Malvern Panalytical’s Materials Research Diffractometers (MRD) have a long and successful history, and the generation of X’Pert³ MRD XL maintains this legacy. The new platform’s improved performance and dependability have increased analytical capabilities and power for X-Ray scattering research in:

- Advanced materials science

- Scientific and industrial thin film technology

- Metrological characterization in semiconductor process development

The X’Pert³ MRD XL offers full wafer mapping up to 200 mm, making it suitable for a variety of applications.

Features

Future-Proof System Flexibility

X’Pert³ MRD systems provide sophisticated and novel X-Ray diffraction solutions for research, process development, and control. The technologies employed enable all systems to be upgraded to all existing possibilities as well as future hardware and software advances.

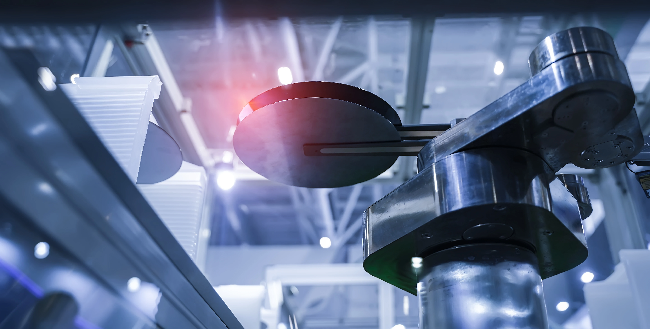

X’Pert³ Extended MRD (XL)

The X’Pert³ Extended MRD (XL) expands the versatility of X’Pert³ MRD devices. An additional PreFIX mounting platform enables the in-line mounting of an X-Ray mirror and a high-resolution monochromator, significantly increasing the incident beam intensity.

Thanks to the PreFIX concept, users can benefit from increased application versatility without sacrificing data quality, high-resolution X-Ray diffraction with high intensities, shorter measurement times for measurements like reciprocal space mapping, and the ability to rebuild from standard to extended configuration in minutes. The second-generation PreFIX simplifies reconfiguration, and optics alignment is more precise than ever.

X’Pert³ MRD (XL) In-Plane

The X’Pert³ MRD (XL) system allows in-plane diffraction measurements from lattice planes perpendicular to the sample surface.

Standard and in-plane geometries on one system and a diverse variety of diffraction studies on polycrystalline and perfect thin films are only two of the numerous advantages.

Smart Manager

Unleash the Potential of the Data

Instrumental data was frequently stored in manual records, spreadsheets, or site-specific servers. Users can maximize the X’Pert3 MRD XL’s performance by connecting it to the Smart Manager and continuously evaluating instrument data in the cloud. This is just one of the digital options available through Malvern Panalytical’s Smart Manager.

Smart Monitoring Support: Meet your proactive instrument guardian. Malvern Panalytical Smart Manager

Video Credit: Malvern Panalytical Ltd

Specifications

Source: Malvern Panalytical Ltd

| Enclosure |

| Dimensions |

1370 (w) x 1131 (d) x 1972 (h) mm

The system is on wheels for easy installation and relocation |

| Weight |

1150 kg |

| Regulations |

Meets all relevant worldwide regulations for electrical, mechanical, and X-Ray safety, with all anode types |

| Goniometer |

| Type |

Horizontal goniometer |

| Radius |

420 mm |

| Maximum usable range |

-40°< 2θ <160° (depending on accessories) |

| Encoders |

Direct optical encoding system for lifetime goniometer accuracy, using precisely aligned Heidenhain encoders |

| Long range accuracy |

±0.0025° |

| Short range (0.5°) accuracy |

±0.0004° |

| Angular reproducibility |

< 0.0002° |

| X-ray source/ Detectors/ Stages |

| Notes |

- Fully ceramic X-Ray tubes manufactured by Malvern Panalytical’s specialized factory under cleanroom conditions

- Tool-free swap of line-to-point focus

- 3 kW generator supporting all current and future X-Ray tubes

- Hybrid pixel detectors with the smallest pixel size (55 x 55 µm2) available on the market

- 5-axes cradle with 200 x 200 mm2 x, y translation

|

| Chi rotation |

±92° |

| Phi rotation |

2 x 360° |

| Smallest increment |

0.0001° |

Accessories

Detectors

PIXcel3D

The First Detector to Bring 0D-1D-2D and 3D Data to the Diffractometer

The PIXcel3D is a novel 2D solid-state hybrid pixel detector. Each pixel is 55 microns×55 microns, and the detector array is 256×256 pixels. Based on Medipix3 technology, the detector has an unsurpassed signal-to-noise ratio, thanks to its one-pixel point spread function and numerous energy discrimination levels.

Image Credit: Malvern Panalytical Ltd

General

X’Pert³ MRD XL Cleanroom Package

More Measuring Environments, Minimal Extra Investment

The X’Pert3 MRD XL Cleanroom Package includes smart solutions for the MRD XL, such as a fan filter unit, which can be retrofitted to an existing instrument or provided with a new one.

The MRD XL Cleanroom Package filters the air surrounding semiconductor wafer samples to prevent contamination when studying them. As a result, users can measure in an expanded range of environments without investing in a new instrument.

Image Credit: Malvern Panalytical Ltd

X’Pert³ MRD XL Automation

A Fully Automated Solution for Complex Layer Stack Metrology

Automation can be integrated into the current instrument as an extra software solution for the X'Pert3 MRD XL tool, enabling host control that complies with SECS/GEM standards.

Thanks to these additional features, the MRD XL system can fully utilize its versatility and flexibility in a host-controlled fabrication environment. This makes it possible to guarantee a production or research environment free from contamination.

Image Credit: Malvern Panalytical Ltd

Support

Support Services

- Performance certificates

- Hardware and software upgrades

- Local and global support

- Phone and remote support

- Preventive maintenance and checkups

- Flexible Customer Care Agreements

Expertise

- Turnkey solutions for elemental and structural semiconductor metrology

- Automation and consultancy

- Training and education

Key Applications

All-in-one X-Ray solution systems, the Malvern Panalytical X'Pert³ MRD and MRD XL have a wide range of industrial uses, such as:

Semiconductors and Single Crystal Wafers

Whether for growth studies or device design, measuring layer quality, thickness, strain, and alloy composition with high-resolution XRD has been crucial to research and development in electronic and optoelectronic multilayer semiconductor devices.

With a variety of X-Ray mirrors, monochromators, and detectors, the X’Pert3 MRD and MRD XL provide high-resolution configurations to fit varied materials systems, including lattice-matched semiconductors, relaxed buffer layers and unique exotic layers on non-standard substrates.

Polycrystalline Solids and Thin Films

Polycrystalline layers and coatings are essential to several thin films and multilayer devices. The evolution of polycrystalline layer shape during deposition is essential in functional materials research and development.

The X’Pert3 MRD and X’Pert3 MRD XL can be completely equipped with a variety of slits, parallel beam X-Ray mirrors, polycapillary lenses, crossed slits, and monocapillaries to provide a complete set of incident beam optics for reflectometry, stress, texture, and phase ID.

Ultra-Thin Films, Nanomaterials, and Amorphous Layers

Thin films that are amorphous, disordered, or nanocomposite can be found in functional devices. Due to their flexibility, many analytical techniques can be included in the X'Pert3 MRD and MRD XL systems.

There is a variety of high-resolution lenses, slits, and parallel plate collimators available to provide the best results for reflectometry, in-plane diffraction, and grazing incidence techniques.

Thin films that are disordered, amorphous, or nanocomposite can be used to create functional devices. The X’Pert3 MRD and MRD XL systems are flexible enough to incorporate numerous analysis methodologies. A variety of high-resolution lenses, slits, and parallel plate collimators are available to provide optimal performance for grazing incidence, in-plane diffraction, and reflectometry.

Measurement Under Non-Ambient Conditions

Examining materials' behavior under various circumstances is a crucial component of materials research and process development. Anton Paar’s DHS1100 non-ambient sample stage can be easily integrated into the X’Pert3 MRD and MRD XL, allowing for automated measurements under a variety of temperatures and in an inert environment.