting-edge technology’s R&D and quality control in the market of new materials, steel, catalyst, etc. This is known to be a new generation model that has been improved to suit user requests.

The oxygen is quantified as carbon dioxide and carbon monoxide by two non-dispersive infrared detectors, the hydrogen with a non-dispersive Infra Red detector as H2O, and the nitrogen by a thermal conductivity detector.

Features

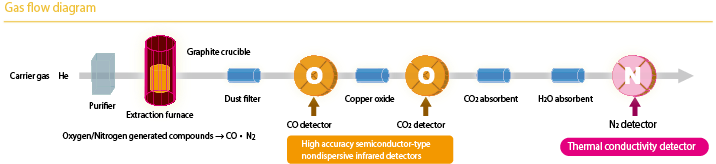

Principle and gas flow diagram

The sample has been placed in a graphite crucible and the crucible is retained between the lower and the upper electrode of the impulse furnace. A high current power passes via the crucible for a high temperature to be created.

The oxide present in the sample reacts with the graphite crucible and has been extracted as carbon monoxide (CO), and carried collectively with the carrier gas. The extracted gas is directly examined following the dust filter.

As per the oxygen concentration, it has been identified by CO or CO2 after passing through an oxidizer (copper oxide) with a non-dispersive Infra-Red analyzer (NDIR).

The hydrogen has been identified with a non-dispersive Infra Red analyzer as H2O after H2 passes via the oxidizer (copper oxide).

Gas flow diagram. Image Credit: Horiba Scientific

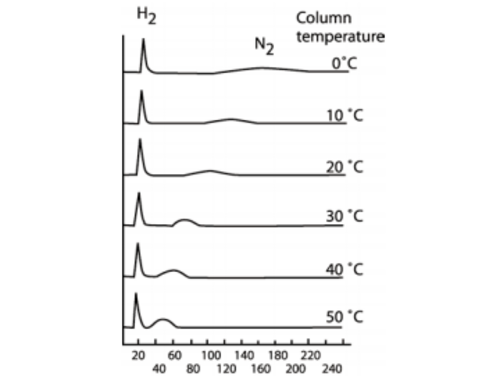

The nitrogen present in the sample has been extracted as nitrogen gas (N2) and its concentration is identified by a thermal conductivity detector (TCD).

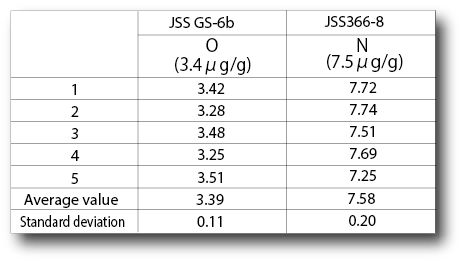

Super High Performance

Wide range and high accuracy measurement

0-5%, Nitrogen: 0-3%, Hydrogen: 0-0.25%

σn-1≦0.02 ppm or CV≦0.5% for Reference gas

σn-1≦0.3 ppm or CV≦1.0% for STD sample

σn-1≦0.04 ppm or RSD≦2.0% for Reference gas

Extensive range measurements have been offered by double detectors of oxygen (CO and CO2), long-type cell, and improved design of TCD.

Optimization of the signal processing decreases by half the electrical noise in comparison to the conventional model.

Source: Horiba Scientific

Standard

EMGA addresses the needs of the standard method for analysis of ceramics, steel titanium, etc.

EX)

- *ISO10720, ISO17053

- *JIS G1228

- *ASTM E1019, ASTM E1569, ASTM E1409

User-Friendly Software

Measurement window

Simple software enables easy handling.

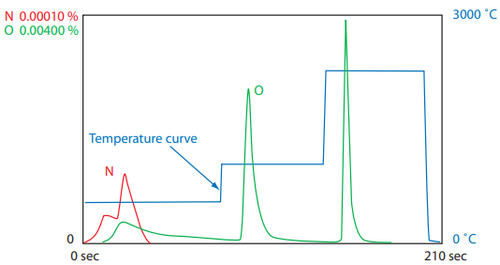

Extracted gas signals have been exhibited in real-time numerically and as curves collectively with temperature level. Graphs are saved automatically.

In the measurement window, it is possible to register sample weight automatically. The outcomes are saved in a data table for seamless management.

Image Credit: Horiba Scientific

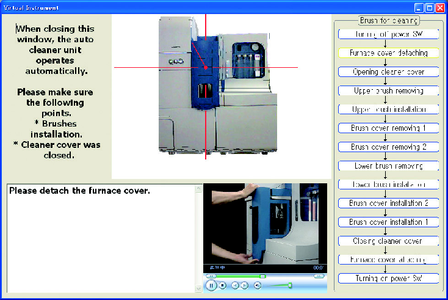

HORIBA Originality-Maintenance Navigator

To retain high accuracy, the maintenance counter notifies users at the time of consumables replacement.

As the navigator explains the easy-to-comprehend procedure for replacing parts, an operator could perform maintenance works with completely no technical knowledge and experience.

Image Credit: Horiba Scientific

Specifications

EMGA-930: Oxygen/Nitrogen/Hydrogen Analyzer

Principle

- Oxygen: non dispersive infrared detector

- Hydrogen: non dispersive infrared detector (as H2O)

- Nitrogen: thermal conductivity detector(TCD)

Measurement range*:

- Oxygen: 0-5%, nitrogen: 0-3%, hydrogen: 0-0.25%

- Up to 100% wt is possible by decreasing the sample weight.

Sample weight: 1.0 ± 0.1 g

Sensitivity (minimum reading): Oxygen/nitrogen/hydrogen: 0.001 ppm.

Accuracy** (repeatability)

Oxygen/nitrogen

σn-1≦0.02 ppm or RSD≦0.5% whichever is larger (Reference gas)

σn-1≦0.3 ppm or RSD≦1.0% whichever is bigger (Standard sample)

Hydrogen

σn-1≦0.04 ppm or RSD≦2% whichever is larger (Reference gas)

**Based on the sample weight 1.0 ± 0.1 g and with automation functions described below

Display

1) Measurement result: printout or LCD

2) Flow sheet: LCD

3) Alarm message: LCD or printout

Power of furnace

- Inert gas fusion in impulse furnace

- Enable to set the generating power from 0 to 8.0 kw

Sample introduction: Dual sample/flux introduction mechanism

Automation functions: Auto cleaner and crucible loader

Integration conditions:

- Integration up to reach comparator level

- Preset time integration is given

- Preset time integration or integration up to reach comparator level, whichever is shorter

Sample ID: Enter a maximum of 20 one-byte characters

Calibration

- One point or multi point calibration (standard samples or reference gas)

- Calibration curve correction function

- Calibration can be done by making earlier analysis data

Functions

- Analysis interruption

- Display of real time extraction curve

- Self-diagnosis and alarm display

- Output (RC-232C or TCP/IP)

- Analysis of extraction curve (Superposition, difference etc analysis)

Dimensions: 750 mm (H) ×785 mm (D) × 653 mm (W)

The sample introduction is placed at 650 mm from the table.

Weight: 230 kg

- On carrying, it is split into two units (Under 140 kg/unit)

- Computer: PC model operating OS Windows® XP (SP2) and beyond

Power

- Main unit: AC 200/220/230/240 V ± 10%

- Frequency: 50/60 ± 1 Hz

- Auto cleaner: AC 100 V (Step-down transformer)

Electric power consumption

- Main unit: 12 kVA (MAX)

- Auto cleaner: 1.5 kVA (MAX)

Ground resistance: Less than 10 Ω

Installation condition

- Operation temperature: Ranges from 5 to 40 °C

- Performance temperature: Ranges from 5 to 35 °C

- Humidity: Maximal relative humidity 80% RH between 5 and 31 ℃, linearly reduce down to 50% RH between 31 and 40 ℃

- Vibration: Duplex amplitude goes up to 20 µ and less than 0.098 m/S2 accelerations at frequency band

Required Gas

- He carrier gas: Purity goes above 99.995%, Pressure 0.35 MPa

- Dry air or N2 as operating gas: Pressure 0.45 MPa

- Stainless steel pipe (O.D.3 mm) and ideal connecter fitting within 3 m of unit

- Nylon pipe (O.D.6 mm) and suitable connecter fitting within 5 m of unit

Cooling mechanism: Radiator unit (Separation type)

Electronic balance (option)

Allow connection with electronic balance with 1 to 0.01 mg minimum display

Optional automatic voltage regulator (AVR)

- Capacity:15 kVA

- Weight: 130 kg

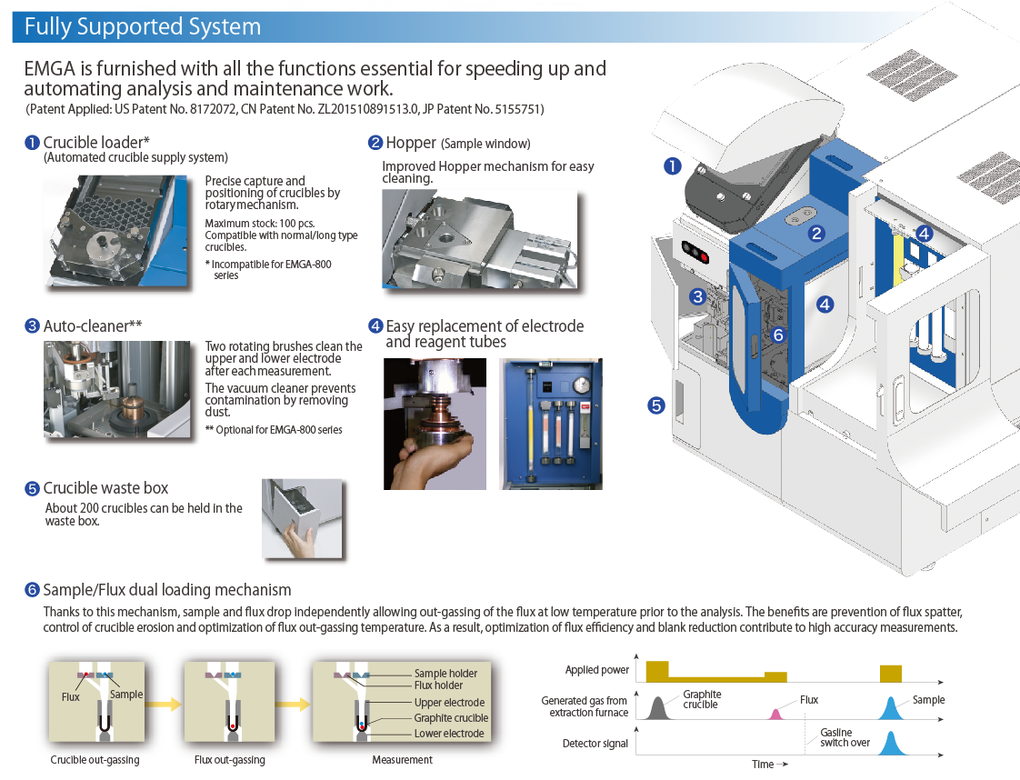

Fully Supported Accessories Give Simple Operation

Image Credit: Horiba Scientific

Applications

Some applications include:

- Law nitrogen determination in steel

- Battery evaluation in electrical equipment

- Analytical chemistry in chemicals

- Quality assurance for the analysis of steel by gas component analysis

- Sample preparation and sampling methods for the gas analysis of steel

Image Credit: Horiba Scientific

Hydrogen analysis in steel and metals: solid extraction or fusion

In various sample types, such as non-ferrous metals, ferrous metals, semiconductors, or electronic materials, EMGA has been developed for precise measurements of hydrogen content. The hydrogen content has been withdrawn by fusion of the sample in inert gas and examined by a high-sensitivity thermal conductivity detector.

It is possible to avoid fusion and withdraw hydrogen content in the sample by heating below the melting point.

The hydrogen analysis of solid samples

On a yearly basis, the marketplace witnesses high demands for the analysis of hydrogen contained in several sample materials.

Image Credit: Horiba Scientific

Oxygen and nitrogen determination in aluminium nitride

EMGA-920 can quantify high levels of nitrogen while retaining the required accuracy for oxygen determination in AIN.

Image Credit: Horiba Scientific

Oxygen and nitrogen determination in boron nitride

EMGA-920 quantifies high levels of nitrogen while concurrently identifying the existence of low levels of oxygen with good accuracy.

Image Credit: Horiba Scientific