To optimize Transmission Electron Microscopy (TEM) and Scanning Transmission Electron Microscopy (STEM) imaging, the acquisition of different signals at varying accelerating voltages for Energy-Dispersive X-Ray Spectroscopy (EDX) and Electron Energy Loss Spectroscopy (EELS) may be necessary.

While rules can vary depending on the sample, several general principles are commonly accepted. Firstly, the optimal imaging is typically achieved at the highest possible accelerating voltage above which visible damage will occur.

Secondly, EDX, especially during mapping, benefits from lower voltages with elevated ionization cross-sections. This results in better signal-to-noise ratio maps for a given total dose.

Thirdly, EELS performs better at higher voltages to mitigate multiple scattering, which can degrade the EELS signal with increasing sample thickness.

Acquiring data at various accelerating voltages from the same sample without losing the region of interest within a single microscopy session has not been possible—until now.

Imagine a Thermo Scientific Spectra 300 S/TEM:

- That can truly be operated at different voltages (all the voltages between 30 and 300 kV for which alignments were purchased) in a single microscopy session

- Where changing from an accelerating voltage to any other one takes about 5 minutes

- That can accommodate a radically different EDX concept with a 4.45 srad solid angle (4.04 srad solid angle with an analytical double tilt holder)

The Spectra Ultra S/TEM introduces a groundbreaking feature, in which the accelerating voltage becomes an adjustable parameter, akin to probe current. The powerful Ultra-X EDX system also allows for the chemical characterization of materials that are too beam-sensitive for traditional EDX analysis.

The Spectra Ultra aberration-corrected S/TEM provides an industry-leading degree of characterization capabilities for semiconductor and materials science applications, delivering the highest resolution across a diverse range of samples.

Built on an Ultra-Stable Foundation

The Spectra Ultra S/TEM is delivered on a platform manufactured to provide an unparalleled level of mechanical stability quality, achieved through both passive and optional active vibration isolation.

Similar to the Thermo Scientific Spectra 200 S/TEM and Spectra 300 S/TEM, the system is enclosed in a fully redesigned casing featuring a built-in on-screen display for convenient specimen loading and removal. It introduces full modularity and upgradeability, allowing seamless transitions between uncorrected and single-corrected configurations with variable heights for maximum flexibility in different room configurations.

Key Features

Fastest Time to Optimized Results From More Materials

The capability to switch accelerating voltage and achieve optimal stability of both optics and the specimen stage in under five minutes presents distinctive advantages, offering a faster and more innovative approach to operating the microscope for extracting optimized information from the specimen.

- The specimen's highest resolution spatial information (50 pm) can be collected at 300 kV. The system can be subsequently switched to reduced accelerating voltages for STEM EDX mapping, enhancing ionization cross sections in the same area and yielding higher X-Ray outputs. This approach contributes to minimized sample damage.

- In cases where specimens are susceptible to "knock-on" damage, the accelerating voltage can be switched multiple times within a single microscopy session. This strategy helps mitigate beam damage and ensures the preservation of data integrity.

This capability is realized through the incorporation of a significantly redesigned objective lens capable of maintaining constant power across all accelerating voltages ranging from 30 to 300 kV.

The introduction of the constant power concept, initially pioneered with the Titan TEM more than a decade and a half ago, allowed mode switching at a fixed accelerating voltage without inducing drift, thanks to the consistent thermal load on the objective lens. This innovative concept has now been expanded to encompass all voltage changes within the 30 to 300 kV range.

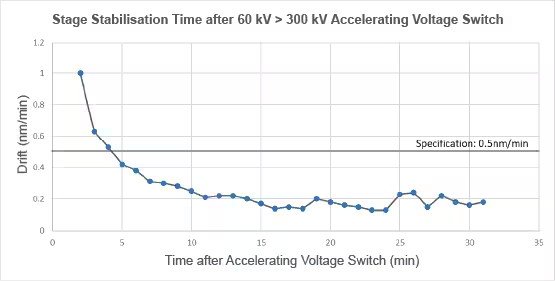

The objective lens generates magnetic fields that fluctuate significantly with different modes and accelerating voltages. However, the new objective lens of the Spectra Ultra (S)TEM maintains a constant thermal load consistently. The stabilization time of the optics and stage when transitioning between various accelerating voltages has been decreased from several hours to under five minutes.

The advantages of having flexibility in accelerating voltage, coupled with the Ultra-X detector, are evident. Rapid and adaptable control over the HT, in conjunction with Ultra-X, unlocks the potential for rapid imaging at the highest resolution along with optimized STEM EDX evaluation of beam-sensitive materials.

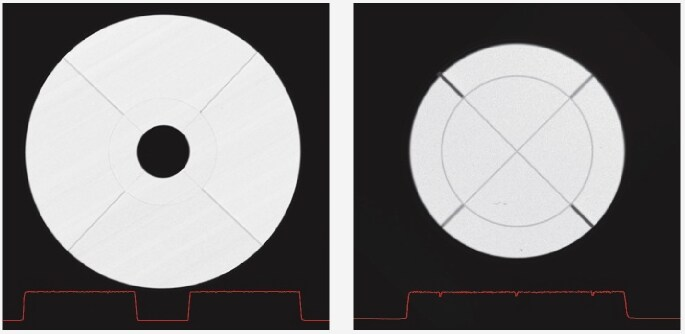

Stabilization of the stage after a switch from 60 to 300 kV. Image Credit: Thermo Fisher Scientific – Electron Microscopy Solutions

Lowest Dose STEM/EDX for the Characterization of More Materials

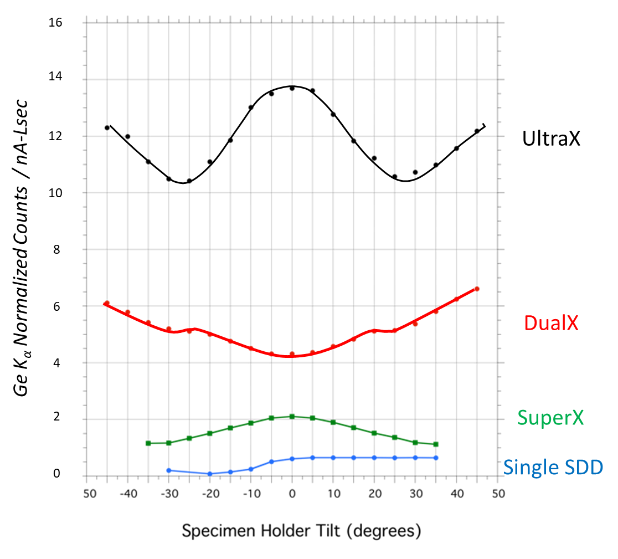

The Spectra Ultra S/TEM introduces the next era in EDX detection with the Ultra-X EDX detector. Offering a solid angle (>4.45 Sr) at least double that of any other EDX detector solution, the heightened sensitivity of Ultra-X unveils new capabilities in STEM EDX analysis. Even when accounting for the shadowing effects of an analytical double tilt holder, the solid angle remains >4.04 srad.

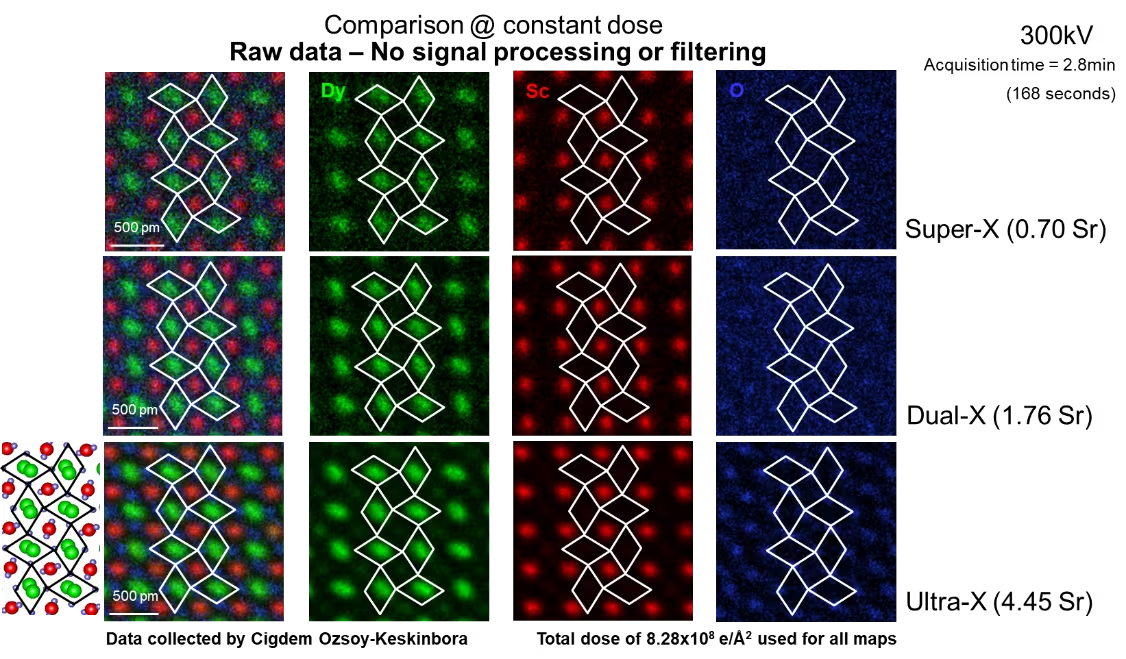

The advantages of such heightened sensitivity are demonstrated in the enhanced quality of spectrum imaging with Ultra-X. A comparison using the same electron dose (8.28 × 108 e/Å2) is shown between Super-X, Dual-X, and Ultra-X on a DyScO3 specimen. The enhancements in the signal-to-noise ratio, as evident in the raw data, are apparent. Ultra-X also allows for the direct imaging of the oxygen lattice, a capability not achievable with Super-X and Dual-X.

Figure 2. Normalized count rates as a function of tilt angle for a single detector, Super-X, Dual-X, and the new Ultra-X. Data was recorded at 200 kV with optimized specimen holders for each detector configuration. Image Credit: Zaluzec, et al. Submitted to Microscopy and Microanalysis, 2021.

Figure 3. A quantitative comparison is shown between Super-X, Dual-X, and Ultra-X on a DyScO3 specimen. The improvements in the signal-to-noise ratio are clearly seen. (Specimen courtesy of L.F. Kourkoutis, Cornell University). Image Credit: Thermo Fisher Scientific – Electron Microscopy Solutions

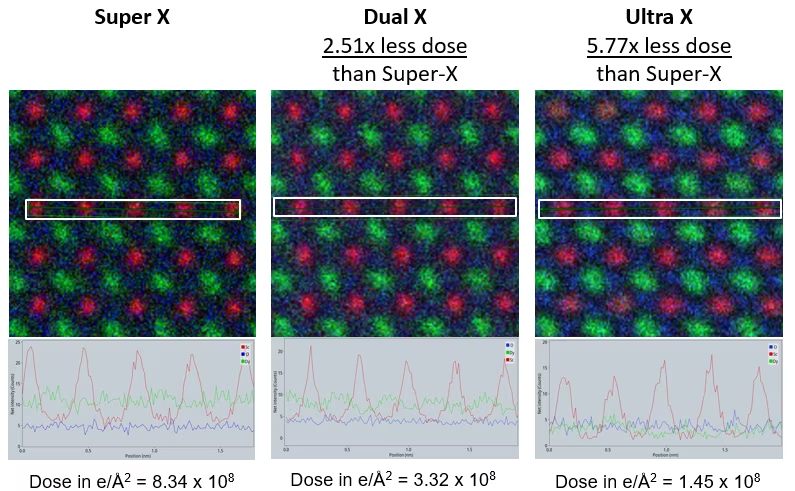

The exceptional sensitivity of Ultra-X also means that an equivalent level of chemical information can be acquired with only a fraction of the electron dose needed for alternative EDX detector solutions. This expands the potential for STEM EDX analysis on more beam-sensitive specimens and facilitates faster mapping on more stable specimens.

Figure 4. Comparable line profiles extracted from the spectrum images demonstrate that a similar signal-to-noise ratio can be obtained with Ultra-X with only a fraction of the electron dose needed for Super-X. Specimen courtesy of L.F. Kourkoutis, Cornell University. Image Credit: Thermo Fisher Scientific – Electron Microscopy Solutions

Unprecedented Sensitivity With the Panther STEM Detection System

STEM imaging on the Spectra Ultra S/TEM has undergone a transformation with the introduction of the Panther STEM detection system. This system comprises a new data acquisition architecture as well as two novel solid-state, eight-segment ring and a disk STEM detectors (16 segments in total). The redesigned detector geometry not only provides advanced STEM imaging capabilities but also offers the sensitivity to measure individual electrons.

Scanning image of the 16 segmented ring and disk detectors with an intensity profile (in red) proving the excellent homogeneity of sensitivity across the segments. Image Credit: Thermo Fisher Scientific – Electron Microscopy Solutions

The entire signal chain is meticulously optimized and tuned to deliver unparalleled signal-to-noise imaging capability with extremely low doses, enabling the imaging of beam-sensitive materials.

The entirely redeveloped data acquisition infrastructure can also combine various individual detector segments, with the potential for future combinations in arbitrary ways. This opens the door to novel STEM imaging methods, unveiling information not present in conventional STEM techniques. The architecture is scalable and provides an interface for synchronizing multiple STEM and spectroscopic signals.

![Comparison SrTiO₃ [001] HAADF images taken with the Panther STEM detection system with 3 pA, 1.3 pA and <1 pA of probe current. Even with probe currents <1 pA, the signal-to-noise ratio in the image allows automation routines like OptiSTEM+ to correct 1st and 2nd order aberrations in the probe forming optics, delivering sharp images](https://www.azom.com/images/equipments/EquipmentImage_8824_17059097916347504.png)

Comparison SrTiO₃ [001] HAADF images taken with the Panther STEM detection system with 3 pA, 1.3 pA, and <1 pA of probe current. Even with probe currents <1 pA, the signal-to-noise ratio in the image allows automation routines like OptiSTEM+ to correct 1st and 2nd order aberrations in the probe-forming optics, delivering sharp images. Image Credit: Thermo Fisher Scientific – Electron Microscopy Solutions

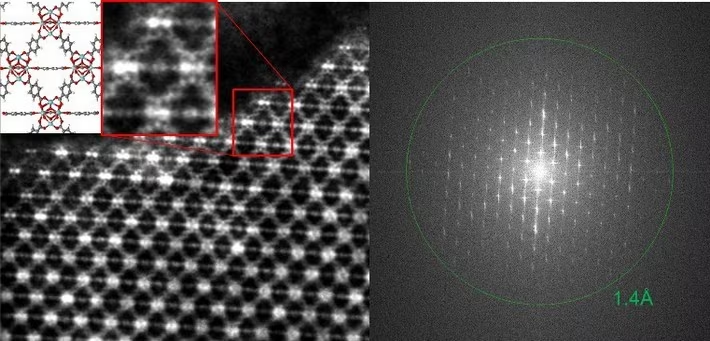

Extreme low-dose imaging of the metal organic framework (MOF) UiO 66. A probe current of <0.5 pA was used in combination with iDPC and the Panther STEM detection system to image atomic-level details in this highly dose-sensitive material with a spatial resolution of 1.4 Å. The image is a single shot with a frame time of 23.5 seconds. Specimen courtesy of Professor Y. Han, King Abdullah University of Science and Technology. (Data acquired on a Spectra 300 TEM.) Image Credit: Thermo Fisher Scientific – Electron Microscopy Solutions

Highest Resolution STEM Imaging Performance

The Spectra Ultra S/TEM features the innovative S-TWIN' (S-TWIN Prime) pole piece. Building upon the S-TWIN design, the S-TWIN' offers ultra-high spatial resolution in STEM, achieving 50 pm at 300 kV and 96 pm at 60 kV. It also provides a wide gap, accommodating experiments that necessitate large tilt angles or bulky in situ holders.

The S-TWIN' stands out in its capability to accommodate an exceptionally high solid-angle EDX solution without compromising spatial resolution. When combined with the improved mechanical stability of the base and the latest S-CORR probe corrector, the S-TWIN' matches the combined spatial resolution and high probe current specifications of the Spectra 300 TEM.

High-Energy Resolution and High-Brightness Sources

X-FEG/Mono or X-FEG/UltiMono

The Spectra Ultra S/TEM can be optionally equipped with a standard monochromator (X-FEG/Mono) or a high-energy resolution monochromator (X-FEG/UltiMono). Both monochromators undergo automatic excitation and tuning through a single-click operation to attain the highest energy resolution possible in each configuration, utilizing OptiMono or OptiMono+, respectively.

The X-FEG/Mono is capable of automatic tuning within the range of 1 eV down to 0.2 eV, while the X-FEG/UltiMono can be automatically tuned within the range of 1 eV down to <25 meV.

Both sources are designed to operate within the range of 30 to 300 kV, catering to the broadest spectrum of specimens. They can also be operated in standard mode with the monochromators switched off, catering to experiments demanding high brightness (such as STEM EDS mapping, ultra-high-resolution STEM, or high total current tasks like TEM imaging), without compromising other specifications.

This versatility allows the Spectra Ultra (S)TEM to seamlessly function in environments where a diverse range of experiments is anticipated on a single system.

X-CFEG

The Spectra Ultra S/TEM can be optionally powered by a new cold field emission gun (X-CFEG). The X-CFEG boasts exceptionally high brightness (>>1.0 × 108 A/m²/Sr/V*), a low energy spread (<0.4 eV), and the capability to operate within the range of 30 to 300 kV.

This configuration allows for simultaneous high-resolution STEM imaging with high probe currents, enabling high throughput and fast acquisition STEM analytics alongside high-energy resolution.

The potent combination of X-CFEG and the S-CORR probe aberration corrector enables sub-Angstrom (<0.8 Å) STEM-imaging resolution with over 1,000 pA of probe current to be routinely achieved.

![Si[110] HAADF images taken with the X-CFEG/S-CORR combination; probe currents range from 0.016 nA (left) up to 1 nA (right) while maintaining <76 pm STEM resolution.](https://www.azom.com/images/equipments/EquipmentImage_8824_17059098061848904.png)

Si[110] HAADF images taken with the X-CFEG/S-CORR combination; probe currents range from 0.016 nA (left) up to 1 nA (right) while maintaining <76 pm STEM resolution. Image Credit: Thermo Fisher Scientific – Electron Microscopy Solutions

Probe currents can also be dynamically tuned from <1 pA up to the nA range, with precise control of the gun and condenser optics. This fine-tuning is achieved with minimal impact on the probe aberrations, ensuring accommodation of the broadest range of specimens and experiments.

Like all cold field emission sources, the sharp tip of the X-CFEG requires periodic regeneration, referred to as flashing, to sustain the probe current. With the X-CFEG, the tip only needs to undergo flashing once per working day, a process that takes less than a minute.

Even under the highest resolution imaging conditions, there is no measurable impact on the probe aberrations, and the daily tip flashing process has no adverse effect on the tip's overall lifetime.

The latest generation X-CFEG generates a substantial total beam current (>14 nA), facilitating standard TEM imaging experiments, including in situ studies, with large parallel probes. This characteristic positions it as an exceptionally versatile yet high-performance C-FEG.

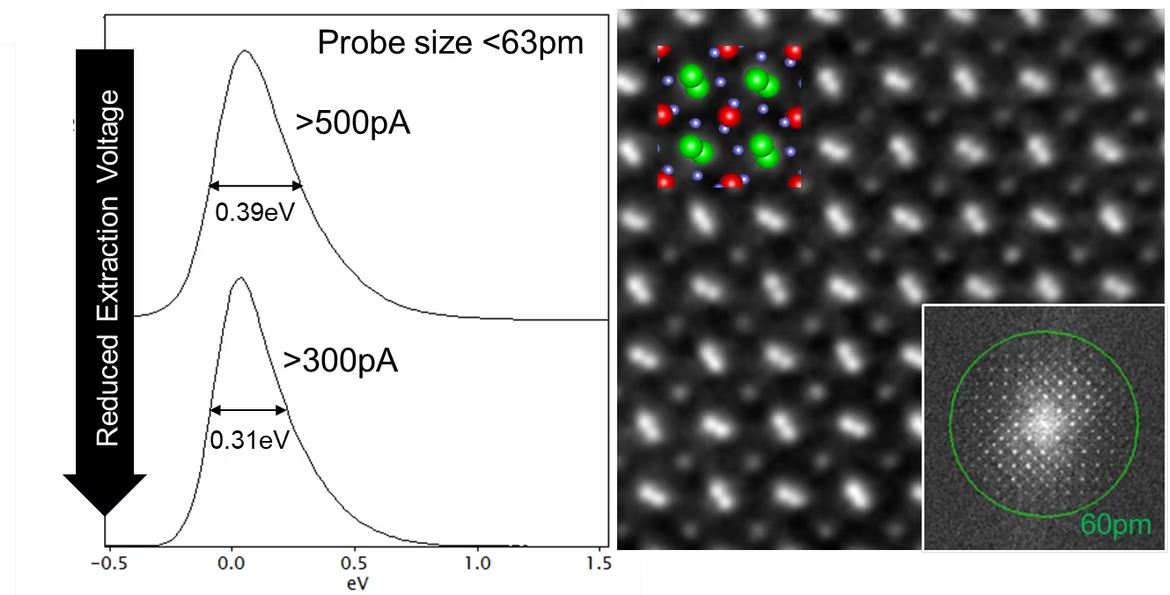

Adding to the flexibility of the X-CFEG is the ability to fine-tune the energy resolution by adjusting the extraction voltage.

In the provided example, the energy resolution was modulated between 0.39 eV, with <500 pA of probe current, and 0.31 eV, with >300 pA of probe current.

Maintaining elevated probe currents alongside high energy resolution enables detailed Energy Loss Near Edge Structure (ELNES) analysis without the necessity of a monochromator on core loss edges. The spatial resolution, as evidenced in the HAADF image of DyScO3, remains unaffected (in this case <63 pA).

This signifies that STEM EELS experiments with simultaneously high spatial resolution, energy resolution, and signal-to-noise ratio are now achievable.

The chosen extraction voltage for conducting the experiment has no impact on the lifetime of the tip.

The energy resolution of the ultra-high brightness X-CFEG can be adjusted using the extraction voltage. In the case above, it varied between 0.39 eV (with <500 pA of probe current) and 0.31 eV (with >300 pA of probe current). The spatial resolution, as demonstrated in the HAADF image of DyScO3, remains unaffected (in this case <63 pA). (Sample courtesy Professor L.F. Kourkoutis, Cornell University). Image Credit: Thermo Fisher Scientific – Electron Microscopy Solutions

Advanced STEM Imaging Capabilities

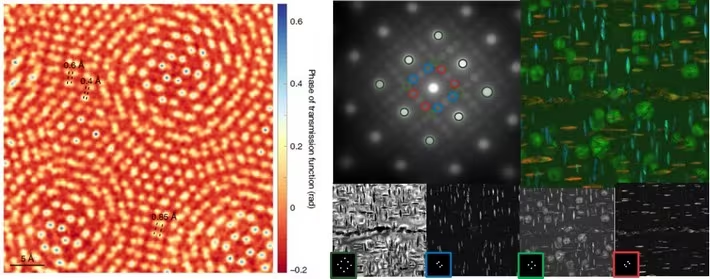

The Spectra Ultra S/TEM offers configuration options featuring either an Electron Microscope Pixel Array Detector (EMPAD) or a Thermo Scientific Ceta™ Camera with speed enhancement for the collection of 4D STEM data sets.

The EMPAD is capable of 30–300 kV and provides a high dynamic range (1:1,000,000 e- between pixels), high signal-to-noise ratio (1/140 e-), and high speed (1,100 frames per second) on a 128 × 128-pixel array. This makes it the optimal detector for 4D STEM applications—for instance, where the details of the central and diffracted beams need to be analyzed simultaneously, as in the following ptychography image.

The EMPAD detector can be used for a wide variety of applications. On the left, it is used to extend spatial resolution (0.39 Å) beyond the aperture-limited resolution at low accelerating voltages (80 kV) in a bi-layer of the 2D material MoS₂ (Jiang, Y. et al. Nature 559, 343–349, 2018). On the right, it is used to independently image dark field reflections, revealing the complex microstructure of the precipitates in a superalloy (Sample courtesy Professor G. Burke, University of Manchester). Image Credit: Thermo Fisher Scientific – Electron Microscopy Solutions

The Ceta Camera with speed enhancement serves as an alternative for 4D STEM applications that demand a higher pixel count, particularly when each point in the STEM scan needs to be combined with EDS analysis. This configuration offers higher resolution diffraction patterns, reaching up to a 512 × 512-pixel resolution, making it well-suited for applications such as strain measurement.

In Situ Capabilities of the Spectra Ultra S/TEM

The Spectra Ultra S/TEM accommodates a diverse array of holders for in situ experiments, thanks to its versatile S-TWIN’ wide-gap pole piece. The Thermo Scientific NanoEx Holder family seamlessly integrates with the microscope, allowing MEMS device-based heating for atomic imaging at elevated temperatures.

Below, gold nanoparticles are heated to 700 ºC, and their resulting motion is simultaneously captured at a rate exceeding 30 frames per second with full frame 4 k by 4 k pixel resolution on a Ceta Camera with speed enhancement. This setup yields high spatial and temporal resolution, enabling the detailed observation of highly dynamic molecular behavior.

Specifications

Source: Thermo Fisher Scientific – Electron Microscopy Solutions

| . |

. |

|

Uncorrected

|

- Energy spread: 0.2–0.3 eV

- Information limit: <100 pm

- STEM resolution: <136 pm

|

|

Probe corrected

|

- Energy spread: 0.2–0.3 eV

- Information limit: <100 pm

- STEM resolution: <50 pm (125 pm @ 30 kV)

|

|

Probe+Image Corrected X-FEG/Mono

|

- Energy spread: 0.2–0.3 eV

- Information limit: <60 pm

- STEM resolution: <50 pm at 300 kV with >30 pA of probe current

STEM resolution: <125 pm at 30 kV with >20 pA of probe current

|

|

Probe+Image Corrected X-FEG/UltiMono

|

- Energy spread: 0.05 eV (0.025 eV @ 60 kV)

- Information limit: <60 pm

- STEM resolution: <50 pm at 300 kV >30 pA of probe current

STEM resolution: <125 pm at 30 kV with >20 pA of probe current

|

|

Probe+Image Corrected X-CFEG

|

- Energy spread: 0.4 eV

- Information limit: <70 pm

- STEM resolution: <50 pm (<136 pm @ 30 kV) with >100 pA of probe current

|

|

Source

|

- X-FEG Mono: High-brightness Schottky field emitter gun and monochromator with a tunable energy resolution range between 1 eV and <0.2 eV

- X-FEG UltiMono: High-brightness Schottky field emitter gun with ultra-stable monochromator and accelerating voltage with a tunable energy resolution range between 1 eV and <0.05 eV (<0.025 eV @ 60 kV)

- X-CFEG: Ultra-high brightness with an intrinsic energy resolution of <0.4 eV with 14 nA of total beam current and <0.3 eV with 2 nA of total beam current

- Flexible high-tension range from 30 – 300 kV

|