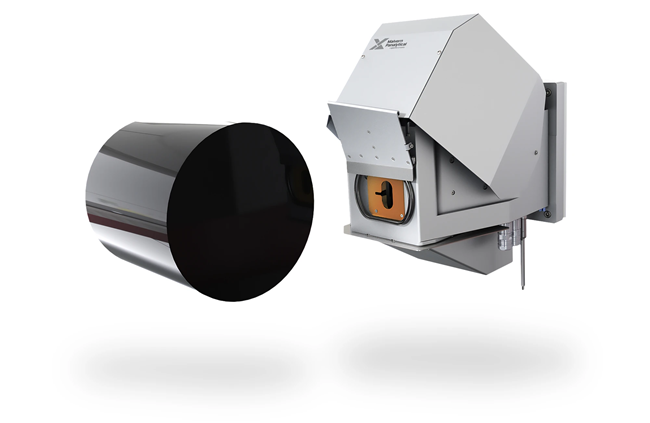

XRD-OEM

Fully Automated In-Line Orientation and Handling of Ingots, Boules, and Pucks

The dedicated solution for automated in-line handling, machining, and measurement of ingots, boules, and panels. XRD-OEM is designed for peak performance even in the most challenging environments.

XRD-OEM is a resilient solution that enhances productivity, ensures quality control, and optimizes your production processes.

Image Credit: Malvern Panalytical Ltd

Overview

XRD-OEM stands as a transformative force for the production processes. Engineered to endure the demanding conditions of grinding and sawing, this X-Ray diffraction instrument seamlessly integrates with any processing system, thanks to its industry-standard interfacing.

XRD-OEM delivers independent orientation measurements for ingots, boules, or panels, facilitating measurements on both flat surfaces and circumferences. Optical notch detection ensures precise pre-alignment before the sawing or grinding processes.

Features and Benefits

Compact and Connected

Tailored for seamless integration with any automation or processing system, XRD-OEM facilitates a streamlined, efficient, and uninterrupted operation.

Its compact design and standard industrial interfaces guarantee easy incorporation into any manufacturing setup, ensuring compatibility with the existing instruments and systems.

Image Credit: Malvern Panalytical Ltd

Tough Enough for the Process

Crafted for durability, XRD-OEM is deployable in any environment you require, including grinding and sawing processes. It remains reliable and precise, maintaining performance even under demanding production conditions.

Image Credit: Malvern Panalytical Ltd

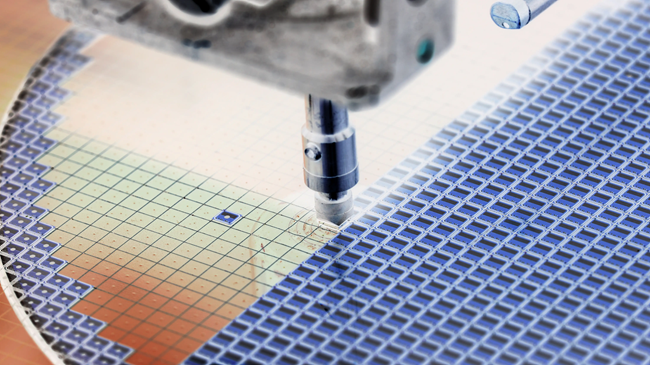

Fast and Precise

XRD-OEM provides automated precision where it is most crucial. The accurate determination of crystal orientation directly inside, for example, a cutting or grinding machine, upholds stringent quality control standards, optimizing the processes for increased efficiency and overall quality.

XRD-OEM excels in determining crystal orientation on both flat surfaces and circumferences, adding an extra layer of versatility.

Image Credit: Malvern Panalytical Ltd

Optical Notch Detection

Optical notch detection precisely identifies and characterizes flat and notch features on the samples, playing a crucial role in the pre-alignment of large ingots before the sawing or grinding processes.

Image Credit: Malvern Panalytical Ltd

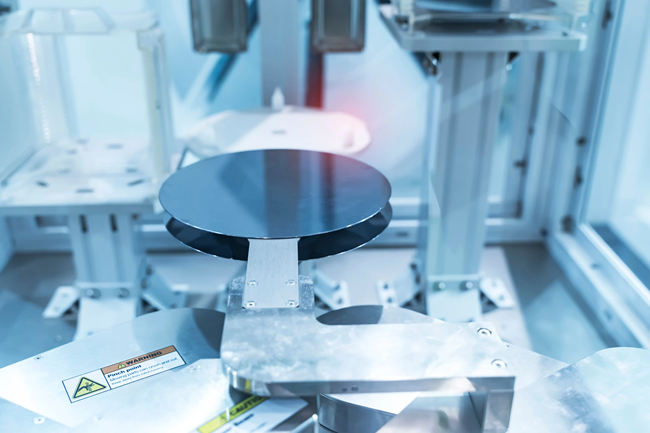

Wide Range of Sample Sizes

XRD-OEM can determine crystal orientation on both flat surfaces and circumferences, adding an extra layer of versatility.

Image Credit: Malvern Panalytical Ltd

Key Applications

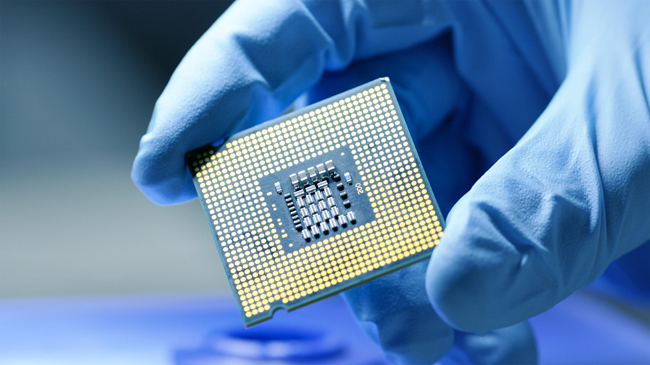

Production and Processing

Tailored for users bustling production environment, XRD-OEM is crafted as an in-line instrument, ready to seamlessly integrate into the automated high-throughput setup. It serves as an efficient solution for measuring and handling ingots, boules, and panels.

With the capability to measure a variety of compound semiconductor materials, including Si, SiC, GaAs, and more, its air-cooling and compact size make it a potent and cost-effective addition to their process.

Ingot Pre-Alignment Before Sawing or Grinding

Through its precise pre-alignment capabilities, XRD-OEM facilitates accurate positioning and orientation control before advancing to subsequent processing steps.

Quality Control

In the realm of production, swift orientation measurements are imperative, and XRD-OEM excels in delivering high-quality data with speed. By seamlessly integrating into both new and existing automated processes, XRD-OEM positions users to embrace the automated future of manufacturing today.

Specifications

Source: Malvern Panalytical Ltd

| . |

|

| Orientation precision |

<0.003° |

| Notch position |

0.005 ° |

| Notch depth |

0.005 mm |

| Notch profile angle, typical |

< 0.5 ° |

| Diameter |

0.02 mm |

| Flat position |

< 0.03 ° |

| Flat length |

< 0.3 mm |