SDCOM

Ultra-Fast, Flexible Crystal Orientation in a Compact Package

Capable of measuring crystals with a starting size of 1 mm, the SDCOM employs the azimuthal scan method to accurately ascertain the complete lattice orientation of single crystals in a single measuring rotation, taking just a few seconds.

Versatile and accessible, the SDCOM is suitable for both research and production quality control, seamlessly integrating into various wafer and ingot process steps without the need for water cooling.

Image Credit: Malvern Panalytical Ltd

Overview

Experience accessible and rapid crystal orientation measurement with the SDCOM, the user-friendly compact XRD solution. Utilizing the azimuthal scan method enables ultra-fast measurements, providing results in under 10 seconds. The SDCOM ensures the highest level of precision, reaching up to 0.01 °.

With a diverse range of sample holders and transfer fixtures, including a marking option for lateral crystal direction, this easy-to-use compact device is the ideal solution for numerous applications in wafer processing and research.

Features and Benefits

Ultra-Fast and Precise: Azimuthal Scan Method

The azimuthal scan method requires just one full sample rotation to collect all essential data for a comprehensive orientation determination, offering high precision within a brief measuring time, typically in the range of a few seconds.

During this process, the sample undergoes a 360-degree rotation while the X-Ray source and detector are strategically positioned to achieve a specific number of reflections per turn. These reflections enable the precise measurement of the crystal lattice orientation in relation to the rotation axis, accomplished swiftly and with high accuracy.

Image Credit: Malvern Panalytical Ltd

Compact and Versatile

SDCOM boasts a lightweight and compact design, facilitating easy placement and seamless integration into the processes, whether in a research or industrial setting. The XRD Studio software, known for its powerful and intuitive features, ensures convenience and user-friendly operation across a diverse user base.

The SDCOM emphasizes flexibility, which is evident in its ability to measure a broad range of materials. Capable of measuring crystals starting from 1 mm in size, it offers versatility in applications. Examples of measurable materials include:

- Cubic, arbitrary unknown orientation: Si, Ge, GaAs, GaP, InP

- Tetragonal: MgF2, TiO2, SrLaAlO4

- Orthorhombic: Mg2SiO4, NdGaO3

- Cubic, special orientation: Ag, Au, Ni, Pt, GaSb, InAs, InSb, AlSb, ZnTe, CdTe, SiC3C, PbS, PbTe, SnTe, MgO, LiF, MgAl2O4, LaTiO3, SrTiO3,

- Hexagonal and trigonal: SiC 2H, 4H, 6H, 15R, GaN, ZnO, LiNbO3, SiO2 (quartz), Al2O3 (sapphire), GaPO4, La3Ga5SiO14

Additionally, a diverse array of sample holders and transfer fixtures is available to broaden the applications of users’ SDCOM, ensuring seamless compatibility with their workflow. Both manual and motorized wafer mapping stages are also at their disposal.

Image Credit: Malvern Panalytical Ltd

User-Friendly Precision

SDCOM achieves outstanding precision, reaching up to 0.01 degrees, dependent on the sample, and is capable of measuring crystals ranging from 1 mm and larger.

This high precision is sustained at top speeds, courtesy of the azimuthal scan method, offering comprehensive characterization of crystal orientation in a single measuring rotation. Additionally, there is an option to incorporate a lateral crystal direction marking function.

The SDCOM is user-friendly and easily accessible, thanks to manual handling and an intuitively designed software interface. This practicality makes it suitable for use in both research and industry, accommodating varying levels of user experience.

Image Credit: Malvern Panalytical Ltd

Cost-Effective

The X-Ray tube in SDCOM is air-cooled, eliminating the necessity for water cooling. The efficiency and compact design of SDCOM contribute to minimal energy consumption, thereby keeping your operational costs to a minimum.

Image Credit: Malvern Panalytical Ltd

Key Applications

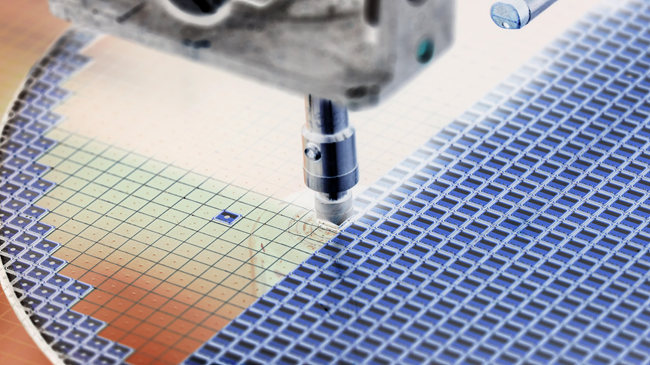

Marking and Measuring In-Plane Directions

SDCOM provides rapid and exceptionally accurate crystal orientation measurements, making it ideal for various applications in wafer production and processing, including marking and measuring in-plane directions. Its lightweight and portable design enables deployment wherever needed in the process.

With the ability to measure small crystals down to 1 mm with high precision and accommodate a diverse range of materials, SDCOM is well-suited to meet the dynamic and intricate requirements of the semiconductor industry.

Production Quality Control

Routine process control requires speed, precision, and repeatability, all of which SDCOM delivers. Its ultra-fast measurement speed enhances productivity without significantly affecting running costs, thanks to its desktop format and air-cooled X-Ray tube.

Materials Research

Capable of measuring a diverse range of crystal types within a compact laboratory space, SDCOM is well-suited for standard research workflows. In addition to the Azimuthal-scan, the SDCOM is equipped with a goniometer to measure Theta scans for maximum versatility.

Its running costs remain low due to minimized energy consumption and an air-cooled X-Ray tube that eliminates the need for water cooling. SDCOM is also user-friendly and easily accessible with manual handling, making it a practical solution for research laboratories with a diverse user base.

Specifications

Source: Malvern Panalytical Ltd

| . |

. |

| Orientation precision |

<0.001° |

| X-Ray source |

30 W air-cooled X-Ray tube, Cu anode |

| Detectors |

Scintillation counter technology |

| Sample holder |

Precise turntable, setting accuracy 0.01 °, customized sample holders, and transfer fixtures |

| Sample diameter |

Down to 2 mm ø, up to 200 mm |

| Ambient temperature |

≤ 30 °C |

| PC requirements |

Windows 10 or latest, . NET Framework update, 2 Ethernet ports |

| Power requirements |

100 to 230 V, single phase, 500 W |

| Dimensions |

600 mm (L) x 600 mm (B) x 840 mm (H) |

| Weight |

ca. 100 kg |

| Certification |

Manufactured under ISO 9001 guidelines, CE conform |

| All technical parameters are subject to changes based on R&D |