The Thermo Scientific Quattro ESEM offers comprehensive performance in both imaging and analytics, featuring a distinctive environmental mode (ESEM) that enables the examination of samples in their natural state.

This model is ideal for various academic, industrial, and government labs that want the versatility and ease of use required for users of varying experience levels and disciplines on a platform that supports unique in situ experiments.

To ensure excellent resolution, the Quattro ESEM features a field emission gun (FEG). Meanwhile, its three vacuum modes (high vacuum, low vacuum, and ESEM) offers the flexibility to accommodate the widest range of samples of any SEM currently on the market, including those that are outgassing or otherwise not vacuum-compatible.

Best in Class for In Situ Imaging Capabilities, Dynamic Experiments with Excellent Analytical Capabilities

The Quattro ESEM is a highly flexible platform for in situ dynamic experiments. Thanks to its environmental SEM capability, the Quattro ESEM enables scientists to study materials in a variety of conditions, such as wet/humid, hot, or reactive environments, as they develop new materials and products. It also supports heating and cooling experiments both in high vacuum and low vacuum to accommodate the widest range of needs.

Experiments involving the cooling of wet materials can be conducted using either the Peltier cooling stage or, for transmission mode requirements, with Thermo Scientific WetSTEM Technology. In Addition, Furthermore, the Quattro ESEM offers various options for heating samples, applicable to both bulk materials and powders.

Users can perform dynamic experiments at high temperatures both in high vacuum (with the high-vacuum heating stage), in low-vacuum/ESEM mode (with the two ESEM heating stages for temperatures up to 1,000 °C and 1,400 °C), and on a localized area for better control of the temperature change (with the Thermo Scientific µHeater Holder).

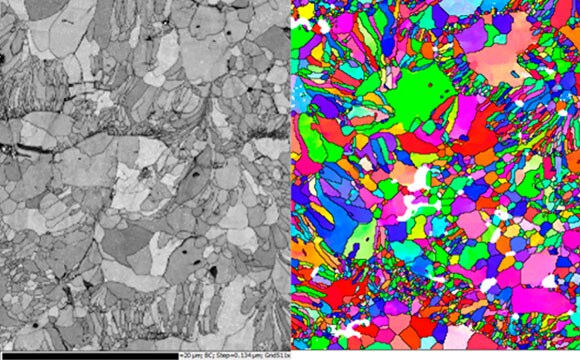

Thanks to its chamber capacity, a range of accessories can be used with the Quattro ESEM. Its analytical capabilities also encompass wavelength dispersive X-Ray spectroscopy (WDS), electron backscatter diffraction (EBSD) coplanar with EDS, and energy dispersive X-Ray spectroscopy (EDS) with ports for 180-degree dual EDS attachment.

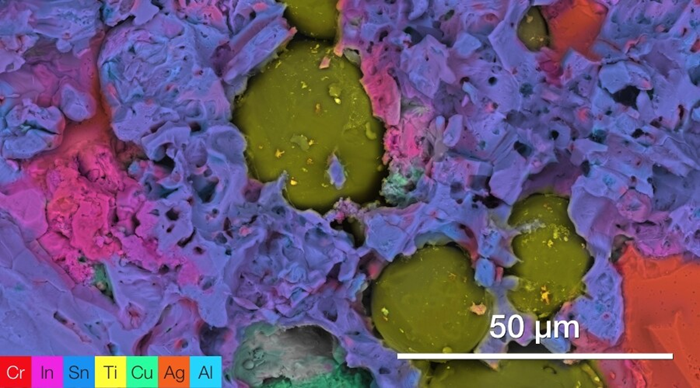

Moreover, the Quattro ESEM is equipped with the innovative Thermo Scientific ChemiSEM Technology. This feature introduces live elemental imaging directly integrated into the SEM user interface, offering constant access to compositional data through an exceptionally user-friendly interface.

Diverse Material Application Observed with the Quattro ESEM

Metals and alloys (metallic filter). Image Credit: Thermo Fisher Scientific – Electron Microscopy Solutions

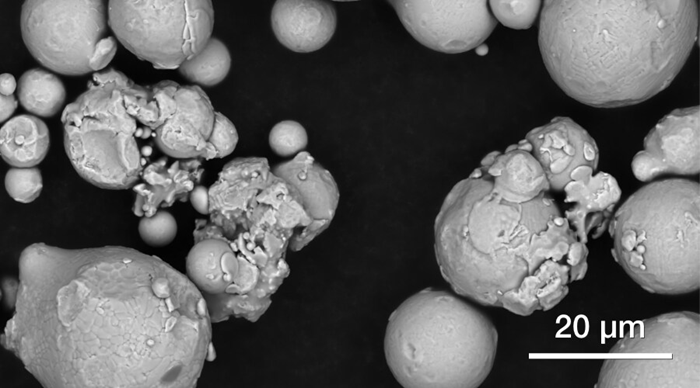

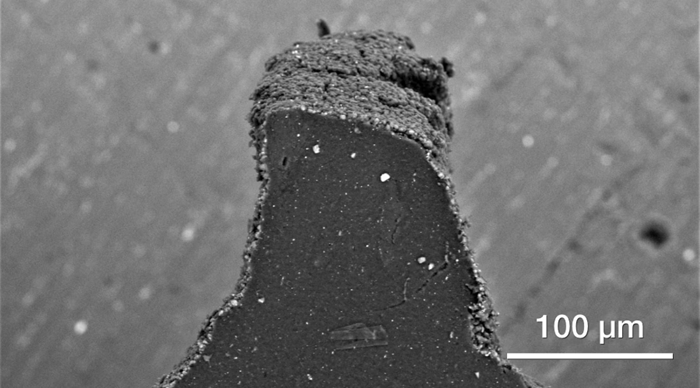

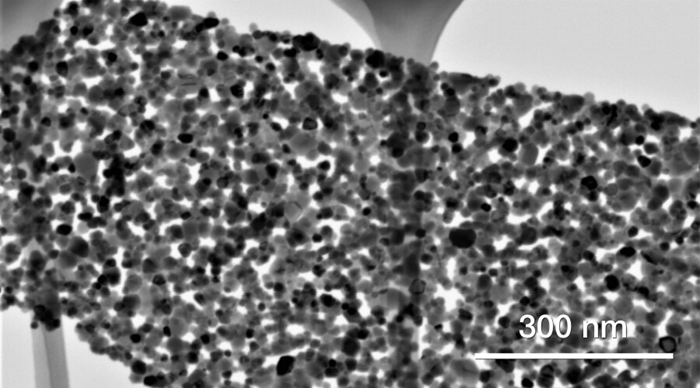

Additive manufacturing powder. Image Credit: Thermo Fisher Scientific – Electron Microscopy Solutions

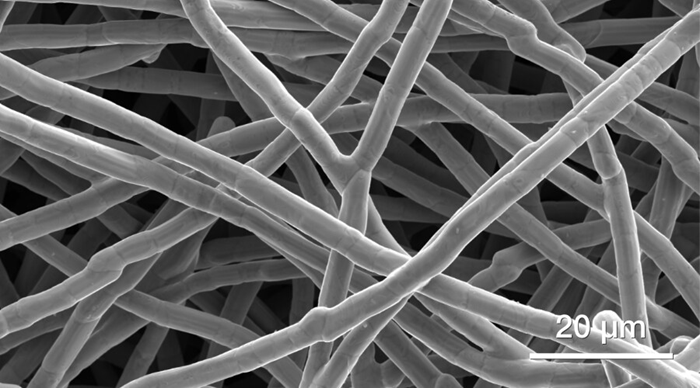

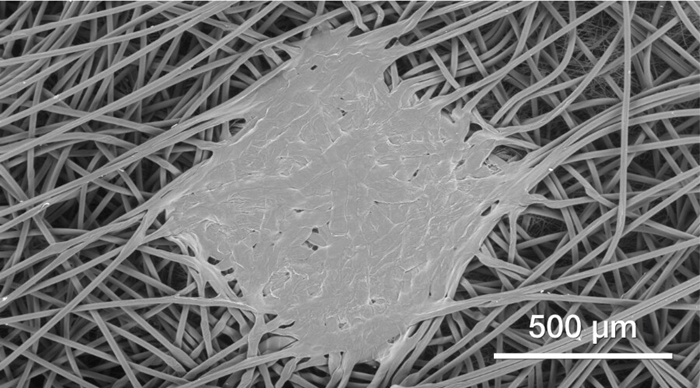

Soft materials (polymeric fibers). Image Credit: Thermo Fisher Scientific – Electron Microscopy Solutions

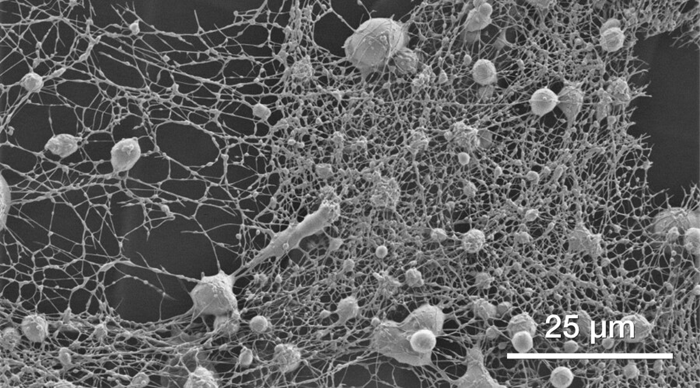

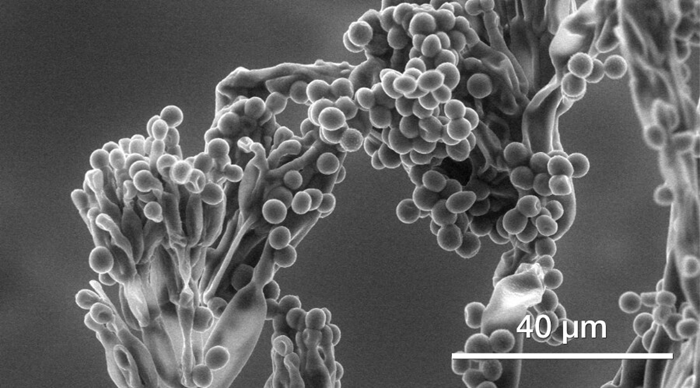

Biological samples (mold spores). Image Credit: Thermo Fisher Scientific – Electron Microscopy Solutions

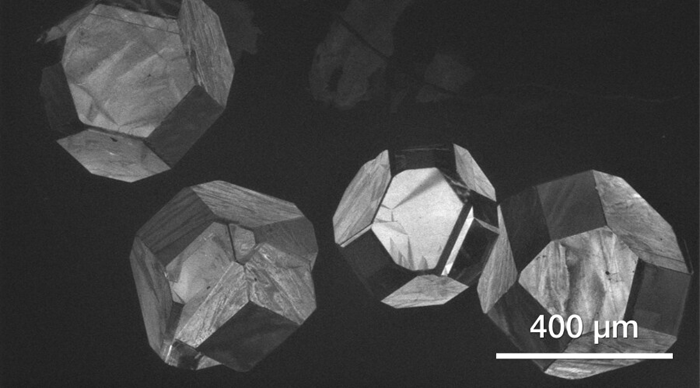

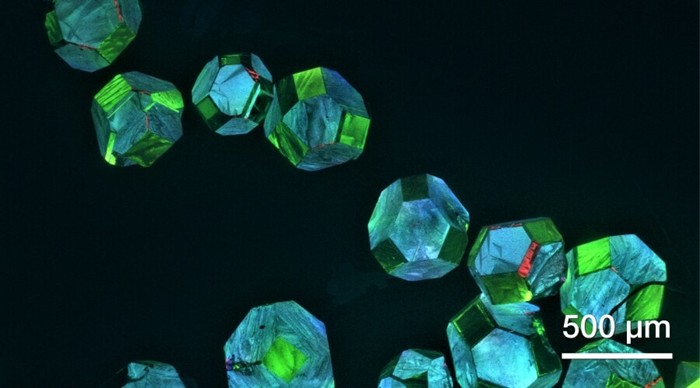

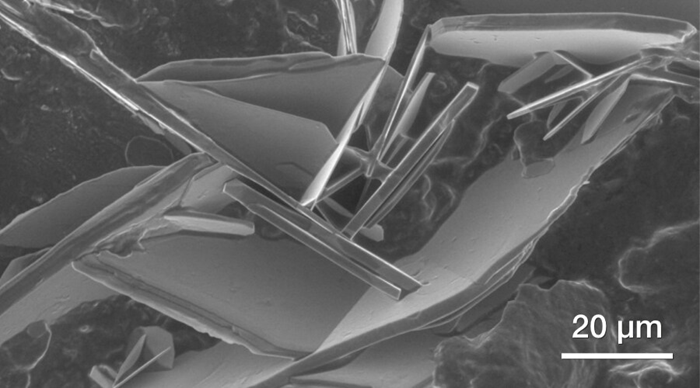

Geological materials (diamonds). Image Credit: Thermo Fisher Scientific – Electron Microscopy Solutions

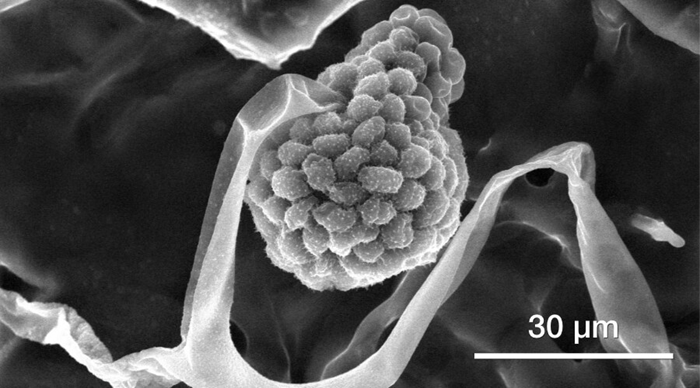

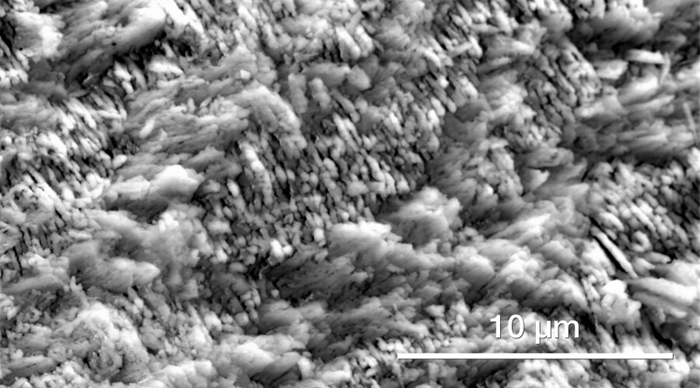

Minerals (shell’s surface). Image Credit: Thermo Fisher Scientific – Electron Microscopy Solutions

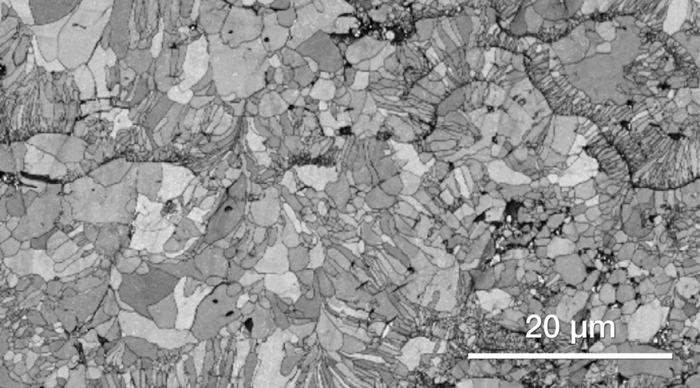

Ceramics (zirconia in a thermal barrier coating). Image Credit: Thermo Fisher Scientific – Electron Microscopy Solutions

Soft materials (cross-section of a tire). Image Credit: Thermo Fisher Scientific – Electron Microscopy Solutions

Chemicals (zinc oxide nanoparticles assembled into platelets). Image Credit: Thermo Fisher Scientific – Electron Microscopy Solutions

Quattro Environmental Scanning Electron Microscope Features

Dynamic In-Situ Experiments

In situ study of materials in their natural state: unique high-resolution FEG-SEM with environmental mode (ESEM). It allows for in situ analysis at temperatures spanning from -165 °C to 1,400 °C, facilitated by a selection of cryo, Peltier, and heating stages.

Peltier cooling experiment of sodium sulfate crystals in sandstone. Video Credit: Thermo Fisher Scientific – Electron Microscopy Solutions

An in situ cooling experiment carried out on a sample of sandstone containing sodium sulfate crystals. The experiment’s goal was to investigate the behavior of sodium sulfate at full saturation. The temperature was kept at 2 ˚C by varying the pressure up to 700 Pa. Samples were provided by the Academy of Science, Czech Republic’s Institute of Theoretical and Applied Mechanics.

μHeater Holder heating experiment of magnetite and hematite. Video Credit: Thermo Fisher Scientific – Electron Microscopy Solutions

A heating experiment carried out using the μHeater Holder. The video shows the heating of a mix of magnetite and hematite from 40 ˚C up to 1,000 ˚C.

Wide Range of Information

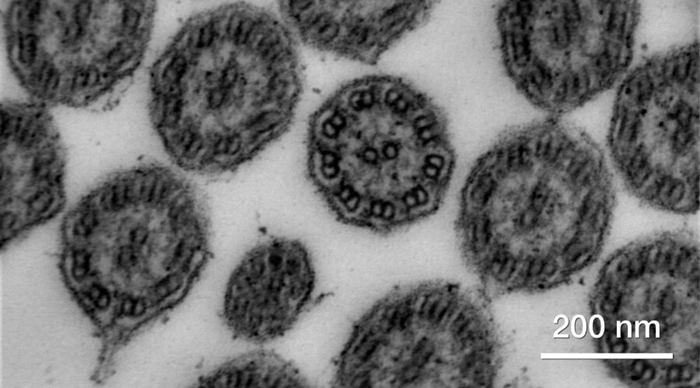

Users can observe all information from all samples with simultaneous SE and BSE imaging in every mode of operation. Several additional detectors, such as the STEM3+ detector and the retractable RGB cathodoluminescence (CL) detector, are available to help accommodate the needs of every single user and offer a complete set of information from a wide range of materials.

Material contrast from a mix of different metals. Image Credit: Thermo Fisher Scientific – Electron Microscopy Solutions

Bright-field (BF) STEM3+ image of a biological section of a planarian. Image Credit: Thermo Fisher Scientific – Electron Microscopy Solutions

CL image of diamonds. Image Credit: Thermo Fisher Scientific – Electron Microscopy Solutions

Excellent Analytical Capabilities

Outstanding analytical capabilities with a flexible chamber that can accommodate multiple EDS, EBSD, or WDS detectors. Elemental information is available at your fingertips thanks to Thermo Scientific's ChemiSEM Technology, which offers live, quantitative, elemental mapping for unprecedented ease of use and time to result.

The Quattro ESEM's through-the-lens pumping enables precise EDS and EBSD analysis of non-conductive samples, even in low vacuum conditions.

ChemiSEM image of dental filling material, showing a mixture of Hg, Cu, Sn and Ag. Image Credit: Thermo Fisher Scientific – Electron Microscopy Solutions

EBSD on ceramic materials in low vacuum. Image Credit: Thermo Fisher Scientific – Electron Microscopy Solutions

Minimize Sample Preparation Time with the Unique Combination of High-Vacuum, Low-Vacuum, and Environmental Modes

Polymeric fibers (low vacuum imaging, 80 Pa). Image Credit: Thermo Fisher Scientific – Electron Microscopy Solutions

Hydrated mold spores (ESEM imaging, 800 Pa). Image Credit: Thermo Fisher Scientific – Electron Microscopy Solutions

Salts on bacon (ESEM imaging, 700 Pa). Image Credit: Thermo Fisher Scientific – Electron Microscopy Solutions

Ease of Use with Innovative Options and Advanced Automation

Easy to use, intuitive software with User Guidance. The unique Undo function allows for the efficient exploration of imaging conditions, speeding up the process thanks to a couple of clicks of a mouse.

Optimize work and explore the imaging condition with the unique Undo function. Video Credit: Thermo Fisher Scientific – Electron Microscopy Solutions

Advanced Automation

Depending on the specific application requirements, advanced automation can be provided in different ways, with either Thermo Scientific AutoScript 4 Software or Thermo Scientific Maps Software.

The Quattro ESEM can be controlled with AutoScript 4 software. Utilize an application programming interface (API) based on Python to record and monitor dynamic parameters like temperature, stage location, or pressure or to optimize in situ cooling or heating studies.

Maps Software automates large-area acquisition on numerous samples using up to four simultaneous signals. In addition to a clear increase in system productivity, it offers a multi-scale, multi-layered visualization environment in which 2D and 3D data and imagery can be imported from any source to correlate different modalities.

Live drift compensation with AutoScript 4 Software on an ESEM heating stage experiment. Video Credit: Thermo Fisher Scientific – Electron Microscopy Solutions

ESEM heating stage experiment on a silver wire, heated from 300 ˚C to 530 ˚C. AutoScript 4 Software was used to obtain a live drift compensation through a combination of beam shift and stage moves. This approach yielded a consistent and stable image of the silver wire throughout the entire duration of the recording, even as the wire changed its position on the substrate.

Product Specifications

Source: Thermo Fisher Scientific – Electron Microscopy Solutions

| . |

. |

| Resolution |

- High-vacuum imaging

- 0.8 nm at 30 kV (STEM)

- 1.0 nm at 30 kV (SE) in high vacuum

- 1.3 nm at 30 kV (SE) in low vacuum and ESEM mode

- 3.0 nm at 1 kV (SE)

|

| Standard detectors |

- ETD, low-vacuum SED (LVD), gaseous SED for ESEM mode (GSED), IR camera

|

| Optional detectors |

- Nav-Cam+, DBS, DBS-GAD, ESEM-GAD, ICD, STEM 3+, WetSTEM, RGB-CLD, EDS, EBSD, WDS, Raman, EBIC, etc.

|

| ChemiSEM Technology (optional) |

- Live quantitative SEM image coloring is available based on energy-dispersive X-ray spectroscopy (EDS). Point & ID, linescan, region, element maps and accurate Noran quantification are included.

|

| Stage bias (beam deceleration, optional) |

|

| Low vacuum mode |

- Up to 2600 Pa (H2O) or 4000 Pa (N2)

|

| Stage |

- 5-axis motorized eucentric stage, 110 x 110 mm2 with a 105° tilt range. Maximum sample weight: 5 kg in un-tilted position.

|

| Standard sample holder |

- Standard multi-sample SEM holder uniquely mounts directly onto the stage, hosts up to 18 standard stubs (⌀ 12 mm), does not require tools to mount a sample

|

| Chamber |

- 340 mm inside width, 12 ports, three simultaneous EDS detectors possible, two at 180°, coplanar EDS/EBSD orthogonal to the tilt axis of the stage

|

| In situ accessories (optional) |

- Software controlled -20 °C to +60 °C Peltier cold stage

- Software controlled 1000 °C low vacuum/ESEM heating stage

- Software controlled 1100 °C high vacuum heating stage

- Software controlled 1400 °C low vacuum/ESEM heating stage

- Integrated gas injection: up to 2 units (other accessories may limit number of GIS available) for beam-induced deposition of the following materials:

- Manipulators

- Cryo-stage

- Electrical probing / multi-probing stations

|

| Software options |

- Maps Software for automatic large area acquisition using tiling and stitching; correlative work

- AutoScript 4 Software; a Python-based application programming interface

- Pattern generation software

- Thermo Scientific TopoMaps Software for image colorization, image analysis and 3D surface reconstruction

|